Preparation method of positive active material hollow spherical lithium manganate of lithium ion battery

A positive electrode active material, spherical lithium manganese oxide technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as difficulty in ensuring uniform mixing of reaction raw materials, uneven size and structure of products, and damage to the structure of reaction raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

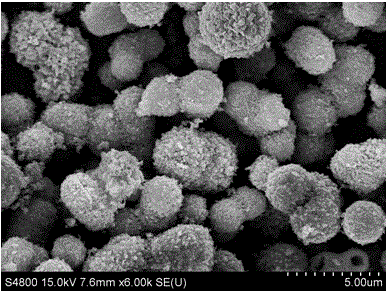

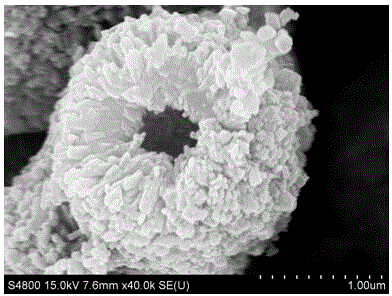

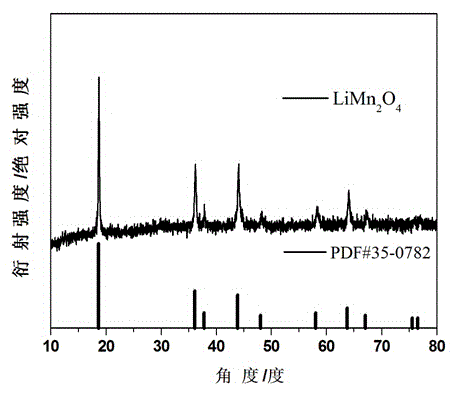

[0025] 1. Preparation of hollow manganese dioxide spheres: 3.0g of MnSO 4 ·H 2 O was added to 30ml deionized water, and 4g of K 2 S 2 o 8 Dissolve in 35ml of deionized water, then mix the two solutions, stir evenly with a mechanical stirrer, add 3ml of concentrated sulfuric acid dropwise, transfer to a stainless steel reaction kettle lined with polytetrafluoroethylene, react at a temperature of 110°C for 8 hours, and then Centrifuge to obtain a solid phase, wash and dry the solid phase to obtain hollow manganese dioxide spheres.

[0026] 2. Preparation of hollow spherical lithium manganate: take Li with a concentration of 0.1 mol / L 2 CO 3 40ml of aqueous solution, then add 0.2g of manganese dioxide spheres, continue ultrasonic treatment for 30 minutes, the conditions of ultrasonic treatment are: 50KHz, then dry ethanol, and then calcined at 700°C for 6h, the final product is hollow spherical lithium manganate.

Embodiment 2

[0028] 1. Preparation of hollow manganese dioxide spheres: 1.5g of MnSO 4 ·H 2 O was added to 25ml deionized water, and 3g of K 2 S 2 o 8 Dissolve in 30ml of deionized water, then mix the two solutions, stir evenly with a mechanical stirrer, add 2ml of concentrated sulfuric acid dropwise, transfer to a stainless steel reaction kettle lined with polytetrafluoroethylene, react at 110°C for 8 hours, and then Centrifuge to obtain a solid phase, wash and dry the solid phase to obtain hollow manganese dioxide spheres.

[0029] 2. Preparation of hollow spherical lithium manganese oxide: Take 40ml of LiCl aqueous solution with a concentration of 0.1 mol / L, then add 0.2g of manganese dioxide balls, and continue ultrasonication for 25 minutes. The conditions of ultrasonic treatment are: 50KHz, then dry ethanol, and then 750 Calcined at ℃ for 6h, the final product is hollow spherical lithium manganate.

Embodiment 3

[0031] 1. Preparation of hollow manganese dioxide spheres: mix 1.0g of MnSO 4 ·H 2 O was added to 15ml of deionized water, and 2g of K 2 S 2 o 8 Dissolve in 15ml of deionized water, then mix the two solutions, stir evenly with a mechanical stirrer, add 2ml of concentrated sulfuric acid dropwise, transfer to a stainless steel reaction kettle lined with polytetrafluoroethylene, react at 110°C for 6 hours, The solid phase is obtained by centrifugation, and the solid phase is washed and dried to obtain hollow manganese dioxide spheres.

[0032] 2. Preparation of hollow spherical lithium manganate: take LiOH·H with a concentration of 0.2 mol / L 2 O aqueous solution 20ml, then add manganese dioxide spheres 0.1g, continue ultrasonication for 25 minutes, the conditions of ultrasonic treatment are: 50KHz, then dry ethanol, and then calcined at 500°C for 5h, the final product is hollow spherical lithium manganate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com