Composite material containing fluorine-containing titanium phosphate compound as well as preparation method and application of composite material

A composite material and compound technology, which is applied to the composite material containing fluorine-containing titanium phosphate compound and the fields of its preparation and use, can solve the problems of slow sodium ion migration kinetics and the like, and achieve the effect of improving the charging and discharging performance of high current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

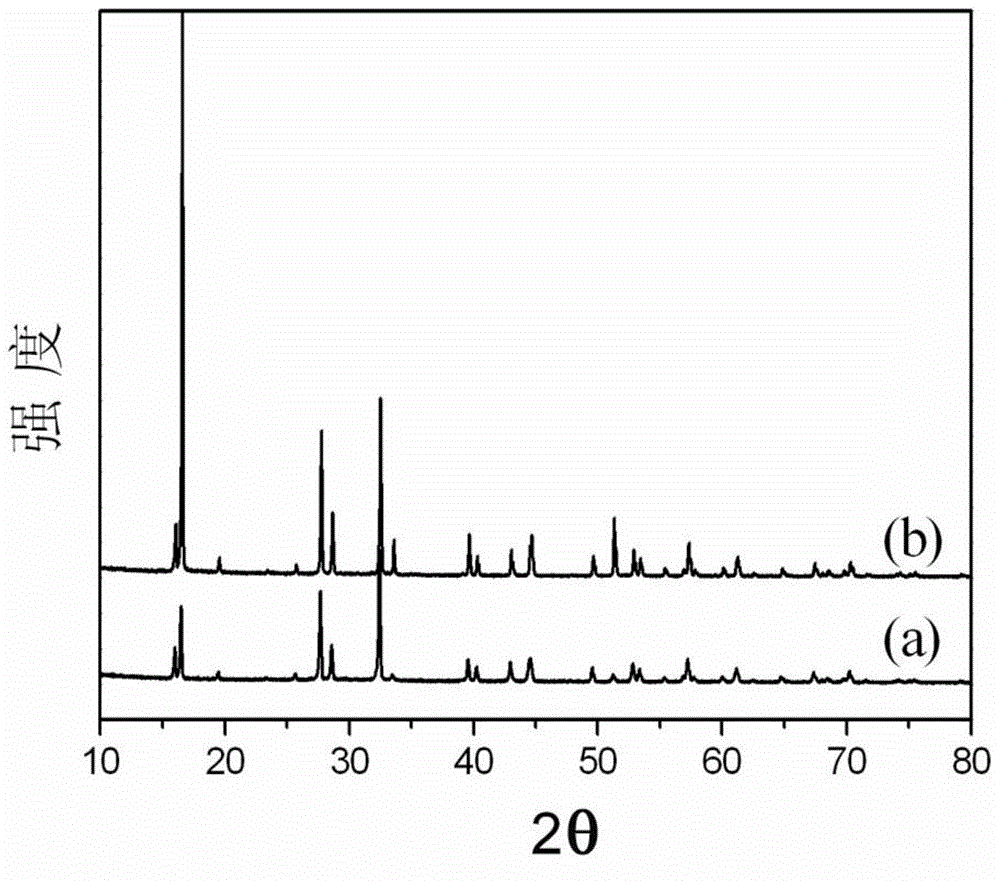

[0083] This example is used to illustrate the fluorine-containing titanium phosphate compound (Na 3 [Ti 2 P 2 o 10 F]) and methods for their preparation.

[0084] Specifically, a hydrothermal method was used to prepare Na 3 [Ti 2 P 2 o 10 F]·xH 2 O, the specific steps include:

[0085] (1) 6g of analytically pure titanium sulfate (Ti(SO 4 ) 2 ), 36g sodium borate (NaBO 3 4H 2 O), 19g ammonium dihydrogen phosphate and 3g sodium fluoroborate (NaBF 4 ) was mixed with 20mL of deionized water and stirred evenly to prepare a mixture solution;

[0086] (2) Put the mixture solution prepared in step (1) into a 50mL stainless steel autoclave lined with polytetrafluoroethylene, seal it, heat it at 200°C for 2 days, and then cool it to room temperature to obtain a white product;

[0087] (3) Wash the white product obtained in step (2) with water and ethanol, and dry it at room temperature to obtain Na 3 [Ti 2 P 2 o 10 F]·xH 2 O sample;

[0088] (4) Na obtained in step ...

Embodiment 2

[0092] This example is used to illustrate the fluorine-containing titanium phosphate compound (Na 3 [Ti 2 P 2 o 10 F]) and methods for their preparation.

[0093] Specifically, a hydrothermal method was used to prepare Na3 [Ti 2 P 2 o 10 F]·xH 2 O, the specific steps include:

[0094] (1) Add 6g of titanium sulfate (Ti(SO 4 ) 2 ), 36g sodium borate (NaBO 3 4H 2 O), 12 mL of 85% H 3 PO 4 and 3 g sodium fluoroborate (NaBF 4 ) mixed with 10mL of ammonia water with a concentration of 25-28%, and stirred evenly to prepare a mixture solution;

[0095] (2) Put the mixture solution prepared in step (1) into a 50mL stainless steel autoclave lined with polytetrafluoroethylene, seal it, heat it at 200°C for 7 days, and then cool it to room temperature to obtain a white product;

[0096] (3) Wash the white product obtained in step (2) with water and ethanol, and dry it at room temperature to obtain Na 3 [Ti 2 P 2 o 10 F]·xH 2 O sample;

[0097] (4) Na obtained in step...

Embodiment 3

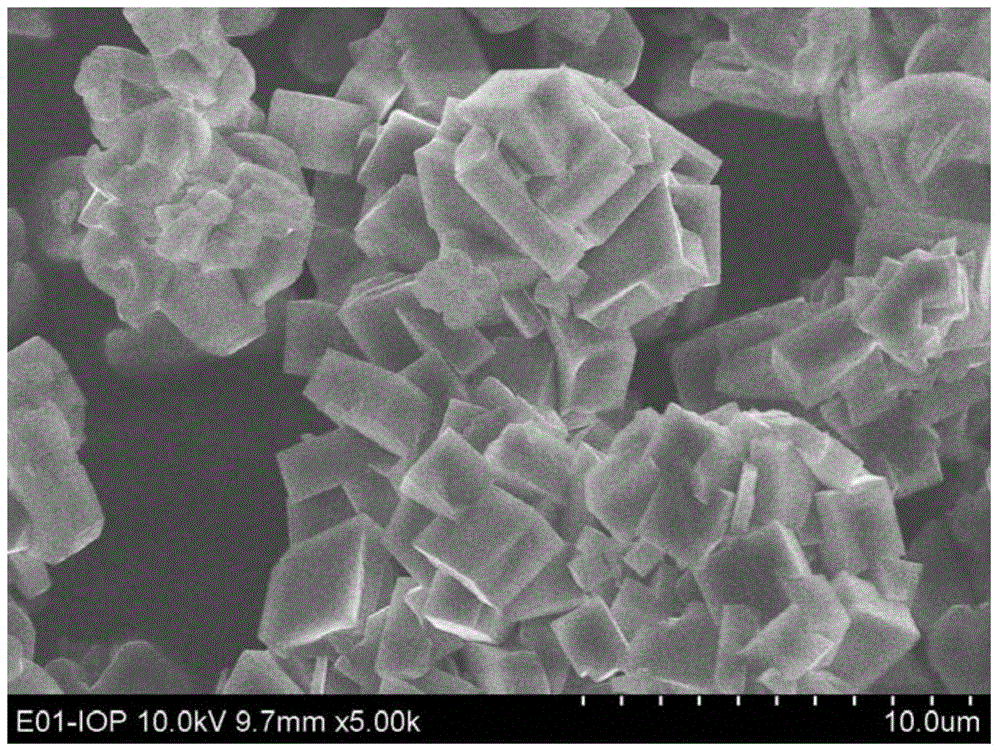

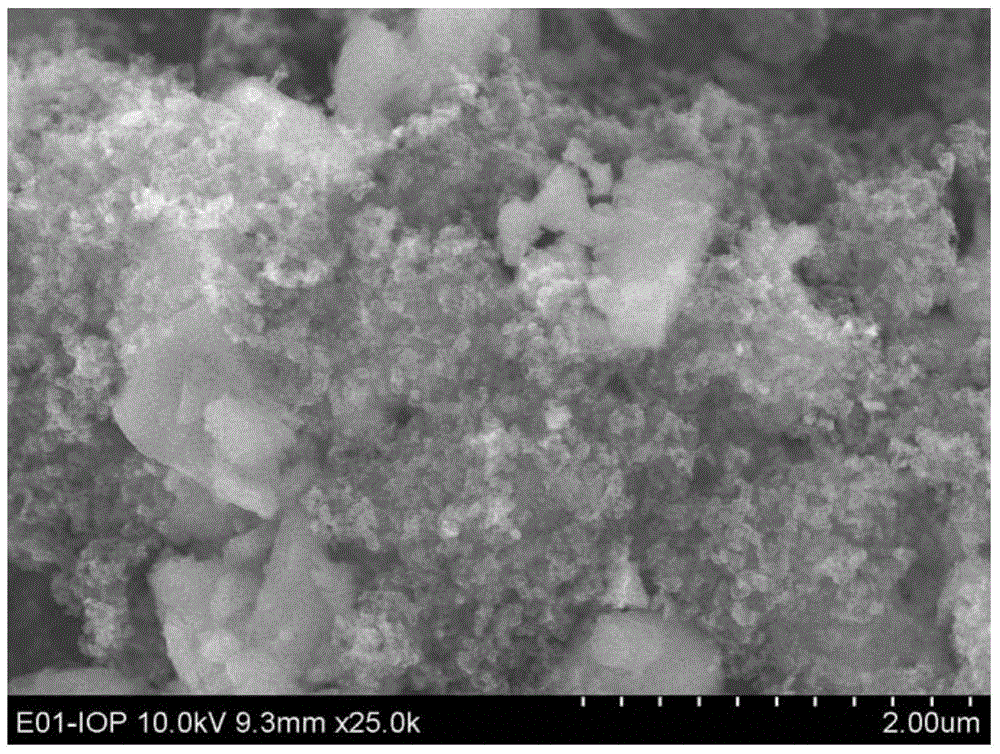

[0100] This example is used to illustrate the fluorine-containing titanium phosphate compound (Na 3 [Ti 2 P 2 o 10 F]) and carbon black composite Na 3 [Ti 2 P 2 o 10 F]-30wt% carbon black and its preparation method.

[0101] The fluorine-containing titanium phosphate compound (Na 3 [Ti 2 P 2 o 10 F]) powder and 30 parts by weight of commercial carbon black (model KS-6, particle size 200nm ~ 50μm, purchased from Dongguan New Energy Technology Co., Ltd.) were mixed, put into a ball mill jar, and absolute ethanol was added as a ball mill medium. Mixed by ball milling for 10 hours and then dried at room temperature to obtain the composite Na 3 [Ti 2 P 2 o 10 F]-30wt% carbon black, the number is No.1.

[0102] Adopt scanning electron microscope to observe the composite material Na that embodiment 3 makes 3 [Ti 2 P 2 o 10 F]-30wt% carbon black size and morphology, the results are as image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com