Method for removing ammonia nitrogen in electroplating wastewater

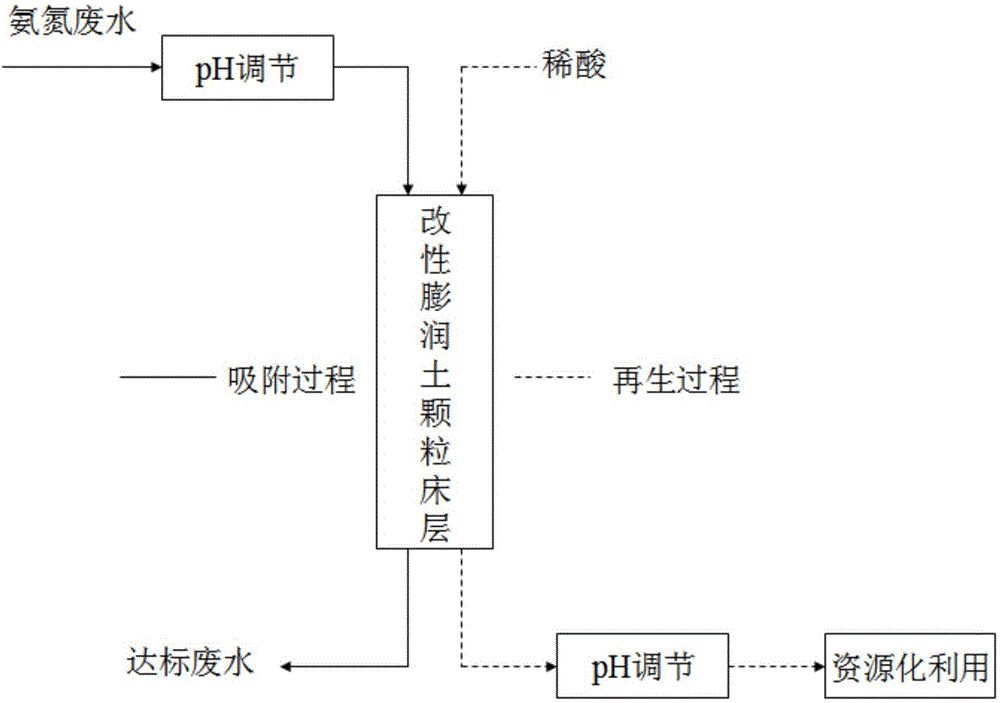

A technology for electroplating wastewater and ammonia nitrogen, which is applied in separation methods, metallurgical wastewater treatment, chemical instruments and methods, etc., can solve problems such as secondary pollution, and achieve the effect of promoting the adsorption process, simplifying the process, and restoring the adsorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

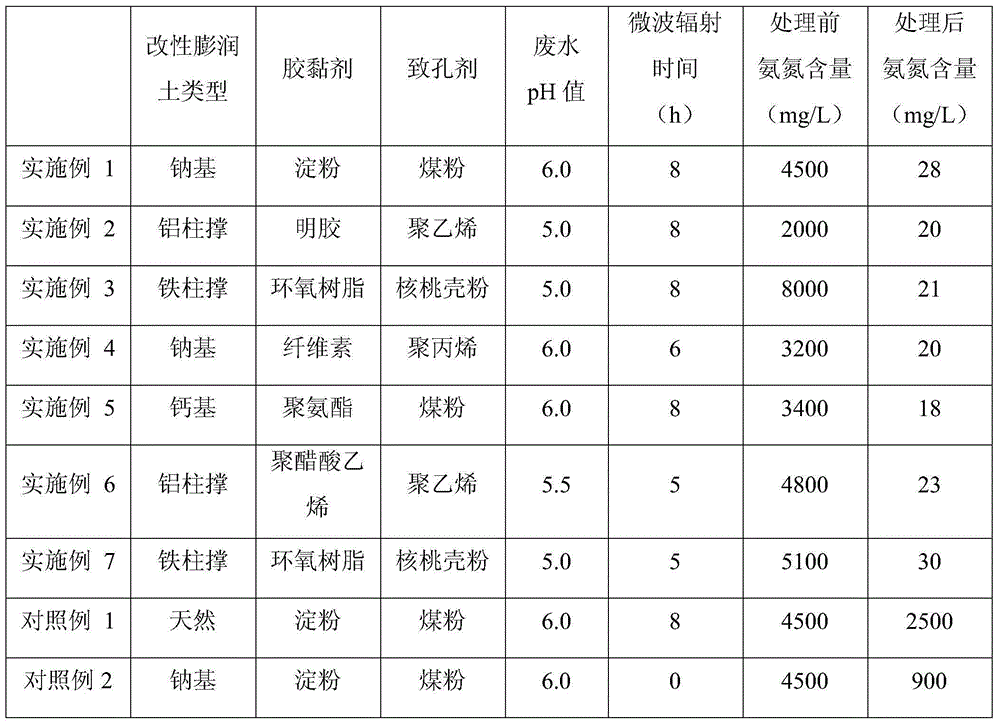

Embodiment 1

[0038] A, preparation of sodium bentonite particles

[0039] Take 100g of natural bentonite, slowly add 500mL of 4% sodium nitrate solution under rapid stirring, raise the temperature to 50°C and stir for 12 hours. Then add 30 g of coal powder and 5 g of starch, and stir for 12 hours; filter the suspension to obtain a filter cake, and wash the filter cake with 100 mL of deionized water to remove nitrate ions. Place the filter cake in a constant temperature drying oven at 90°C to dry to constant weight, then transfer to a muffle furnace for calcination at 900°C for 3 hours; after calcination, the solid particles are cooled and sieved through a sieve, and 8-15 mesh particles are selected for use .

[0040] B. Treatment of ammonia nitrogen wastewater

[0041] The above-mentioned 50g sodium-based bentonite particles are packed into a 5cm diameter, and the obtained bed height is 20cm. Place the bed section in a microwave oven, and control the temperature to 80°C by adjusting the...

Embodiment 2

[0045] A. Preparation of aluminum pillared bentonite particles

[0046] Slowly add 100mL of NaOH aqueous solution with a mass concentration of 1mol / L dropwise into 100mL of an aluminum nitrate solution with a mass concentration of 0.5mol / L, and the obtained aluminum hydroxide columnizer is aged for 3 days, and then slowly added 100g of sodium bentonite prepared according to Example 1 was put into the above-mentioned aluminum hydroxide columning agent, and allowed to stand for 12 hours. Continue to add 20g polyethylene and 3g gelatin, and stir for 12 hours; filter the suspension to obtain a filter cake, wash the filter cake with 100mL deionized water, and wash away the nitrate ions; place the filter cake in a constant temperature drying oven at 100°C to dry to constant weight , transferred to a muffle furnace for calcination at 800°C for 4 hours; after calcination, the solid particles were cooled, passed through a sieve for sieving, and 8-15 mesh particles were selected for use...

Embodiment 3

[0052] A. Preparation of iron pillared bentonite particles

[0053] 50 mL of NaOH aqueous solution with a mass concentration of 1 mol / L was slowly added dropwise into 50 mL of a ferric nitrate solution with a mass concentration of 0.5 mol / L, and the obtained ferric hydroxide columnar agent was left to age for 2 days. Then slowly add 100 g of the sodium bentonite prepared according to Example 1 to the ferric hydroxide columning agent while stirring, and let it stand for 12 hours. Continue to add 20g of walnut shell powder and 3g of epoxy resin adhesive, and stir for 12 hours. Filter the suspension to obtain a filter cake, wash the filter cake with 100mL deionized water to remove nitrate ions; place the filter cake in a constant temperature drying oven at 100°C to a constant weight, transfer to a muffle furnace and calcinate at 850°C for 4 hours . After calcination, the solid particles are cooled, sieved through a sieve, and 8-15 mesh particles are selected for use.

[0054] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com