A Fusible Elastomer Modified Asphalt Waterproof Membrane

A kind of asphalt waterproof membrane and body modification technology, which is applied in the direction of asphalt layered products, layered products, synthetic resin layered products, etc., and can solve the problems of improvement and promotion of modified asphalt construction performance, consumption of fossil fuels, waste of resources, etc. problems, to save energy consumption, improve construction speed, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

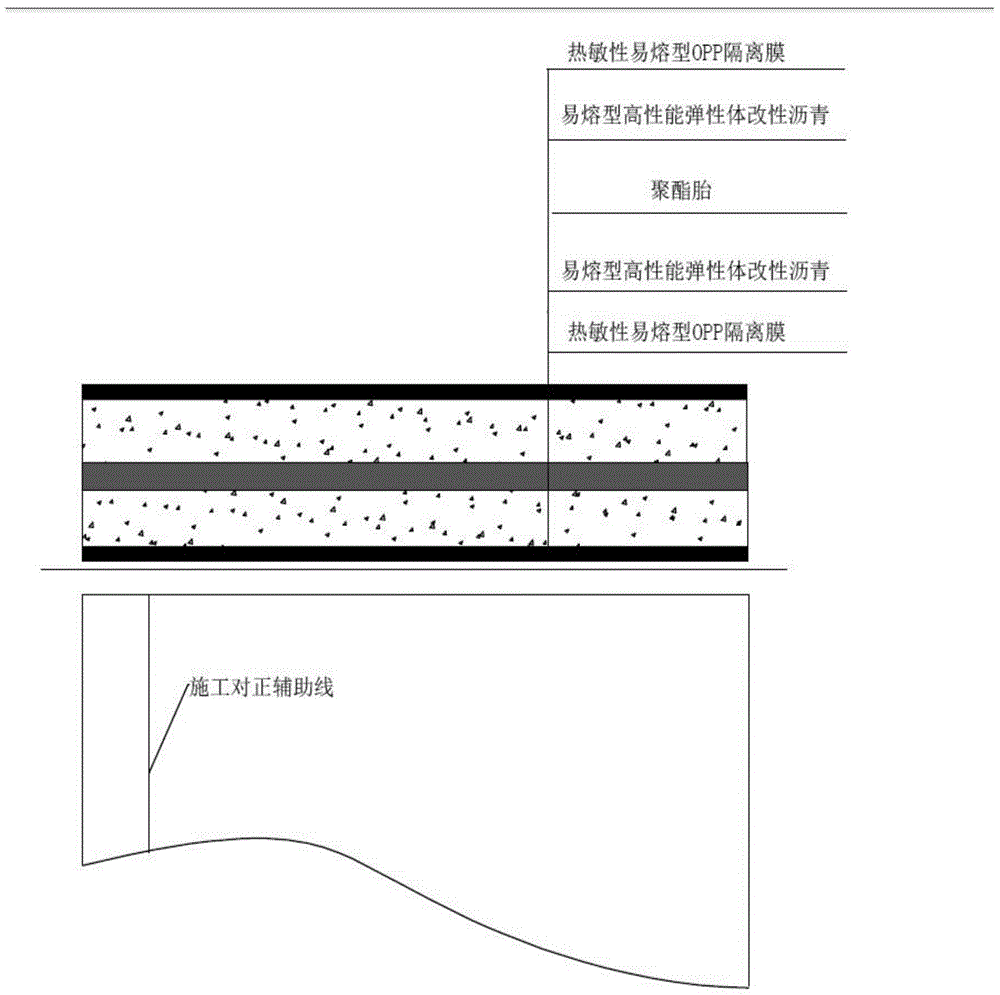

[0039] Polyester tire specification selection weight is 250g / m 2 , with a thickness of 1.6mm; the upper and lower surface thicknesses of the fusible elastomer modified asphalt are 1.0mm and 1.1mm respectively;

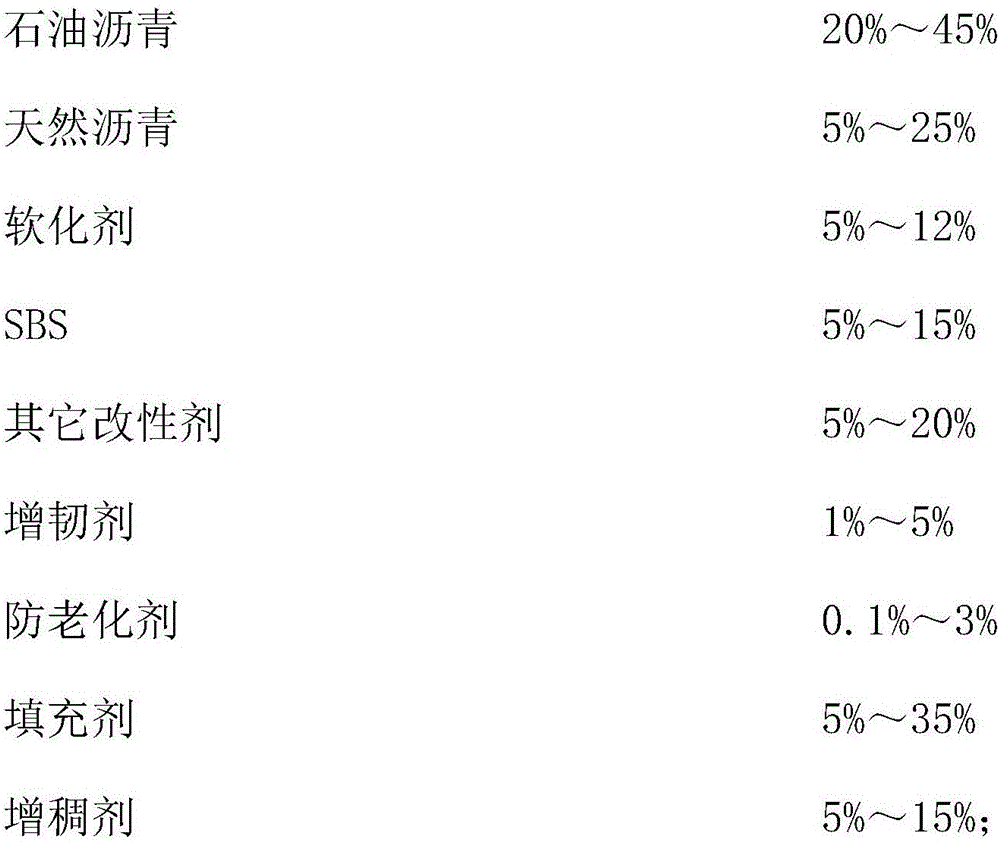

[0040] 1. The rubber composition of fusible elastomer modified asphalt is as follows:

[0041]

[0042]

[0043] Preparation method of fusible elastomer modified asphalt:

[0044] (1) 35% petroleum asphalt and 14% natural lake asphalt are heated to 150°C;

[0045] (2) Add 5% naphthenic oil, 8% SBS4402, 5% styrene-butadiene rubber and 2% acrylate rubber in sequence, stir evenly, and heat up to 185°C. Develop at this temperature for 40 minutes, then turn on the colloid mill to accelerate the swelling process and make the modifier more complete.

[0046] (3) Stop the colloid mill after two hours, add 25.8% heavy calcium carbonate and 5% attapulgite, and continue to develop at a temperature of 185° C. for 70 minutes.

[0047](4) Finally, add 0.2% light stabilizer...

Embodiment 2

[0061] Polyester tire specification selection weight is 200g / m 2 , with a thickness of 1.2mm; the upper and lower surface thicknesses of the fusible elastomer modified asphalt are 1.0mm and 1.2mm respectively, and the heat-sensitive fusible OPP isolation film layers on the upper and lower surfaces are both 0.01mm.

[0062] 1. The rubber composition of fusible elastomer modified asphalt is as follows:

[0063]

[0064]

[0065] Preparation method of fusible elastomer modified asphalt:

[0066] (1) 42% petroleum asphalt and 15% natural lake asphalt are heated to 160°C;

[0067] (2) Add 8% minus first-line engine oil, 12% SBS4402, 5% butadiene rubber and 2% acrylic ester rubber in turn, stir evenly, and heat up to 190°C. Develop at this temperature for 30 minutes, then turn on the colloid mill to accelerate the swelling process and make the modifier more complete.

[0068] (3) Stop the colloid mill after two hours, add 10.5% heavy calcium carbonate and 5% attapulgite, an...

Embodiment 3

[0083] Polyester tire specification selection weight is 220g / m 2 , the thickness is 1.35mm; the thickness of the mineral granular material layer is 0.7mm, the thickness of the upper and lower surfaces of the high heat-resistant elastomer modified asphalt is 1.1mm and 1.3mm respectively, and the thickness of the heat-sensitive and fusible OPP isolation film layer on the upper and lower surfaces is 0.01mm.

[0084] 1. The rubber composition of fusible elastomer modified asphalt is as follows:

[0085]

[0086]

[0087] Preparation method of fusible elastomer modified asphalt:

[0088] (1) 40% petroleum asphalt and 11% natural lake asphalt are heated to 160°C;

[0089] (2) Add 5% naphthenic oil, 12% SBS4402, 5% ethylene-propylene rubber and 2% acrylic rubber in sequence, stir evenly, and heat up to 180°C. Develop at this temperature for 45 minutes, then turn on the colloid mill to accelerate the swelling process and make the modifier more complete.

[0090] (3) Stop the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com