A kind of cobalt-based transition metal oxygen reduction catalyst and its preparation method and application

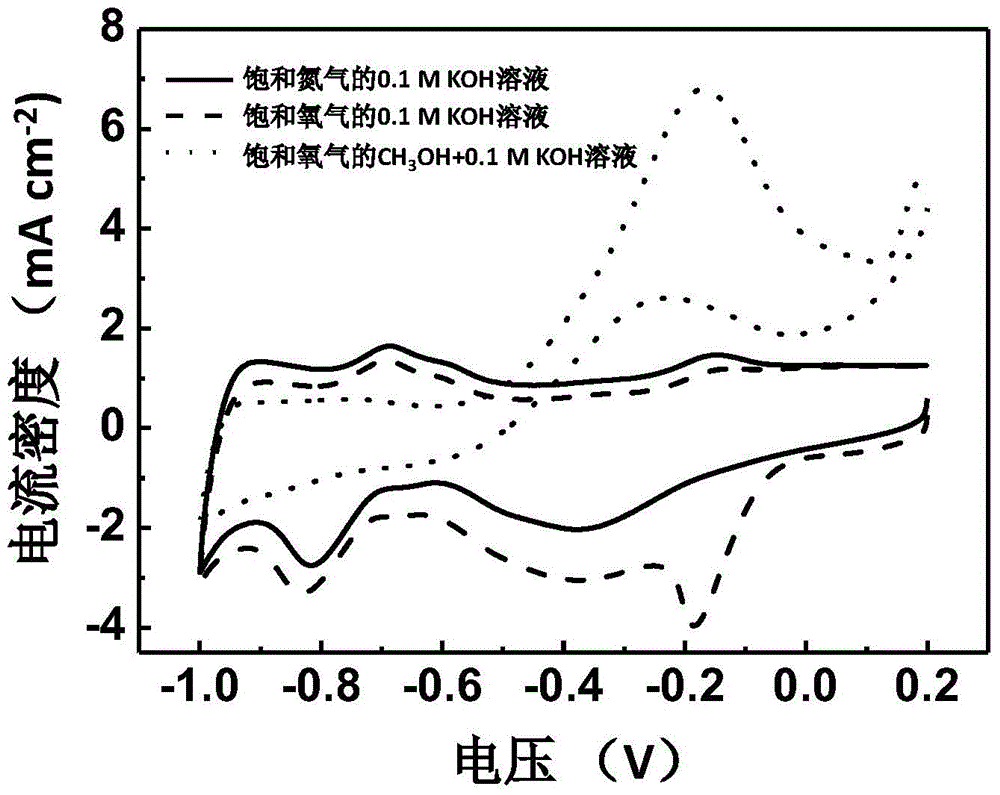

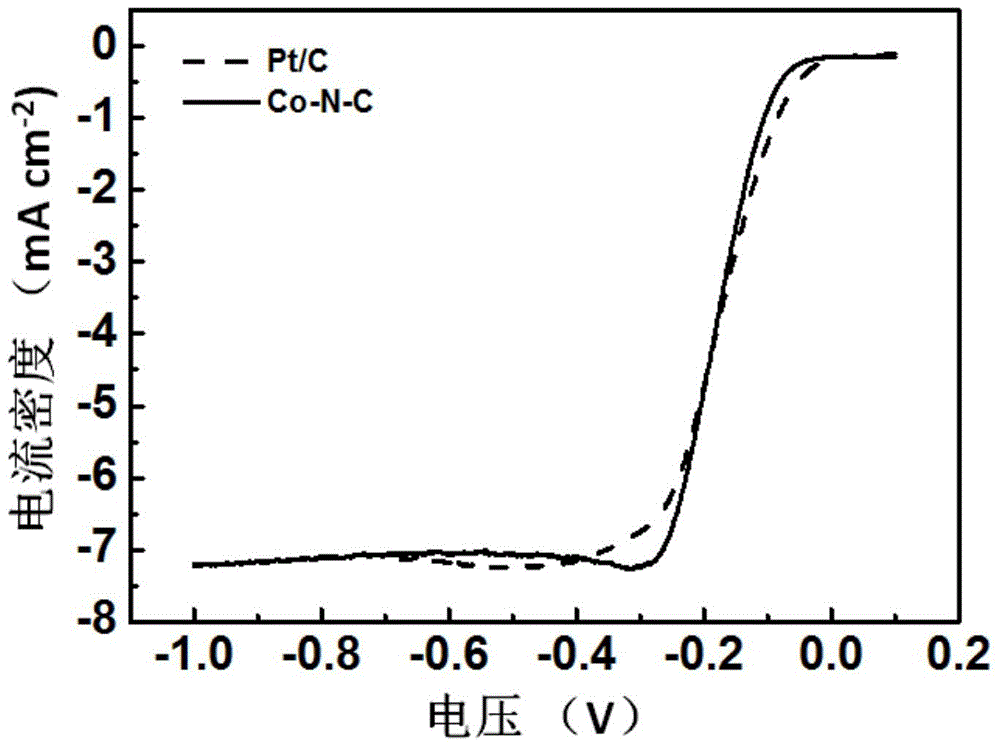

A transition metal and catalyst technology, applied in the field of cobalt-based transition metal oxygen reduction catalyst and its preparation, can solve the problems of low efficiency and low practicability of the oxygen reduction catalyst, and achieve good methanol poisoning resistance, simple preparation process and high catalytic performance. Effects of Oxygen Activity and Catalytic Stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of the cobalt-based transition metal oxygen reduction catalyst of the present invention comprises the following steps: respectively adding cobalt salt and nitrogen-containing organic ligands into ethanol to make the two fully react to form a cobalt complex solution; adding Carbon material, reflux reaction in an oil bath, so that the cobalt complex is evenly adsorbed on the surface of the carbon material; evaporate to remove ethanol, and grind the remaining material evenly to obtain a black powder; the black powder is in an inert gas environment, at 600 ~ 900 The cobalt-based transition metal oxygen reduction catalyst can be obtained by heat treatment at 0.5°C for 0.5-3 hours.

[0028] Specifically, the mass concentration of cobalt salt in ethanol is 2-4 mg / mL, the molar ratio of cobalt salt to nitrogen-containing organic ligand is 1:2, and the total mass of cobalt salt, nitrogen-containing organic ligand and carbon material is Based on 100%, the m...

Embodiment 1

[0036] 119mg of cobalt chloride hexahydrate and 198mg of phenanthroline were added to 50ml of ethanol respectively (the mass concentration of cobalt chloride hexahydrate in ethanol is 2.38mg / mL, the molar ratio of cobalt chloride hexahydrate and phenanthroline ratio of 1:2), stirred for 30 minutes to fully react the two to form a cobalt complex solution; add 438.5mg ECP600JD carbon black (based on the total mass of cobalt chloride hexahydrate, phenanthroline and carbon black) to the above solution as 100%, the mass fraction of carbon black is 58%), and then reflux reaction in an oil bath for 4 hours, so that the cobalt complex is evenly adsorbed on the surface of carbon black; use a rotary evaporator to remove ethanol, and grind the obtained sample Uniform, black powder is obtained; the black powder is transferred to a nitrogen-protected high-temperature tube furnace, and heat-treated at 700° C. for 0.5 hour, and the obtained product is a cobalt-based transition metal oxygen re...

Embodiment 2

[0046] The cobalt chloride hexahydrate and 131mg bipyridyl are joined respectively in 50ml ethanol solution (the mass concentration of cobalt chloride hexahydrate in ethanol is 2mg / mL, the mol ratio of cobalt chloride hexahydrate and bipyridine is 1: 2), stirring for 30 minutes to fully react the two to form a cobalt complex solution; add 231 mg of carbon nanotubes to the above solution (based on the total mass of cobalt chloride hexahydrate, bipyridyl and carbon nanotubes as 100%, carbon The mass fraction of the nanotubes is 50%), and then reflux reaction in an oil bath for 6 hours, so that the cobalt complex is evenly adsorbed on the surface of the carbon nanotubes; the ethanol is removed by a rotary evaporator, and the obtained sample is ground evenly to obtain a black powder; the black powder was transferred to a high-temperature tube furnace protected by argon, and heat-treated at 800° C. for 1 hour, and the obtained product was a cobalt-based transition metal oxygen reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com