Energetic polyoxide compound super-thermite and preparation method thereof

A technology of super thermite and polyoxide, applied in the direction of explosives, etc., can solve the problems of nano-aluminum powder incompatibility, high reactivity, easy agglomeration surface, etc., and achieve the effect of easy reaction process, high purity and high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

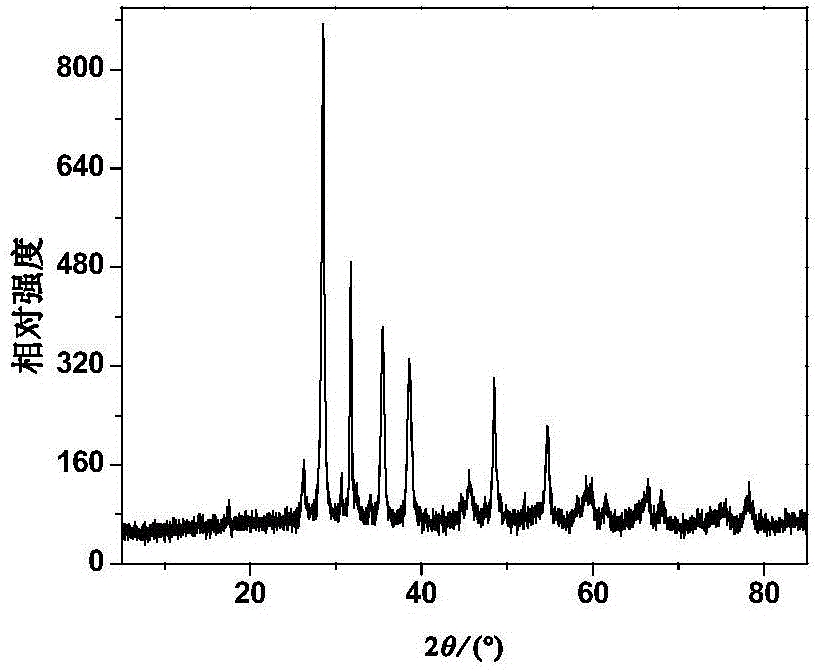

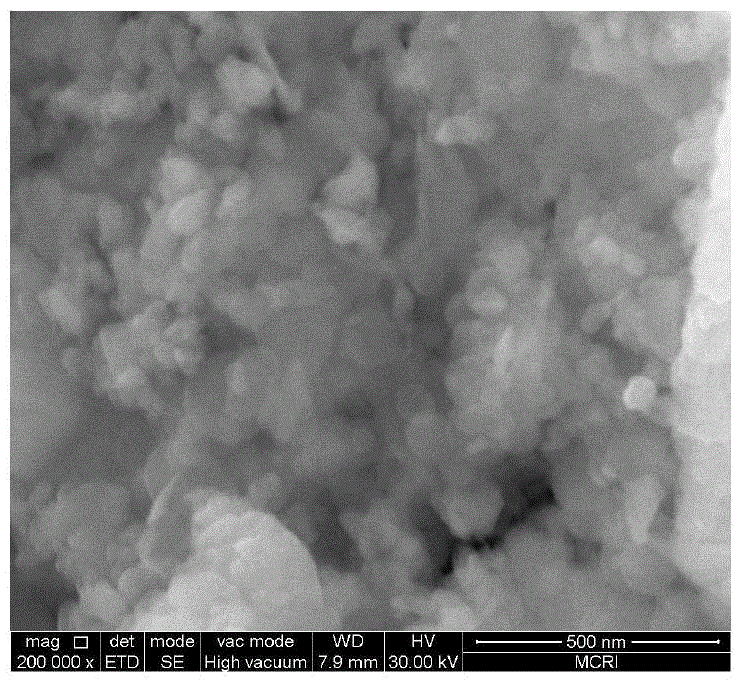

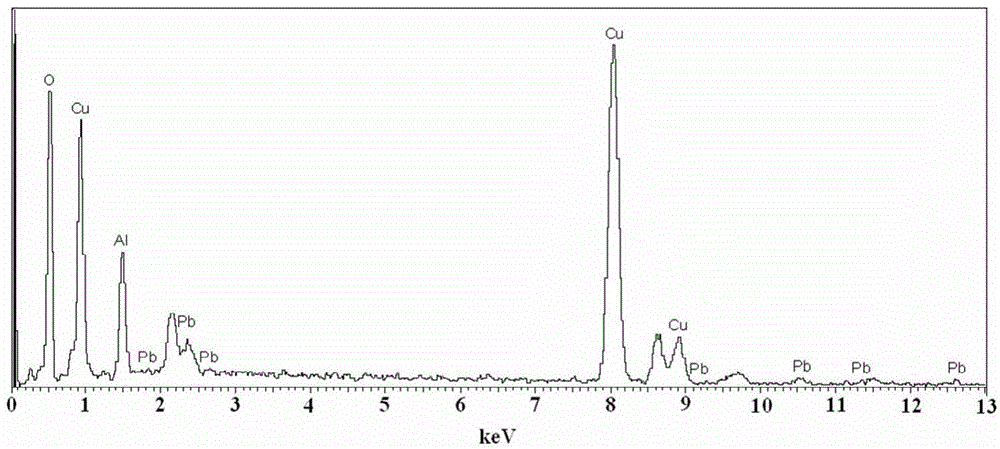

[0035] Example 1 Al / PbO·CuO

[0036] (1) At room temperature, weigh PbNO respectively according to the molar ratio of 1:1:4 3 , Cu(NO 3 ) 2 ·3H 2 O and NaOH, first PbNO 3 and Cu(NO 3 ) 2 ·3H 2 O mixing, adding Tween-80 of 1% of the total mass as a dispersant, mixing and grinding;

[0037] (2) Add the finely ground NaOH to the mixture, and grind it thoroughly for 40 minutes at room temperature to complete the solid phase reaction; the product is washed with distilled water, absolute ethanol and ultrasonic waves several times, and dried in a vacuum drying oven at 80°C for 3 hours after suction filtration , that is, nanocomposite metal oxide PbO·CuO;

[0038] (3) Weigh 0.80g of nano-Al and 6.75g of composite PbO·CuO, and disperse them in reaction vessels containing 37.04mL and 37.13mL of n-hexane respectively under ultrasonic conditions; subsequently, the dispersed nano-Al and PbO·CuO Place CuO in the same reaction vessel, and continue ultrasonic dispersion at a constant...

Embodiment 2

[0045] Embodiment 2Al / Fe 2 o 3 · Bi 2 o 3

[0046] (1) At room temperature, weigh Fe(NO 3 ) 3 9H 2 O, Bi(NO 3 ) 3 ·5H 2 O and NaOH, Fe(NO 3 ) 3 9H 2 O and Bi(NO 3 ) 3 ·5H 2 O mixing, adding Tween-80 of 1% of the total mass as a dispersant, fully mixing and carefully grinding;

[0047] (2) Add the finely ground NaOH into the mixture, and grind it sufficiently at room temperature for 35 minutes to complete the solid-phase reaction; the product is washed with distilled water, absolute ethanol and ultrasonic waves several times, and dried in a vacuum drying oven at 80°C for 4 hours after suction filtration , that is, the nanocomposite metal oxide Fe 2 o 3 · Bi 2 o 3 ;

[0048] (3) Weigh 0.90g nano-Al and 5.20g composite Fe 2 o 3 · Bi 2 o 3 , were dispersed in the reaction vessel containing 41.67mL and 13.84mL of n-hexane under ultrasonic conditions; subsequently, the dispersed nano-Al and SnO 2 Place CuO in the same reaction vessel, and continue ultrasonic...

Embodiment 3

[0055] Example 3Al / Bi 2 o 3 ·CuO

[0056] (1) At room temperature, weigh the Bi(NO 3 ) 3 ·5H 2 O, Cu(NO 3 ) 2 ·3H 2 O and NaOH, Bi(NO 3 ) 3 ·5H 2 O and Cu(NO 3 ) 2 ·3H 2 O mixing, adding Tween-80 of 1% of the total mass as a dispersant, fully mixing and carefully grinding;

[0057] (2) Add the finely ground NaOH to the mixture, and grind it thoroughly for 40 minutes at room temperature to complete the solid phase reaction; the product is washed with distilled water, absolute ethanol and ultrasonic waves several times, and dried in a vacuum drying oven at 85°C for 3 hours after suction filtration , that is, the nanocomposite metal oxide Bi 2 o 3 CuO;

[0058] (3) Weigh 0.57g nano-Al and 5.60g composite Bi 2 o 3 ·CuO was dispersed in reaction vessels containing 26.39mL and 17.09mL of n-hexane respectively under ultrasonic conditions; subsequently, the dispersed nano-Al and Bi 2 o 3 Place CuO in the same reaction vessel, and continue ultrasonic dispersion at a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com