Cationic water-based fluoropolymer emulsion and preparation method thereof

A polymer emulsion, cationic technology, applied in the field of cationic water-based fluoropolymer emulsion and its preparation, can solve the problems of no flocculation ability, inability to eliminate static electricity, inability to achieve low pollution, antibacterial, antistatic and flocculation, etc. Avoid the effects of easy migration, improved water resistance, and safe product use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

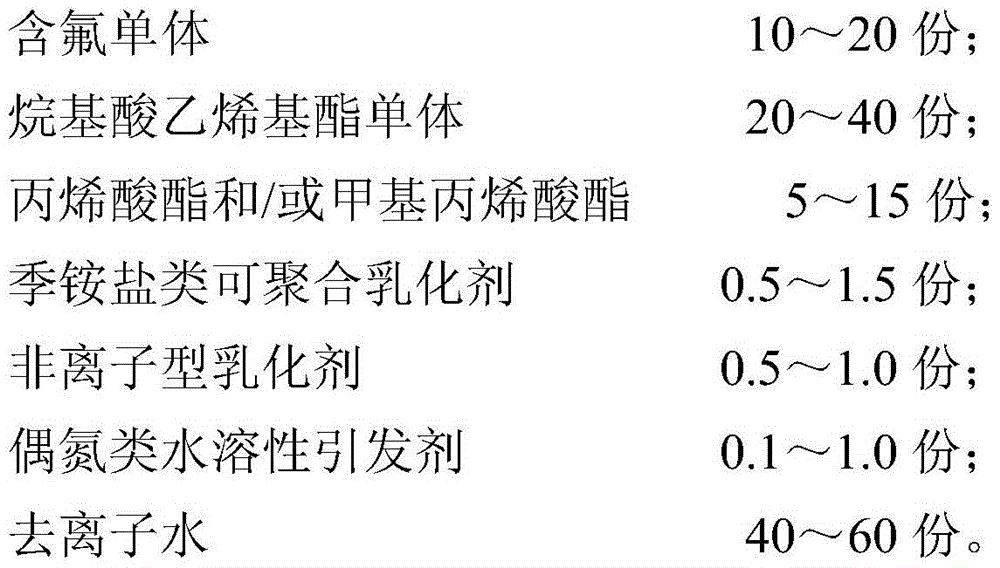

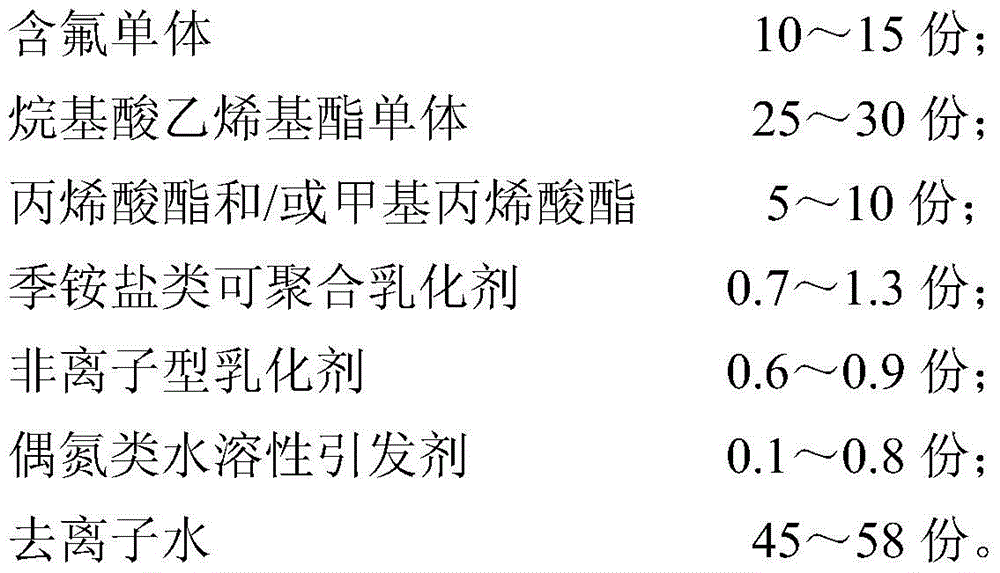

Method used

Image

Examples

Embodiment 1

[0027] Vinyl acetate 142.07g, vinyl tertiary carbonate 46.90g, butyl acrylate 46.95g, nonylphenol polyoxyethylene (n=10) maleate diester ethyltrimethylammonium chloride 5.32g, Put 4.06 g of styrylphenol polyoxyethylene ether and 136.14 g of deionized water into a container, and disperse and emulsify for 20 to 30 minutes to prepare a pre-emulsified monomer liquid.

[0028] 1.68 g of 2,2'-azobis(2-methylpropylamidine) dihydrochloride (AIBA) aqueous solution was added to 89.30 g of deionized water to prepare an aqueous initiator solution.

[0029] Take 10% emulsified monomer solution, 20% initiator aqueous solution, nonylphenol polyoxyethylene (n=10) maleic acid diester ethyltrimethylammonium chloride 1.63g, styrylphenol polyoxyethylene Add 1.25g of ether and 190.46g of deionized water into the reaction kettle with mechanical stirring, thermocouple, heating and cooling pipes, vacuumize, fill with nitrogen, and after vacuuming and repeating 3 times, add 96g of chlorotrifluoroethyl...

Embodiment 2

[0031] Vinyl acetate 189.28g, butyl acrylate 47.21g, dodecylpolyoxyethylene (n=10) maleic acid diester ethyltrimethylammonium chloride 5.31g, styrylphenol polyoxyethylene 4.06 g of base ether and 104.18 g of deionized water were put into a container and emulsified by a high-shear emulsifier for 20 to 30 minutes to prepare a pre-emulsified monomer liquid.

[0032] 1.68 g of 2,2'-azobis(2-methylpropylamidine) dihydrochloride (AIBA) aqueous solution was added to 89.30 g of deionized water to prepare an aqueous initiator solution.

[0033] Get 8% emulsified monomer solution, 20% initiator aqueous solution, dodecyl polyoxyethylene group (n=10) ethylmaleic acid diester trimethylammonium chloride 1.64g, styrylphenol polyoxyethylene Add 1.25g of base ether and 190.68g of deionized water into a reaction kettle with a mechanical stirring device, a thermocouple, a heating device and a cooling pipe, vacuumize, fill with nitrogen, and after vacuumizing and repeating 3 times, add trifluoro ...

Embodiment 3

[0035] 140.65g of vinyl acetate, 47.26g of vinyl tert-carbonate, 47.65g of butyl acrylate, 5.22g of octadecyl polyoxyethylene (n=20) maleic acid diester ethyl trimethyl ammonium chloride , 4.08 g of fatty alcohol polyoxyethylene ether, and 104.41 g of deionized water were put into a container to disperse and emulsify for 20 to 30 minutes to prepare a pre-emulsified monomer liquid.

[0036] 1.40 g of 2,2'-azobis(2-methylpropylamidine) dihydrochloride (AIBA) was added to 74.47 g of deionized water to prepare an aqueous initiator solution.

[0037]Get 15% emulsified monomer solution, 20% initiator aqueous solution, stearyl polyoxyethylene (n=20) maleic acid diester ethyl trimethyl ammonium chloride 1.54g, nonylphenol polyoxyethylene Add 1.21g of ether and 189.45g of deionized water into the reaction kettle with mechanical stirring, thermocouple, heating and cooling pipes, vacuumize, fill with nitrogen, and after vacuumizing and repeating 3 times, add 76g of chlorotrifluoroethylen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gel rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com