Preparation method and application of compounded carrier supported olefin polymerization catalyst

A compound carrier and olefin polymerization technology, which is applied in the field of supported olefin polymerization catalysts, can solve the problems of poor polymer morphology, low catalytic activity, and easy breakage, and achieve adjustable and controllable viscosity-average molecular weight of ultra-high molecular weight polyethylene. , high bulk density and moderate molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

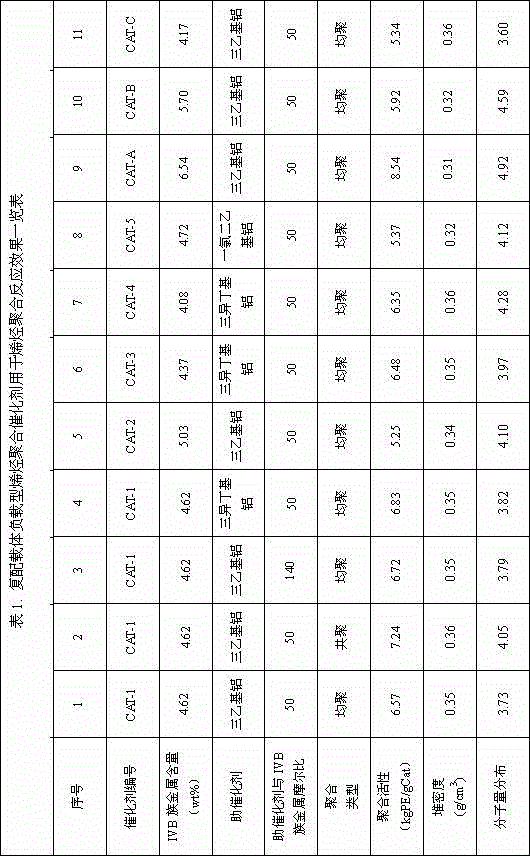

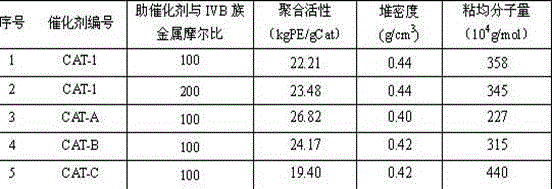

Examples

preparation example Construction

[0015] The invention relates to a preparation method of a composite carrier-supported olefin polymerization catalyst, comprising the following steps: dissolving a magnesium compound in a solvent in the presence of alcohol to obtain a magnesium compound solution, adding a porous carrier and mixing the magnesium compound solution, Obtain a mixed slurry, and then add a precipitant or dry the mixed slurry to obtain a composite carrier, and pass the composite carrier through a silicon-containing compound such as a siloxane compound, a halosiloxane compound or a silicon halide and a compound selected from IVB The chemical treatment agents of group metal halides are sequentially treated to obtain a compound carrier-supported olefin polymerization catalyst.

[0016] According to the present invention, examples of the magnesium compound include magnesium halide, alkoxymagnesium halide, alkoxymagnesium and alkylmagnesium halide.

[0017] Specifically, the magnesium halide is selected fr...

Embodiment 1

[0095] Anhydrous magnesium chloride is used as the magnesium compound, tetrahydrofuran is used as the solvent, ethanol is used as the alcohol, and silica gel is used as the porous carrier. First, the silica gel is thermally activated by continuously roasting the silica gel at 600° C. for 4 hours under a nitrogen atmosphere. The silicon-containing compound adopts tetraethoxy silicon, and the IVB group chemical treatment agent adopts titanium tetrachloride.

[0096] Weigh 5 grams of magnesium compound, add it to the solvent, then add alcohol, completely dissolve at room temperature to obtain a magnesium compound solution, then add a porous carrier, stir for 2 hours to obtain a mixed slurry, then evenly heat to 80 ° C, and directly vacuum dry , to obtain the composite carrier. Add the composite carrier to the hexane solvent, add the silicon-containing compound dropwise within 5 minutes at room temperature, and after 15 minutes of reaction, add the IVB group chemical treatment agent...

Embodiment 2

[0101] Basically the same as Example 1, but with the following changes:

[0102] The magnesium compound was changed to isobutoxymagnesium chloride, the alcohol was changed to n-butanol, the solvent was changed to toluene, the porous carrier was changed to titanium dioxide, and thermal activation was achieved by continuous calcination at 400°C for 4 hours under a nitrogen atmosphere. The silicon-containing compound was changed to tetraisobutoxy silicon, and the chemical treatment agent was changed to zirconium tetrachloride (ZrCl 4 ).

[0103] The mixed slurry was changed to adding a precipitating agent hexane to make it completely precipitated, filtered and washed three times with a precipitating agent, and then vacuum-dried at 60°C.

[0104] The ratio is as follows: the mass ratio of magnesium compound to porous carrier is 1:1; the molar ratio of magnesium to alcohol is 1:1; the ratio to solvent is 1mol:250ml; the molar ratio to chemical treatment agent is 1 : 0.30; the mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com