Phosphogypsum based high flow state grouting material

A grouting material and high fluidity technology, applied in the field of building materials, can solve the problems of low flexural strength, poor water resistance, poor construction performance, etc., to improve water resistance and durability, reduce costs, and realize resource utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

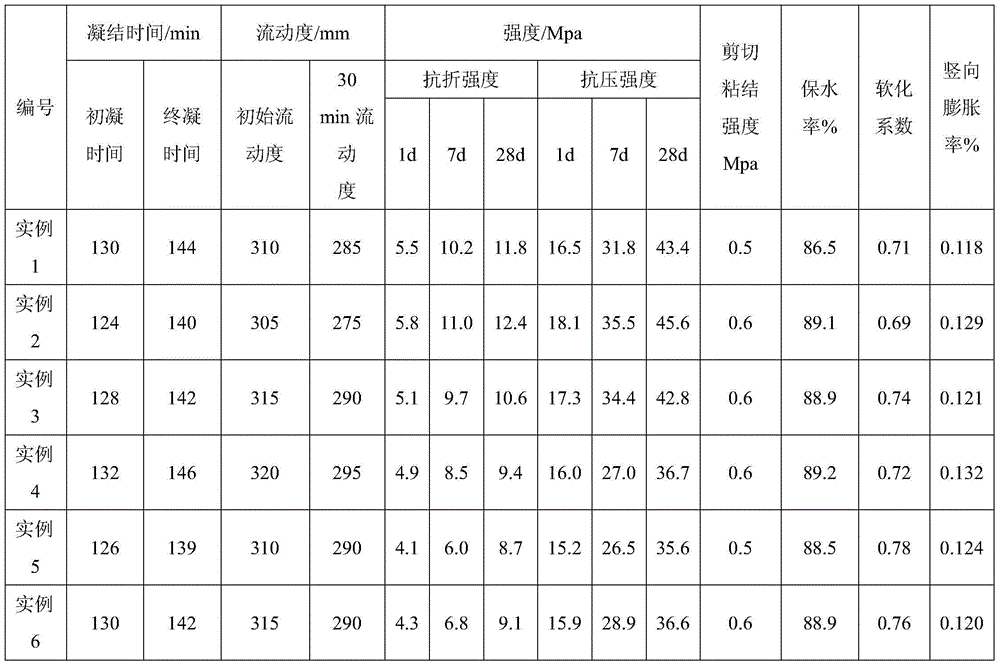

Embodiment 1

[0037] Weigh 220g (54 parts) of phosphorus-based high-strength gypsum, 150g (30 parts) of secondary fly ash, 20g (4 parts) of carbide slag, 25g (5 parts) of ordinary Portland cement, 35g (7 parts) of dihydrate gypsum whiskers parts), protein retarder 0.5g (0.1 parts), polycarboxylate superplasticizer 1.5g (0.3 parts), hydroxypropyl methylcellulose ether 0.4g (0.08 parts), silicone water repellent 0.25 g (0.05 parts), put it into a homogenizer and mix evenly, mix the obtained powder with 180g water (the ratio of water to material is 0.36:1), and stir evenly through a slurry mixer to obtain a phosphogypsum-based high-flow grouting material.

Embodiment 2

[0039]Weigh 300g (60 parts) of phosphorus-based high-strength gypsum, 130g (26 parts) of primary fly ash, 20g (4 parts) of carbide slag, 20g (4 parts) of sulphoaluminate cement, 30g (6 parts) of dihydrate gypsum whiskers parts), sodium citrate and protein retarder mixture 0.75g (0.15 parts), melamine-based water reducer 2.0g (0.4 parts), carboxymethyl cellulose ether and starch ether mixture 0.4g (0.08 parts), 0.25g (0.05 parts) of silicone water repellent, put into a homogenizer and mix evenly, mix the obtained powder with 190g water (water-material ratio is 0.38:1), and stir evenly through a slurry mixer to obtain a phosphogypsum-based High fluidity grouting material.

Embodiment 3

[0041] Weigh 240g (48 parts) of phosphorus-based high-strength gypsum, 170g (34 parts) of secondary fly ash, 25g (5 parts) of carbide slag, 25g (5 parts) of slag cement, 40g (8 parts) of dihydrate gypsum whiskers, 0.25g (0.05 parts) of the mixture of citric acid and protein retarder, 2.5g (0.5 parts) of naphthalene-based superplasticizer, 0.4g (0.08 parts) of the mixture of hydroxypropyl methylcellulose ether and starch ether, silicone Water-repellent 0.25g (0.05 part), put into the homogenizer and mix evenly, mix the obtained powder with 175g water (water-material ratio is 0.37:1), stir evenly through the slurry mixer, get phosphogypsum-based high flow grouting material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coagulation time | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com