Method for improving spin-orbit coupling strength of Co/Pt thin film material

A technology of rail coupling and thin-film materials, which is applied in metal material coating process, ion implantation plating, coating, etc., can solve the problems of volatility and limit the application of low-power logic storage devices, so as to increase the coupling strength, Low cost and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

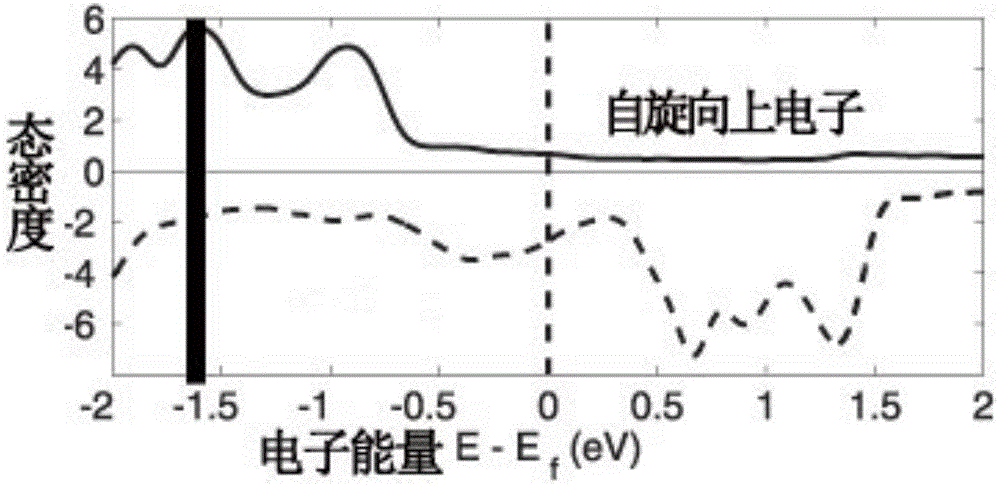

[0018] figure 1 The preparation conditions of the samples are as follows: first, the TiNi shape memory alloy without pre-stretching and surface argon ion treatment is subjected to surface polishing treatment: mechanical polishing and chemical polishing, and the surface roughness after polishing is 2 nm; then, using acetone and The surface was cleaned with alcohol to obtain a TiNi substrate with a clean surface, and the thickness of the substrate was 0.1 mm. Then, using the magnetron sputtering method, on the above-mentioned TiNi memory alloy substrate, Co atoms (with a thickness of ) and Pt atoms (thickness of ), the number of repetitions is 5, thereby preparing the deposition Multilayer film with a background vacuum of 1×10 before sputter deposition -5 Pa, the argon pressure during sputtering is 0.5Pa.

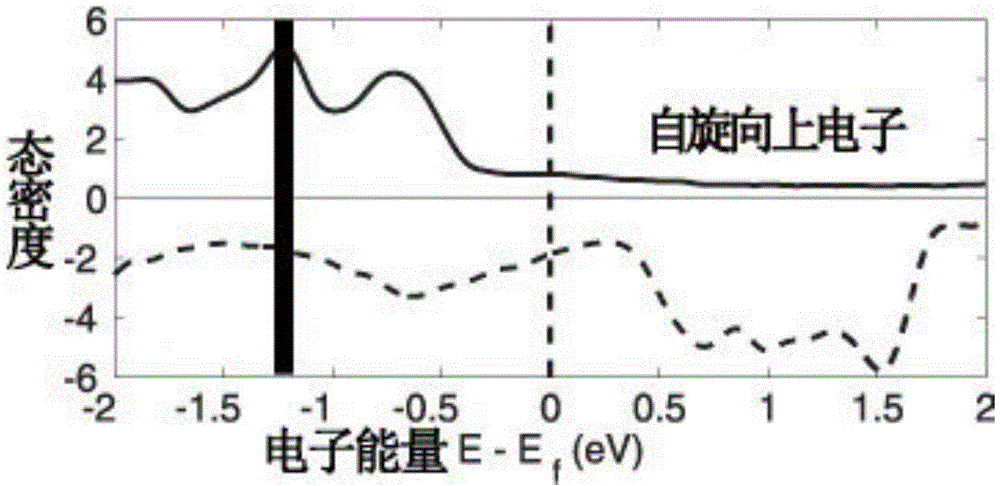

[0019] figure 2 The preparation conditions of the samples are as follows: first, the TiNi memory alloy substrate is subjected to pre-stretching, surface polishing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com