Powdered alloy material for Fe-based non-magnetic clad layer

A technology of alloy powder and cladding layer, which is applied in the field of multi-element alloy powder materials and preparation, to achieve the effects of small spatter, smooth and uniform surface, and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

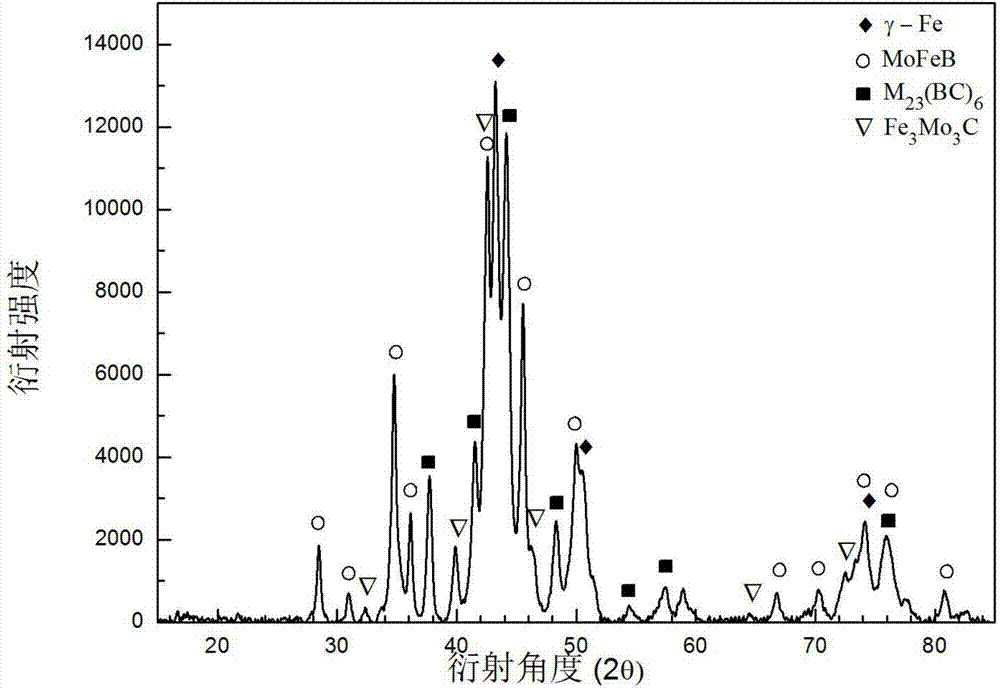

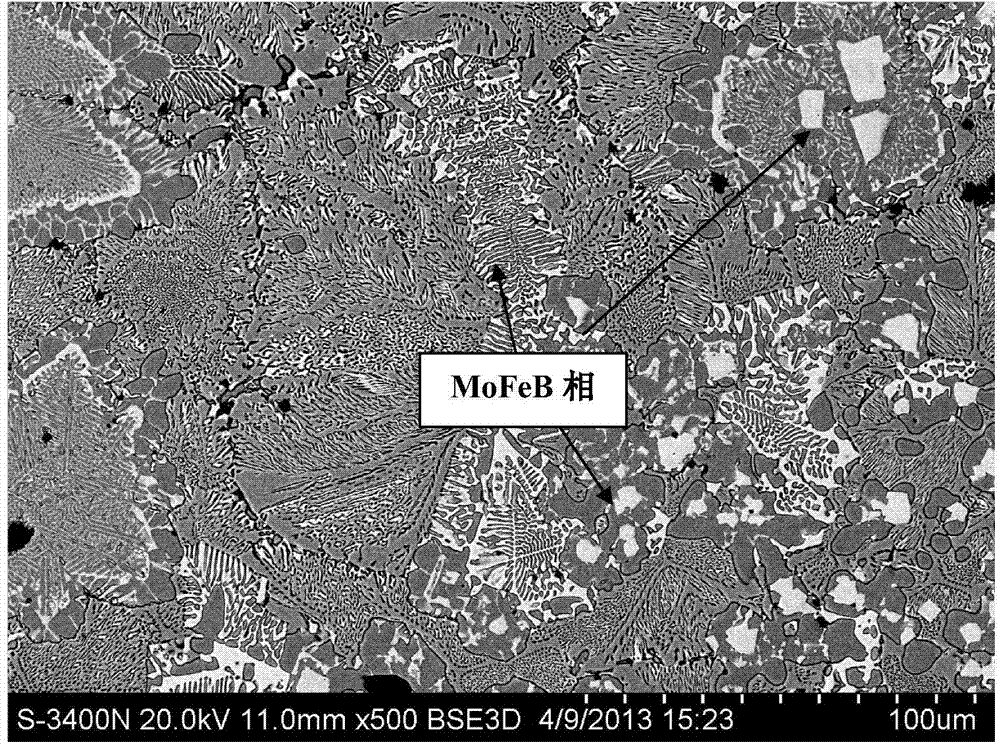

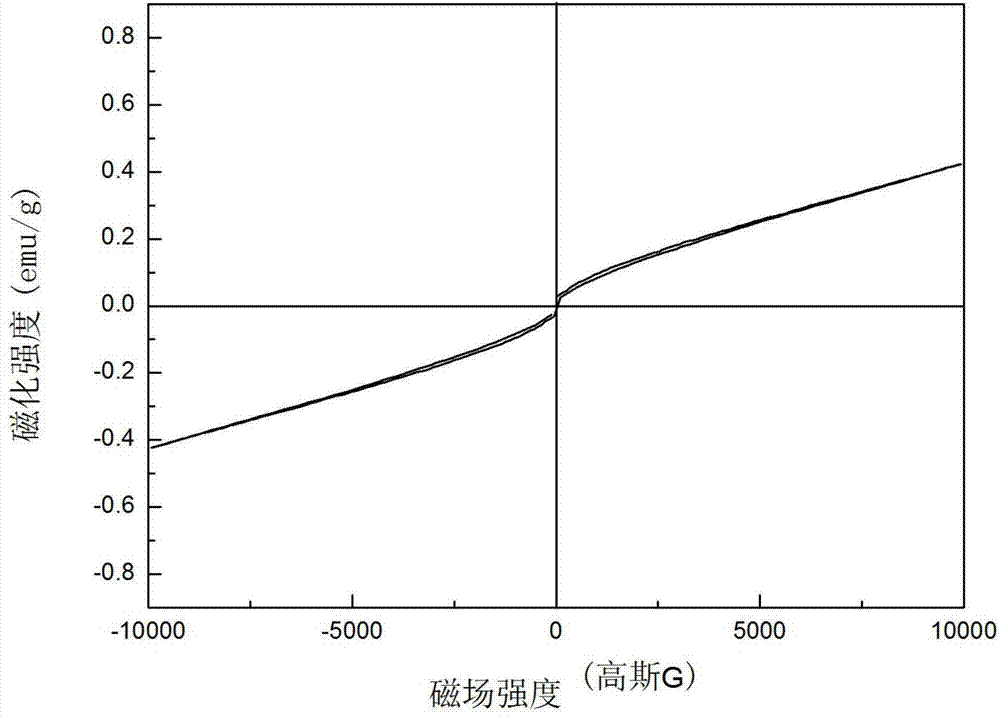

Embodiment 1

[0034] According to the mass percentage of Fe-based multi-element alloy powder: Cr: 6wt.%; Mo: 10wt%; C: 2.0wt.%; B: 1.5wt.%; W: 2.5wt.%; Fe: margin. Plasma arc surfacing welding parameters used to prepare cladding layer: transferred arc voltage 29-31V; transferred arc current 90A; spraying distance 13mm; ion gas (Ar): 250L / h; powder feeding gas (Ar): 245 / h; shielding gas (Ar): 380L / h; Powder feeding voltage: 6.3V.

Embodiment 2

[0036] According to the mass percentage of Fe-based multi-element alloy powder: Cr:8wt.%; Mo:8wt%; C:1.5wt.%; B:1.8wt.%; W:2.8wt.%; Mn:6.8wt.%, Fe: margin. Plasma arc surfacing welding parameters used to prepare the cladding layer: transferred arc voltage 29-31V; transferred arc current 90A; spraying distance 13mm; ion gas (Ar): 260 / h; powder feeding gas (Ar): 260L / h; shielding gas (Ar): 400L / h; Powder feeding voltage: 6.3V.

Embodiment 3

[0038] According to the mass percentage of Fe-based multi-element alloy powder: Cr: 13wt.%; Mo: 6.5wt%; C: 1.8wt.%; B: 2.0wt.%; W: 4wt.%; Fe: margin. Plasma arc surfacing welding parameters used to prepare cladding layer: transferred arc voltage 29-31V; transferred arc current 90A; spraying distance 13mm; ion gas (Ar): 270L / h; powder feeding gas (Ar): 270L / h; shielding gas (Ar): 420L / h; Powder feeding voltage: 6.3V.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com