Self-decomposition cold sterilization technology for retaining freshness of fresh beer

A technology for fresh beer and cold sterilization, applied in the field of fresh beer preservation, can solve the problems of lowering product grades, damage to the taste and quality of fresh beer, etc., and achieves the effect of obvious effect and simple operation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

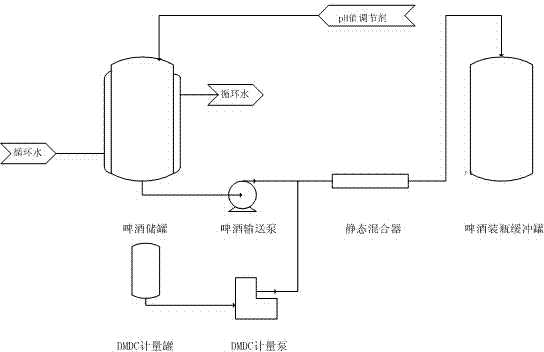

Method used

Image

Examples

Embodiment 1

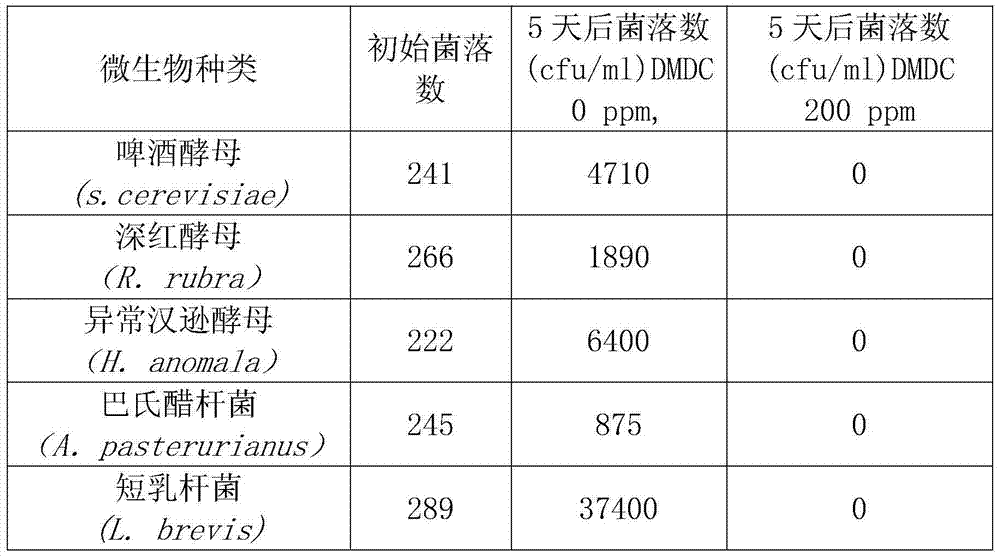

[0024] The fresh beer produced in Comparative Example 1 was sterilized in an autoclave at a temperature of 120 degrees for 30 minutes, and the pH value of the solution was adjusted to 4 with citric acid for use. In a sterile environment, place the strains to be tested into the test tube slants. Lactobacillus brevis and Acetobacter pasteuriani were cultured in a constant temperature incubator at 30 degrees for 36 hours, while Saccharomyces cerevisiae, Rhodotorula rubrum and Hansenula anomaly were cultured at a temperature of 25-28 degrees for 48 hours before use. Use an inoculation loop to pick up various bacterial bodies respectively in test tubes equipped with 9ml sterile saline, and mix them with a vortex mixer for 20 seconds. Count with a hemocytometer and adjust the bacterial concentration in the suspension to 10 5 cfu / ml. Use a quantitative pipette to draw 0.5ml of bacterial liquid and add it to 100ml of sterilized beer liquid. In the comparative sample, beer solutions...

Embodiment 2

[0028] The fresh beer produced in Comparative Example 1 was sterilized in an autoclave at a temperature of 120 degrees for 30 minutes, and the pH value of the solution was adjusted to 4 with citric acid for use. In a sterile environment, place the strains to be tested into the test tube slants. Lactobacillus brevis and Acetobacter pasteuriani were cultured in a constant temperature incubator at 30 degrees for 36 hours, while Saccharomyces cerevisiae, Rhodotorula rubrum and Hansenula anomaly were cultured at a temperature of 25-28 degrees for 48 hours before use. Use an inoculation loop to pick up various bacterial bodies respectively in test tubes equipped with 9ml sterile saline, and mix them with a vortex mixer for 20 seconds. Count with a hemocytometer and adjust the bacterial concentration in the suspension to 10 5 cfu / ml. Use a quantitative pipette to draw 0.5ml of bacterial liquid and add it to 100ml of sterilized beer liquid. In the comparative sample, beer solutions...

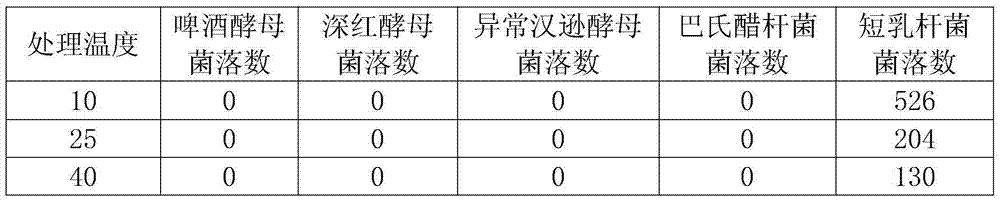

Embodiment 3

[0031] The fresh beer produced in Comparative Example 1 was sterilized with a temperature of 120 degrees for 30 minutes in an autoclave. In a sterile environment, place the strains to be tested into the test tube slants. Lactobacillus brevis and Acetobacter pasteuriani were cultured in a constant temperature incubator at 30 degrees for 36 hours, while Saccharomyces cerevisiae, Rhodotorula rubrum and Hansenula anomaly were cultured at a temperature of 25-28 degrees for 48 hours before use. Use an inoculation loop to pick up various bacterial bodies respectively in test tubes equipped with 9ml sterile saline, and mix them with a vortex mixer for 20 seconds. Count with a hemocytometer and adjust the bacterial concentration in the suspension to 10 5cfu / ml. Use a quantitative pipette to draw 0.5ml of bacterial liquid and add it to 100ml of sterilized beer liquid. In the comparative sample, the beer solutions of various strains were prepared in the same way. The pH value was adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com