Nitrogen-enriched active biomass coke and preparation method thereof

A technology of activated coke and biomass, applied in separation methods, biofuels, chemical instruments and methods, etc., can solve the problems of poor safety, low adsorption efficiency, low selective adsorption value, multi-energy, etc. Achieve the effect of resource utilization and improvement of physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below can be combined with each other as long as they do not constitute a conflict with each other.

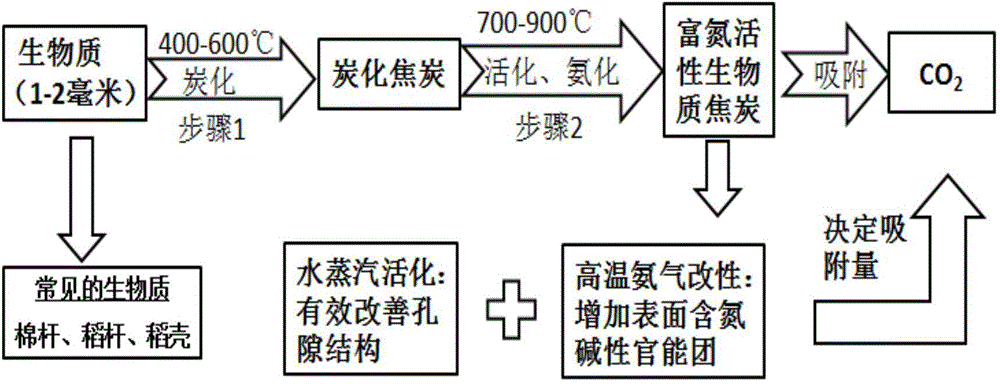

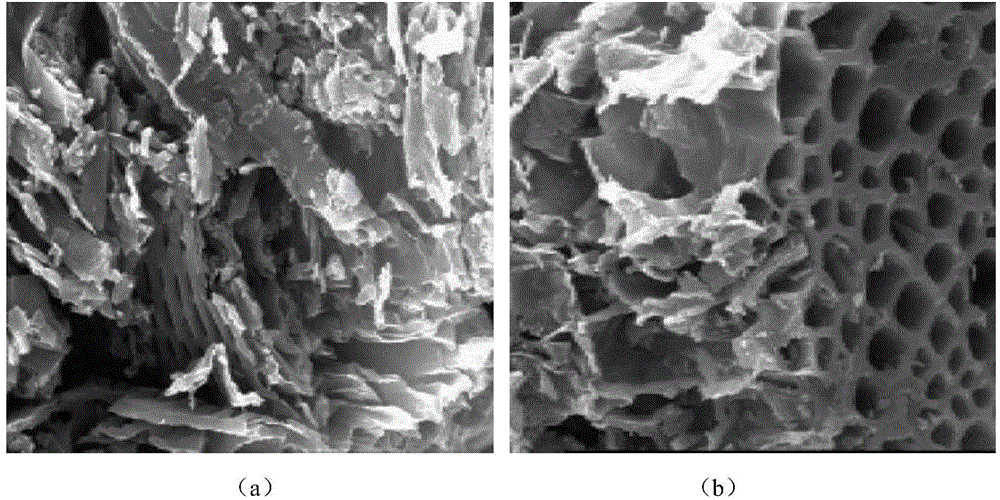

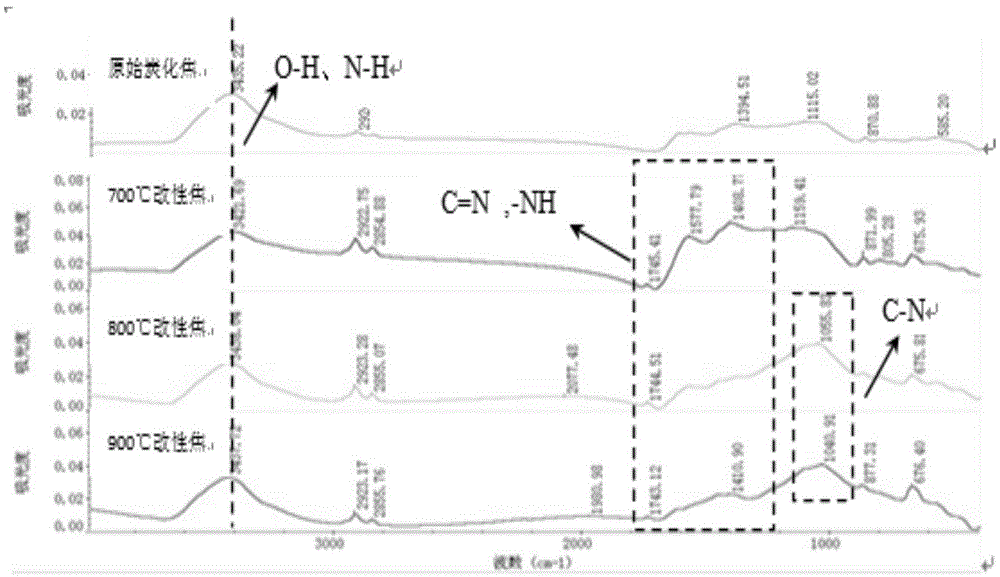

[0032] According to the first embodiment of the present invention, the method for preparing nitrogen-enriched active biomass coke constructed according to the embodiment of the present invention, its specific steps are as follows:

[0033] In this example, the biomass used is cotton stalks. The original cotton stalk biomass, in which the elemental analysis is based on the air-dry basis, shows t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com