A kind of production method of instant fermented celery soft can with long shelf life

A production method and shelf life technology, applied in the direction of preserving fruits/vegetables with acid, preserving fruits/vegetables through radiation/electrical treatment, etc., can solve the problems of post-acidification of products, difficulty in controlling the acidity of fermented vegetables, and short shelf life. Achieve short time, good color protection effect, and prevent excessive acidification of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) After removing the leaves of fresh celery, rinse with water, drain and put into 1.8wt% salt, 0.5% calcium lactate, 3.8wt% concentrated pear juice (65~70°Bx of sugar content), 13mg / kg zinc lactate In the water-sealed fermentation container of the aqueous solution, inoculate 5% v / v Lactobacillus fermentum FM-P13 (CGMCC No.8611), ferment at 32 ℃, when the pH value of the solution reaches 3.8, add 0.11g / kg Streptococcus lactis Su (Zhejiang Xinyinxiang Biological Engineering Co., Ltd.) terminated the fermentation.

[0027] (2) Take out the fermented celery, bag it, and vacuum seal it.

[0028] (3) The fermented celery of vacuum packaging is put into pulse microwave equipment (Rui Ning Magnetoelectric Technology Application Research Institute, Xiaguan District, Nanjing City), and is sterilized. During pulse microwave equipment processing, the instantaneous output power is 360kw, and the output pulse width is 5 μ s, The duty ratio is 1:1100, and the whole process lasts fo...

Embodiment 2

[0031] (1) After removing the leaves of fresh celery, rinse with water, drain and put into 2.4wt% salt, 0.5% calcium lactate, 4.6wt% concentrated pear juice (sugar content 65~70°Bx), 16mg / kg zinc lactate In the water-sealed fermentation vessel of the aqueous solution, inoculate 3% v / v Lactobacillus fermentum FM-P13 (CGMCC No.8611), ferment at 30°C, when the pH value of the solution reaches 3.8, add 0.09g / kg Streptococcus lactis Su (Zhejiang Xinyinxiang Biological Engineering Co., Ltd.) terminated the fermentation.

[0032] (2) Take out the fermented celery, bag it, and vacuum seal it.

[0033] (3) The fermented celery of vacuum packaging is put into pulse microwave equipment (Rui Ning Magnetoelectric Technology Application Research Institute, Xiaguan District, Nanjing City), and is sterilized. During pulse microwave equipment processing, the instantaneous output power is 380kw, and the output pulse width is 6 μ s, The duty ratio is 1:1000, and the whole process lasts for 4 mi...

Embodiment 3

[0036] 1. Determination of the growth curve of strain FM-P13.

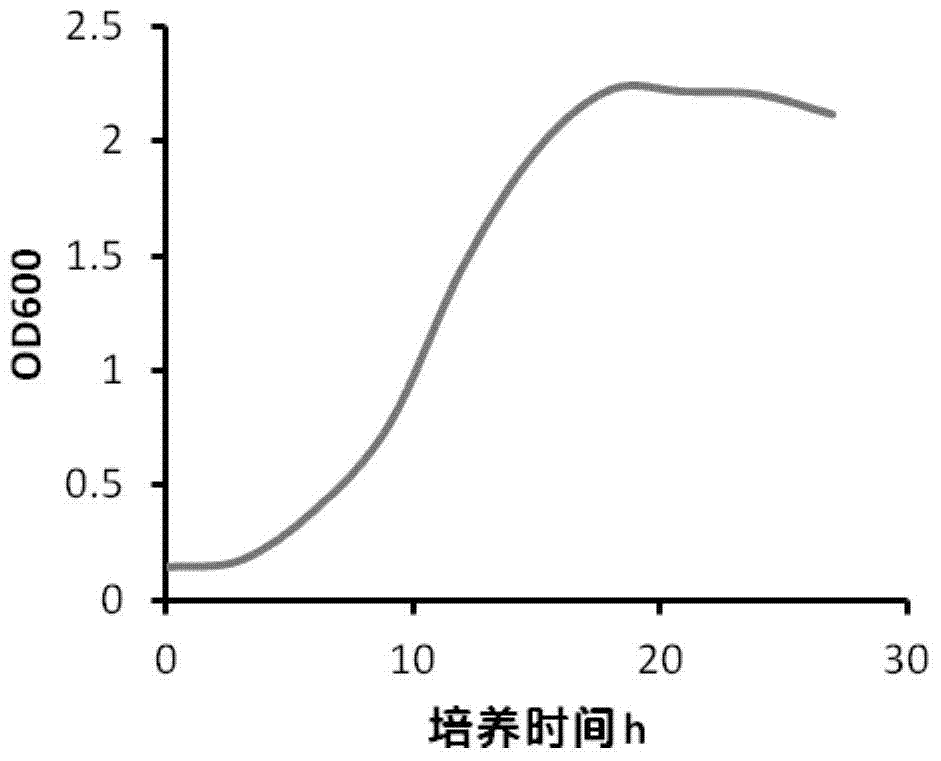

[0037] The FM-P13 strains were inoculated into 5ml MRS liquid medium with an inoculation amount of 2% v / v, cultured statically at 35°C, and incubated at 0, 3, 6, 9, 12, 15, 18, 21, 24 , 27h to measure the OD600 value, the experiment was repeated 3 times, the results are shown in figure 1 , it can be seen from the figure that the strain reaches a stable period after 18 hours of growth. It can be seen that FM-P13 grows faster and has better fermentation ability.

[0038] 2. Determination of the optimum growth temperature of strain FM-P13.

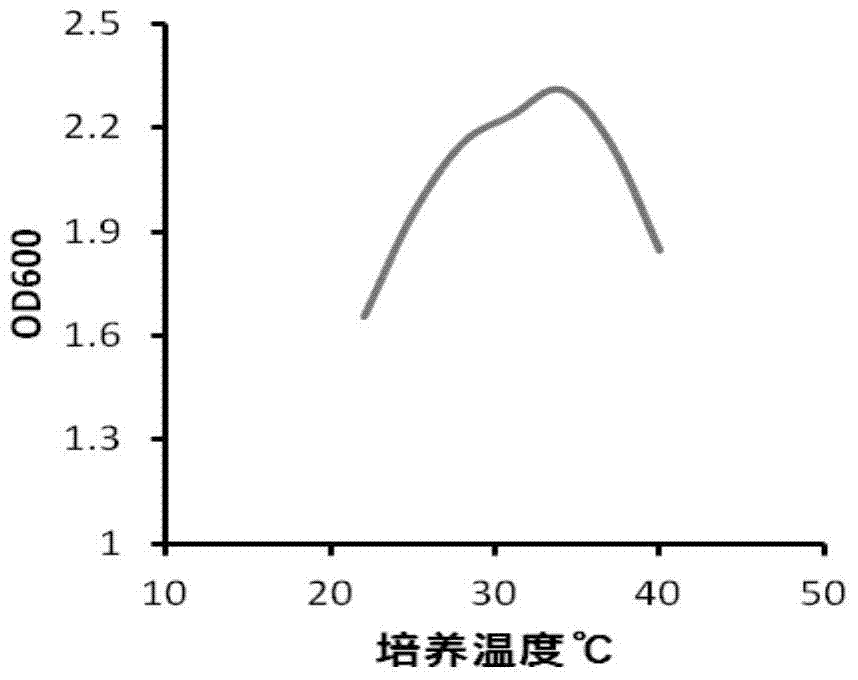

[0039] The strains of FM-P13 were inoculated into 5ml of MRS liquid medium with an inoculation amount of 2% v / v, cultured statically at 22, 25, 28, 31, 34, 37, and 40°C for 18 hours, and the OD600 was measured respectively. Repeat 3 times. see results figure 2 , it can be seen from the figure that with the increase of culture temperature, the OD600 of FM-P13 showed a trend o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com