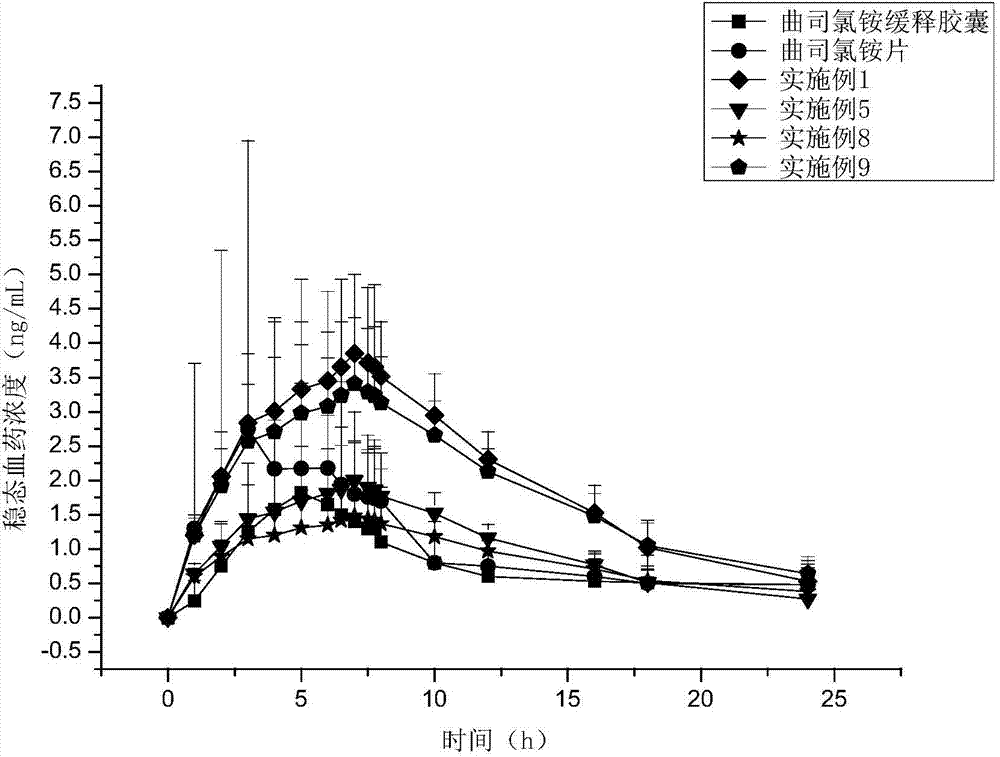

Trospium chloride double-release capsules and preparation method thereof

A technology of trospium chloride and double release is applied in the field of sustained-release capsules and preparation thereof, which can solve the problems of increasing drug cost, low bioavailability, increasing the risk of drug compatibility and the like, and achieves improvement of drug safety and blood drug concentration. Smooth and easy long-term treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1: trospium chloride double-release capsules and preparation method thereof

[0049] The preparation method of trospium chloride double-release capsules comprises the following steps:

[0050] (1) Pellet drug loading: adopt the fluidized bed (Chongqing Jinggong Pharmaceutical Machinery Co., Ltd., DPL 1 / 3) cutting spray process, the air inlet temperature is 40°C, the air inlet frequency is 25HZ, and the atomization pressure is 0.1MPa. (2)-(4) Same as this, according to the proportioning shown in table 1, take trospium chloride crude drug, adhesive and anti-tack agent, with 80% ethanol aqueous solution as solvent, the preparation weight volume percentage content is 20% drug-loaded coating solution, drug-loaded on 30-35 mesh sucrose cores;

[0051] (2) Isolation layer coating: according to the proportion shown in Table 1, the isolation layer material (EG-05 series) was weighed, and 80% ethanol aqueous solution was used as a solvent to prepare an isolation layer...

Embodiment 2

[0056] Embodiment 2: trospium chloride double-release capsules and preparation method thereof

[0057] The preparation method of trospium chloride double-release capsules comprises the following steps:

[0058] (1) Pellet drug loading: adopt the fluidized bed (Chongqing Jinggong Pharmaceutical Machinery Co., Ltd., DPL 1 / 3) cutting spray process, the air inlet temperature is 60°C, the air inlet frequency is 30HZ, and the atomization pressure is 0.3MPa. (2)-(4) Same as above, according to the proportioning shown in table 1, take trospium chloride bulk drug, adhesive and anti-tack agent, take pure water as solvent, the preparation weight volume percentage content is 30% The drug-loaded coating solution is loaded on the 30-35 mesh sucrose core;

[0059] (2) Isolation layer coating: adopt fluidized bed (Chongqing Jinggong Pharmaceutical Machinery Co., Ltd., DPL 1 / 3) bottom spray process, according to the proportion shown in Table 1, take the isolation layer material (PVA103), with...

Embodiment 3

[0064] Embodiment 3, trospium chloride double release capsule and preparation method thereof

[0065] The preparation method of trospium chloride double-release capsules comprises the following steps:

[0066] (1) Pellet drug loading: adopt the fluidized bed (Chongqing Jinggong Pharmaceutical Machinery Co., Ltd., DPL 1 / 3) cutting spray process, the air inlet temperature is 80°C, the air inlet frequency is 40HZ, and the atomization pressure is 0.2MPa. (2)-(4) with this, according to the proportioning shown in table 1, take trospium chloride crude drug, adhesive and anti-tack agent, be the ethanol aqueous solution of 50% with volume percentage concentration as solvent, Prepare a drug-loaded coating solution with a weight-volume percentage of 40%, and load the drug on 30-35 mesh sucrose cores;

[0067] (2) Isolation layer coating: adopt fluidized bed (Chongqing Jinggong Pharmaceutical Machinery Co., Ltd., DPL 1 / 3) bottom spraying process, according to the proportion shown in Tab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com