A kind of preparation method of additive for cereal beverage

A cereal beverage and additive technology, applied in the field of food additives, can solve the problems of sedimentation and stratification, poor homogeneity, etc., and achieve the effect of improving dispersion and stability and preventing stratification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

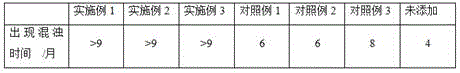

Examples

Embodiment 1

[0021] Step 1: Take 60Kg of thinned brokey pineapple, peel and remove the core, grind the thinned brokey pineapple meat into a puree to obtain a puree; add 200kg of water to the puree, and add acetic acid to adjust the pH To 4, stand still for 10 hours, take the supernatant, then add 100Kg of 95vol.% ethanol in the supernatant, after stirring evenly, leave standstill for 12 hours, to obtain the ethanol solution of shrunken brokey pineapple; Heating and concentrating until the concentrated solution is a thick paste with a relative density of 1.40 at 50°C to obtain a thin brokey pineapple concentrated solution;

[0022] Step 2: Freeze-dry the thinned brokey pineapple concentrate, the freeze-drying process parameters are temperature -60°C, vacuum 10Pa; sampling every 2 hours until the mass of the freeze-dried material within every 2 hours The loss is not more than 0.1%, and the freeze-dried powder is obtained;

[0023] Step 3: Steam 20-30 kg of sea cucumbers, take them out, cut ...

Embodiment 2

[0026] Step 1: Take 90Kg of thinned brokey pineapple, peel and remove the core, and grind the thinned brokey pineapple meat into a puree to obtain a puree; add 400kg of water to the puree, and add acetic acid to adjust the pH To 5, stand still for 15 hours, get the supernatant, then add 120Kg of 95vol.% ethanol in the supernatant, after stirring evenly, leave standstill for 15 hours, to obtain the ethanol solution of shrunken brokey pineapple; Heating and concentrating until the concentrated solution is a thick paste with a relative density of 1.50 at 50° C. to obtain a thin brokey pineapple concentrated solution;

[0027] Step 2: Freeze-dry the thinned brokey pineapple concentrate, the freeze-drying process parameters are temperature -40°C, vacuum 30Pa; sampling every 2 hours until the mass loss of the freeze-dried material within every 2 hours Not more than 0.1%, to obtain freeze-dried powder;

[0028] Step 3: steam 30 kg of sea cucumber, take it out, cut it into small piec...

Embodiment 3

[0031] Step 1: Take 70Kg of thinned brokey pineapple, peel and remove the core, and grind the thinned brokey pineapple meat into a puree to obtain a puree; add 300kg of water to the puree, and add acetic acid to adjust the pH To 4, stand still for 12 hours, get the supernatant, then add 110Kg of 95vol.% ethanol in the supernatant, after stirring evenly, leave standstill for 13 hours, to obtain the ethanol solution of shrunken brokey pineapple; Heating and concentrating until the concentrated solution is a thick paste with a relative density of 1.44 at 50°C to obtain a thin brokey pineapple concentrated solution;

[0032] Step 2: Freeze-dry the thinned brokey pineapple concentrate, the freeze-drying process parameters are temperature -50°C, vacuum degree 20Pa; sampling every 2 hours until the mass loss of the freeze-dried material within every 2 hours Not more than 0.1%, to obtain freeze-dried powder;

[0033] Step 3: steam 25 kg of sea cucumber, take it out, cut it into small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com