System and method for producing biogas from perishable waste by two-phase pressurized anaerobic fermentation

An anaerobic fermentation and waste technology, applied in fermentation, waste fuel, gas production bioreactor, etc., can solve the problems of low reaction load, low methane content, and inability to achieve continuous use of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

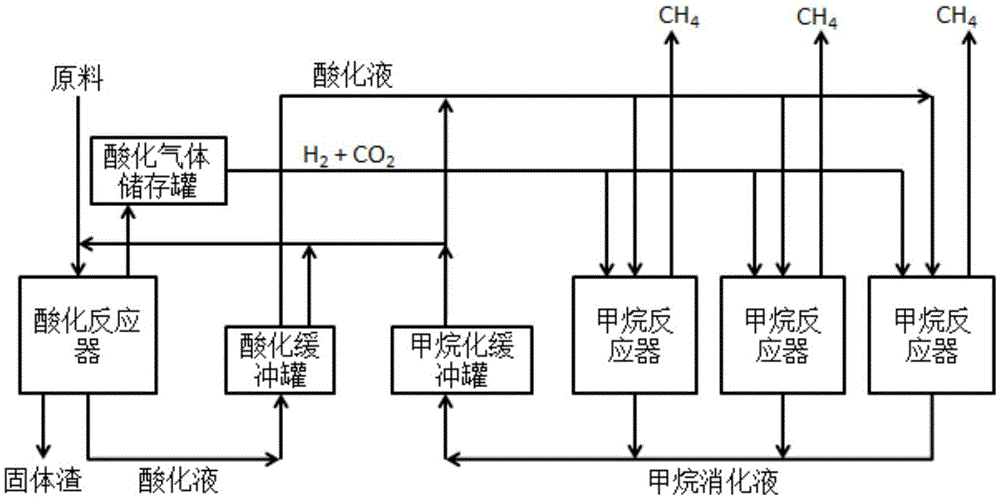

[0063] This embodiment provides a two-phase pressurized anaerobic fermentation system for producing biogas from perishable wastes, the flow chart of which is as follows figure 1 As shown, the system includes: acidification reactor, acidification gas storage tank, acidification buffer tank, three methanation reactors, methanation buffer tank;

[0064] The acidification reactor is equipped with an inlet, a gas outlet, a liquid outlet and a solid outlet;

[0065] The methanation reactor is provided with a gas inlet, a liquid inlet, a gas outlet and a liquid outlet;

[0066] The inlet of the acidification gas storage tank is connected with the gas outlet of the acidification reactor through pipelines; the outlet of the acidification gas storage tank is respectively connected with the gas inlets of the three methanation reactors;

[0067] The inlet of the acidification buffer tank is connected with the liquid outlet of the acidification reactor through a pipeline; , the second me...

Embodiment 2

[0073] This embodiment provides a method for two-phase pressurized anaerobic fermentation to treat perishable wastes to produce biogas, which is realized by using the system in Embodiment 1, and the method includes the following steps:

[0074] Put the perishable wastes obtained after sorting and crushing into the acidification reactor, the reactor type is complete mixed type (CSTR), add the fermentation liquid of the running biogas plant as the inoculum, and carry out the acidification reaction to obtain acidification gas and acidification liquid; after the long-term operation of the reaction, large particle residues will be accumulated, which can be discharged through the solid outlet of the acidification reactor; the residues will be reused after solid-liquid separation.

[0075] The organic loading rate of the above acidification reaction is 10kgVS / m 3 / d, the hydraulic retention time is 4 days, the pH value is 4-6, and the reaction temperature is 37°C;

[0076] Add the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com