Method for preparing nanometer ceramic particle doped PE diaphragm

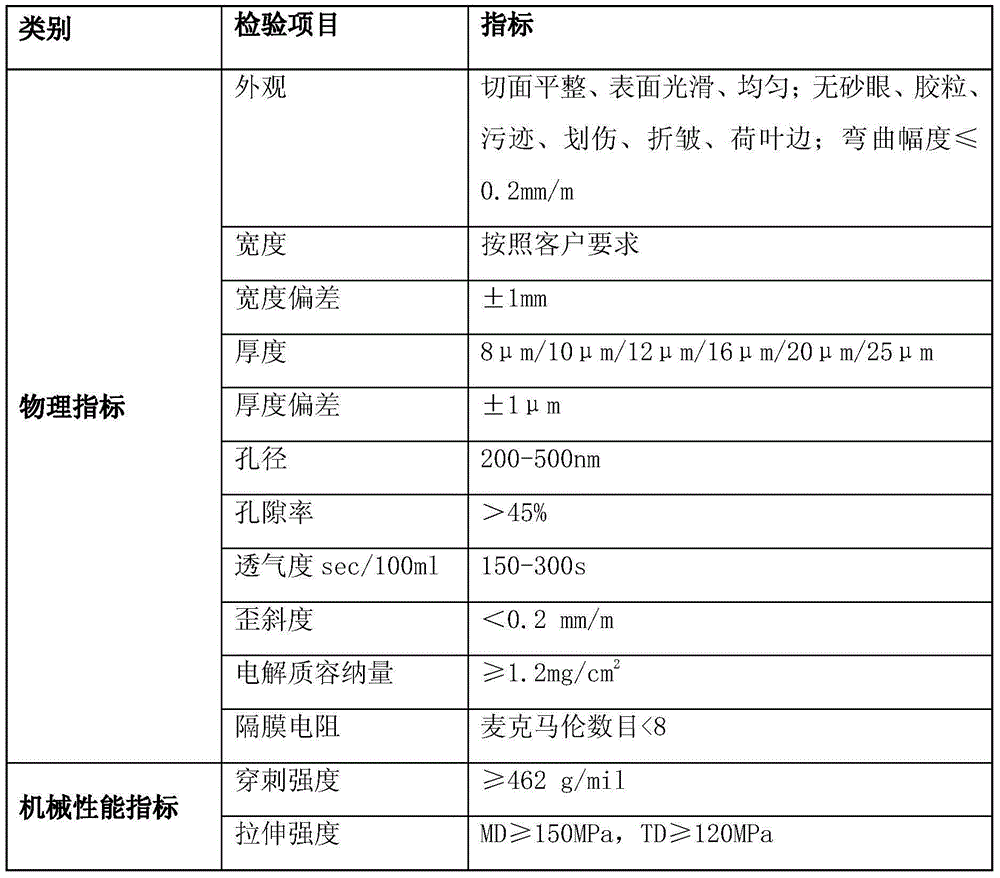

A technology of nano-ceramic particles and separators, applied in electrical components, circuits, battery pack parts, etc., can solve the problem of weak adhesion between inorganic nano-ceramic particles and substrates, incomplete electrospinning technology theory, coating thickness and porosity. The problem of uneven rate control can be improved to improve the charge-discharge cycle performance, increase the high-rate charge-discharge performance, and achieve good consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The present invention, a kind of preparation method of nano-ceramic particle doped PE diaphragm, comprises the following steps:

[0029] Step 1: Ingredients, first prepare the mixture A, according to the weight ratio of polyethylene, white oil and aluminum oxide is 12:85:3, weigh each component, first add the white oil into the reaction kettle for heating and stirring , add polyethylene and aluminum oxide in turn, stir well to make it evenly mixed, and obtain mixture A;

[0030] Step 2: extruding and casting, the mixture A in the above step 1 undergoes solid-liquid phase or liquid-liquid phase separation after cooling down, and extrudes through a twin-screw extruder to obtain extruded cast flakes;

[0031] Step 3: Two-way synchronous stretching, the above-mentioned extruded cast sheet enters a bidirectional synchronous stretching machine to obtain a film with uniform thickness; the bidirectional synchronous stretching machine is selected, and the obtained separator has ...

Embodiment 2

[0040] Step 1: Ingredients, first prepare the mixture A, according to the weight ratio of polyethylene, white oil and silicon dioxide is 12:85:3, weigh each component, first add the white oil into the reaction kettle for heating and stirring, Add polyethylene and aluminum oxide in turn, stir well to make it evenly mixed, and then get mixture A;

[0041] Step 2: extruding and casting, the mixture A in the above step 1 undergoes solid-liquid phase or liquid-liquid phase separation after cooling down, and extrudes through a twin-screw extruder to obtain extruded cast flakes;

[0042] Step 3: Two-way synchronous stretching, the above-mentioned extruded cast sheet enters a bidirectional synchronous stretching machine to obtain a film with uniform thickness; if a bidirectional synchronous stretching machine is selected, the strength of the obtained diaphragm in the horizontal and vertical directions is uniform, and the heat shrinkage rate is low and the difference is small;

[0043]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com