Electrolytic copper foil surface treatment method

A technology of surface treatment and electrolytic copper foil, which is applied in the direction of metal material coating process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

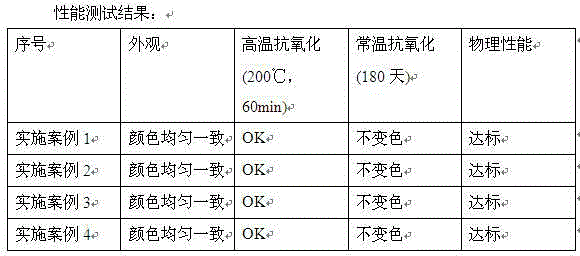

Examples

Embodiment example 1

[0022] The traditional post-processing machine processes 9 micron double-sided photoelectrolytic copper foil, and the passivation solution component is Zn 2+ 50 g / L, Ni 2+ 5.0g / L; sodium dihydrogen phosphate 1.0g / L; 1-phenyl-5-mercaptotetrazolium (PMTA) 3.0g / L; sodium citrate 60 g / L; pH value: 3.5~5.5, current density 0.5A / dm 2 ; Processing copper foil line speed 30m / min.

Embodiment example 2

[0024] The one-piece machine processes 9 micron double-sided photoelectrolytic copper foil, and the passivation solution component is Zn 2+ 30 g / L, Ni 2+ 3.0g / L; sodium dihydrogen phosphate 1.0g / L; 1-phenyl-5-mercaptotetrazolium (PMTA) 2.0g / L; sodium citrate 60 g / L; pH value: 3.5~5.5, current density 0.3 A / dm 2 ; Processing copper foil line speed 6.0m / min.

Embodiment example 3

[0026] One-piece machine processing ultra-thin 7 micron double-sided photoelectrolytic copper foil, the passivation solution component is Zn 2+ 30 g / L, Ni 2+ 3.0g / L; sodium dihydrogen phosphate 1.0g / L; 1-phenyl-5-mercaptotetrazolium (PMTA) 2.0g / L; sodium citrate 60 g / L; pH value: 3.5~5.5, current density 0.3 A / dm 2 ; Processing copper foil line speed 6.8m / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com