Vessel stent and production method thereof

A pipeline stent and tubular technology, applied in the field of medical devices, can solve the problems of involving the brachiocephalic trunk, left common carotid artery, left subclavian artery, rapid endothelialization of unfavorable tissues, limited mesh density of stents, etc. effect of promoting rapid endothelialization, reducing the risk of aneurysm rupture, and promoting rapid endothelialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

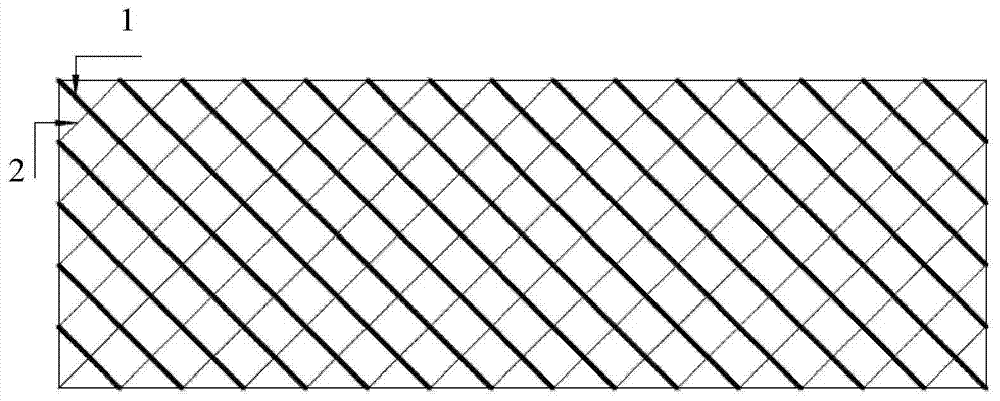

[0029] figure 1 Shown is a plan view of a pipe support embodiment of the present invention. The pipe support is composed of two materials namely material 1 and material 2. Among them, material 1 is a shape memory alloy wire, in this case, nickel-titanium wire with a wire diameter of 0.0014 inches, and material 2 is a biodegradable fiber wire, in In this case polylactic acid (PLA), the wire diameter is 0.0012 inches. The two kinds of wires are interwoven in a weaving manner to form a net. The two kinds of wires in the net are arranged in a ratio of 1:1, and the number of wire ends of material 1 and material 2 is 24 each.

Embodiment 2

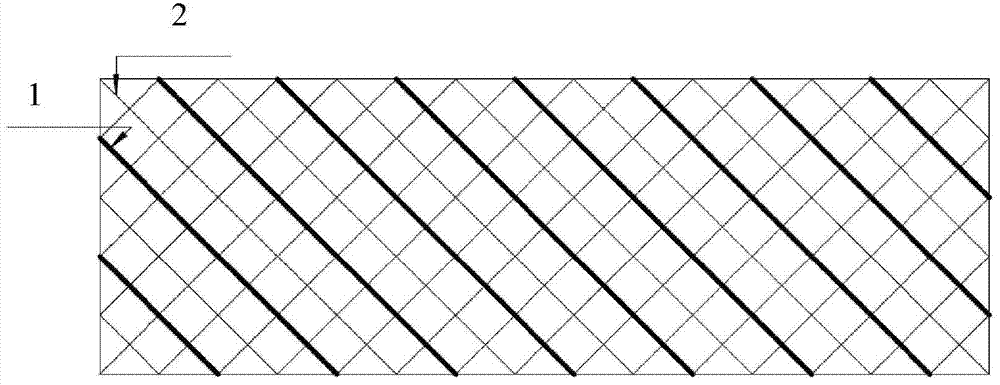

[0031] figure 2 Shown is a plan view of a pipe support according to another embodiment of the present invention. The pipe support frame is formed into a net-shaped tubular structure, which is composed of two materials, namely material 1 and material 2, wherein material 1 is a shape memory alloy wire, in this case, nickel titanium wire with a wire diameter of 0.0014 inches, and material 2 is biological The degradable fiber filaments, in this case polyglycolide lactide (PGLA), are 0.0012 inches in diameter. The two kinds of wires are interwoven with each other to form a net. The ratio of material 1 and material 2 in the net is arranged in a ratio of 1:3, and the total number of wire ends of material 1 and material 2 is 48.

Embodiment 3

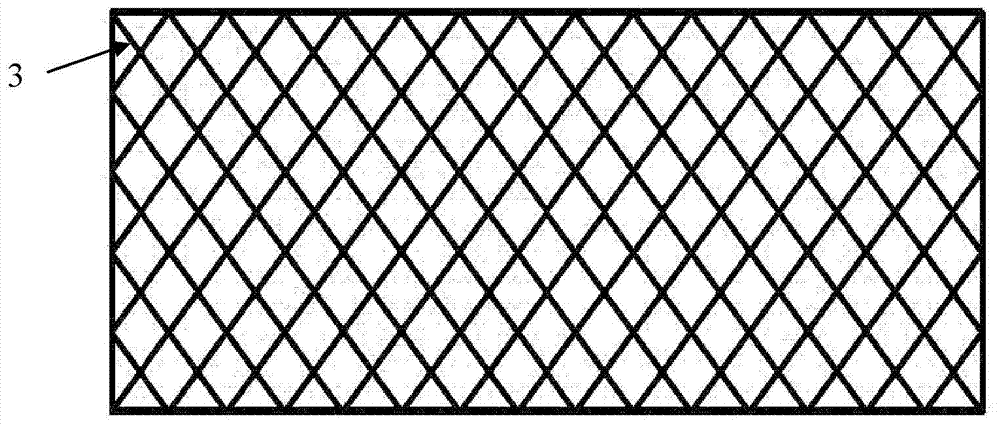

[0033] image 3 Shown is a plan view of a pipe support according to yet another embodiment of the present invention. The pipe support frame is made in the form of a single layer without coating, which is braided by composite wire. The composite wire 3 is formed by twisting two materials (A and B) together in a ratio of 1:3. Material A is a flexible metal wire , in this example a platinum-iridium alloy wire with a diameter of 0.0014 inches, and Material B is a biodegradable fiber filament, in this case polylactic acid (PLA), with a diameter of 0.0012 inches.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com