A method for anaerobic fermentation of cadmium-containing biomass

An anaerobic fermentation and biomass technology, applied in fermentation, biological sludge treatment, anaerobic digestion treatment and other directions, can solve problems such as unreported, achieve the effect of avoiding excessive acidification, improving stability and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

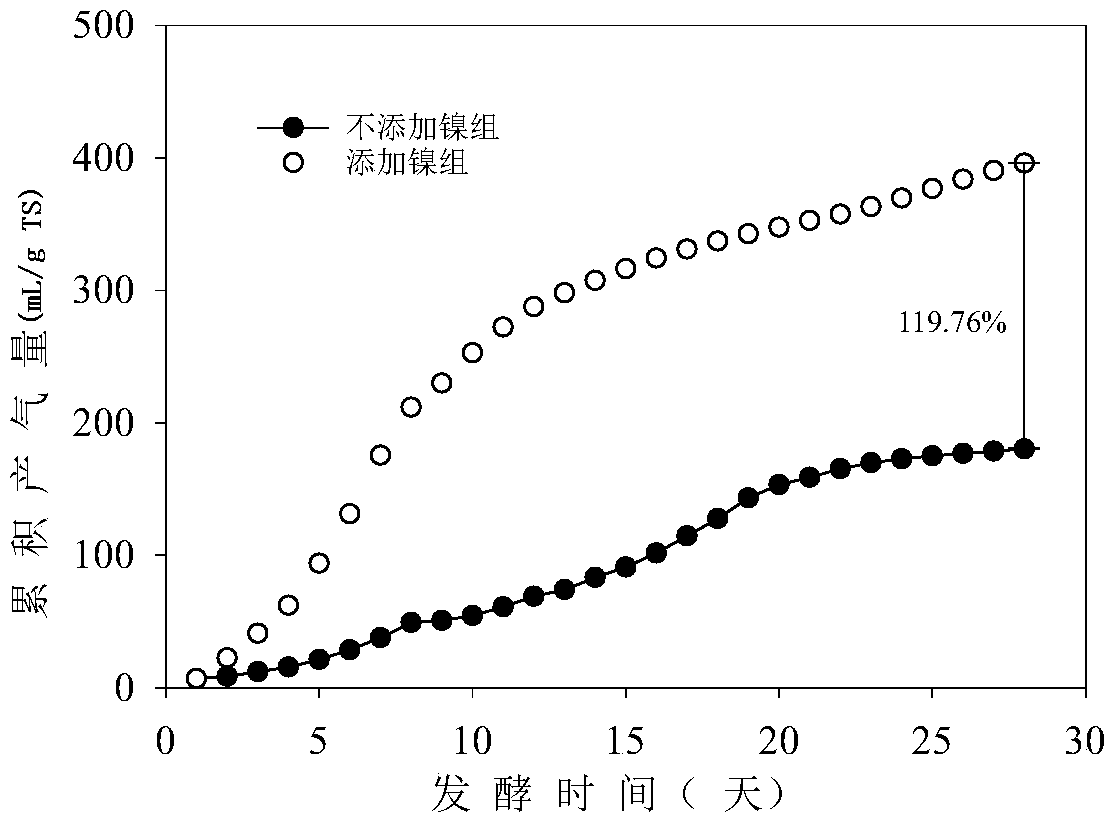

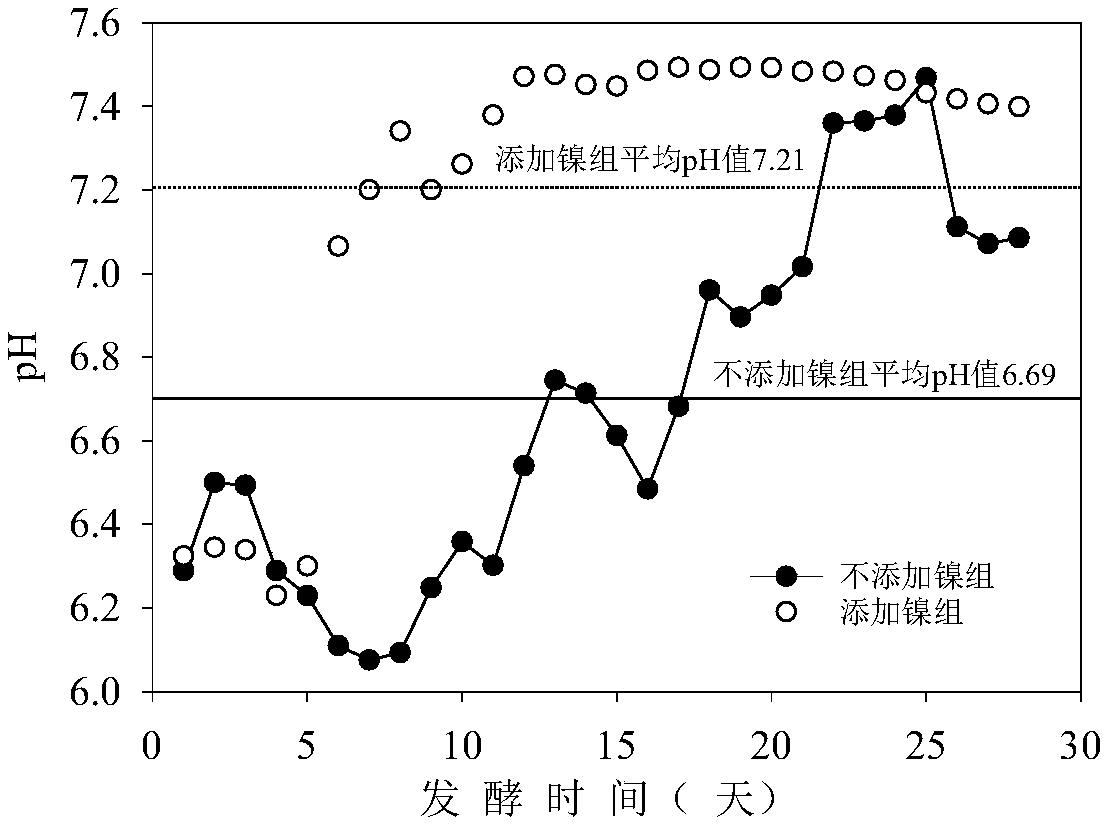

Embodiment 1

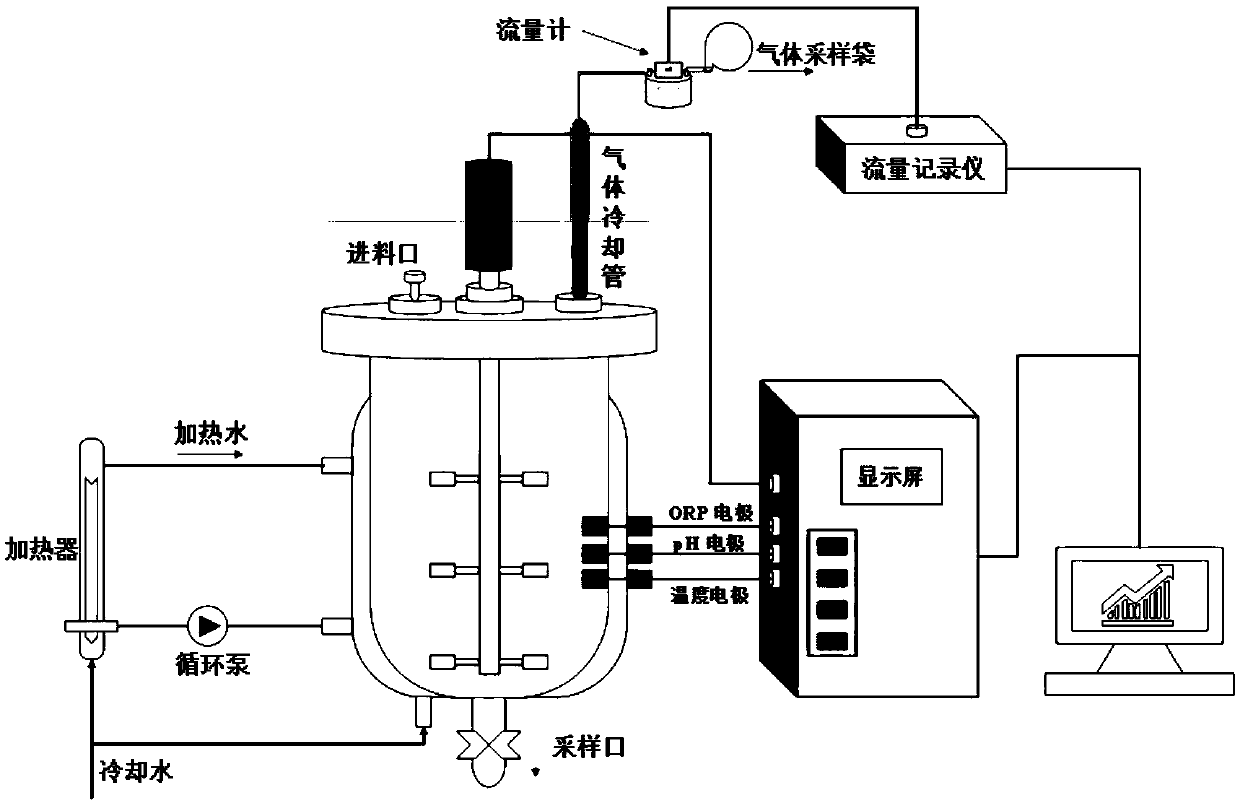

[0024] Such as image 3 The shown anaerobic fermentation experimental device adopts an automatic stirring stainless steel fermentation system, the total volume of the tank is 30L, and the working volume is 20L. The specific steps of anaerobic fermentation include:

[0025] (1) High-temperature steam sterilization of the fermentation tank: empty the moisture in the insulation layer of the fermentation tank, connect the steam generator, use the steam generator to provide steam, heat the insulation layer, adjust the steam entry and removal speed, and increase the temperature in the fermentation tank Keep at 121°C for 30 minutes, then close the steam generator and the inlet and outlet valves to complete the sterilization.

[0026] (2) Add feed liquid into the fermentation tank through the feed port, the total solid concentration of the feed liquid is 8% (the total solid concentration is the dry weight of fermentation raw materials / (dry weight of fermentation raw materials+water we...

Embodiment 2

[0036] A method for preparing biogas by anaerobic fermentation of cadmium-containing biomass, comprising the steps of:

[0037] (1) The fermenter is sterilized by high-temperature steam, and the steps are the same as in Example 1.

[0038] (2) Add fermented raw materials, deionized water and nickel (as NiCl 2 ·6H 2 (2 added) feed liquid formulated, the total solid concentration of feed liquid is 8% (total solid concentration is fermentation raw material dry weight / (fermentation raw material dry weight+water weight)), stir evenly and place 2h, make fermentation broth system stable ; The fermentation raw material includes cadmium-containing biomass and cow dung, and the dry matter mass ratio of the two is 1:1;

[0039] (3) Fill the fermenter with nitrogen (N 2 ) for 5 minutes to expel the air in the fermenter, then immediately close the feed inlet, carry out anaerobic fermentation at 55.0°C, and collect the generated gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com