Water-soluble PEDOT-PSS dispersion and homogeneous polymerization preparation method thereof

A PEDOT-PSS, homogeneous polymerization technology, applied in the field of homogeneous polymerization preparation of water-soluble PEDOT-PSS dispersion, can solve problems such as difficulty in dispersing a large amount of EDOT, PEDOT-PSS film surface roughness, disadvantage, etc., to achieve excellent dispersion excellent film-forming properties, low haze effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] a) Preparation of polystyrene sulfonic acid solution: Weigh 126g of a mixed solvent composed of dimethyl sulfoxide and deionized water, add 2.8g of sodium polystyrene sulfonate with a weight average molecular weight of 500,000, and stir to fully dissolve it , Form a transparent solution, add 1.2mL hydrochloric acid (mass fraction is 36%) again, make the pH value of reaction solution be 1.6, obtain the polystyrene sulfonic acid solution that mass concentration is 1.9%; Dimethyl sulfoxide and The molar ratio of deionized water is 1:11;

[0044] b) Add EDOT monomer: add 1g of EDOT monomer to the polystyrene sulfonic acid solution prepared in step a), and stir fully to obtain polystyrene sulfonic acid and EDOT transparent solution with a molar concentration of 0.06mol / L of EDOT monomer ;

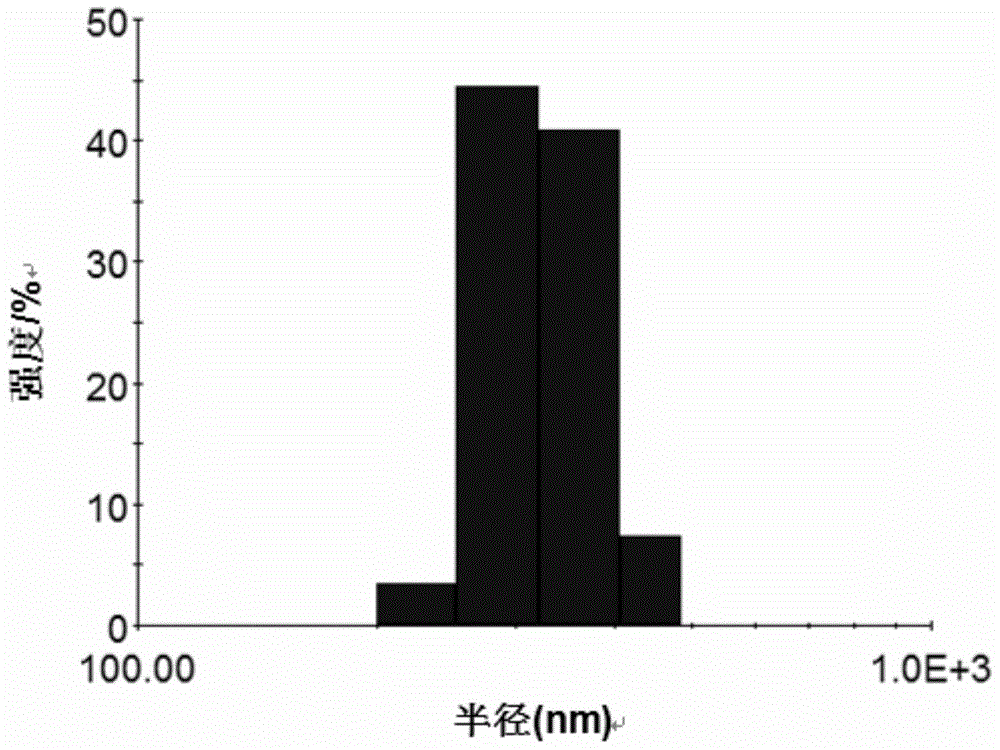

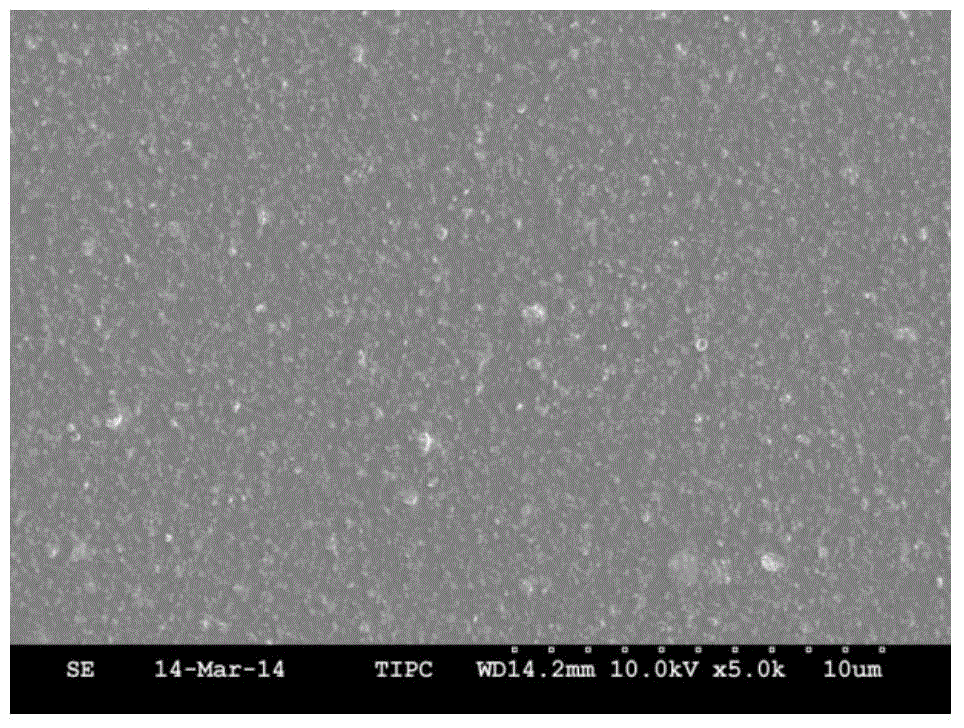

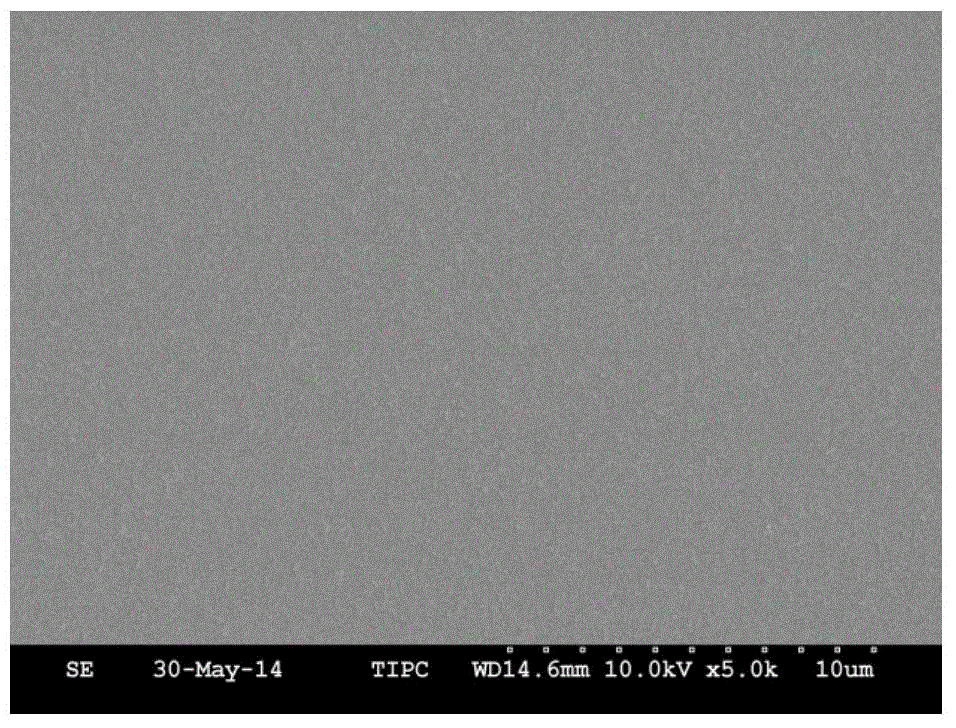

[0045] c) Adding an oxidant: under constant stirring, add 2.01 g of sodium persulfate to the polystyrene sulfonic acid and EDOT transparent solution formed in step b), to obtain a transp...

Embodiment 2

[0049] a) Preparation of polystyrene sulfonic acid solution: Weigh 116 g of acetonitrile and deionized water mixed solvent, add 5.6 g of sodium polystyrene sulfonate with a weight average molecular weight of 350,000, stir to fully dissolve it, and form a transparent solution , add 1.8mL hydrochloric acid (mass fraction is 36%) again, make the pH value of reaction solution be 1.5, obtain mass concentration and be the polystyrene sulfonic acid solution of 4.1%; The mol ratio of acetonitrile and deionized water in the mixed solvent is 1 :8;

[0050] b) Add EDOT monomer: 1.8g EDOT monomer is added to the polystyrene sulfonic acid solution prepared in step a), and fully stirred to obtain polystyrene sulfonic acid with a molar concentration of EDOT monomer of 0.108mol / L, EDOT transparent solution;

[0051] c) Adding an oxidizing agent: under constant stirring, add 4.02 g of sodium persulfate to the polystyrenesulfonic acid / EDOT transparent solution formed in step b) to obtain a tra...

Embodiment 3

[0055] a) Preparation of polystyrene sulfonic acid solution: Weigh 120g of a mixed solvent composed of dimethyl sulfoxide, acetonitrile and deionized water, add 4.2g of sodium polystyrene sulfonate with a weight average molecular weight of 1,000,000, and stir to make it Dissolve fully, form transparent solution, then add 1.6mL hydrobromic acid (mass fraction is 39%), make the pH value of reaction solution be 1.6, obtain the polystyrene sulfonic acid solution that mass concentration is 3.0%; The molar ratio of sulfoxide, acetonitrile, and deionized water is 1:1.4:22;

[0056] b) Add EDOT monomer: Add 1.5g EDOT monomer to the polystyrene sulfonic acid solution prepared in step a), stir well to obtain polystyrene sulfonic acid / EDOT transparent polystyrene sulfonic acid / EDOT with EDOT monomer molar concentration of 0.09mol / L mixture;

[0057] c) Adding an oxidizing agent: under continuous stirring, add 3.02 g of sodium persulfate into the polystyrenesulfonic acid / EDOT transparent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com