High-efficiency street lamp flip-chip cob light source and its production process

A high-efficiency, flip-chip technology, applied in circuits, electrical components, semiconductor devices, etc., can solve problems such as inconsistent thermal expansion coefficients of chips, silver glue and brackets, light sources that cannot withstand long-term high-current stable work, and low luminous efficiency of light sources. Achieve good thermoelectric separation effect, solve the problem of heat dissipation, and have good anti-vibration stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

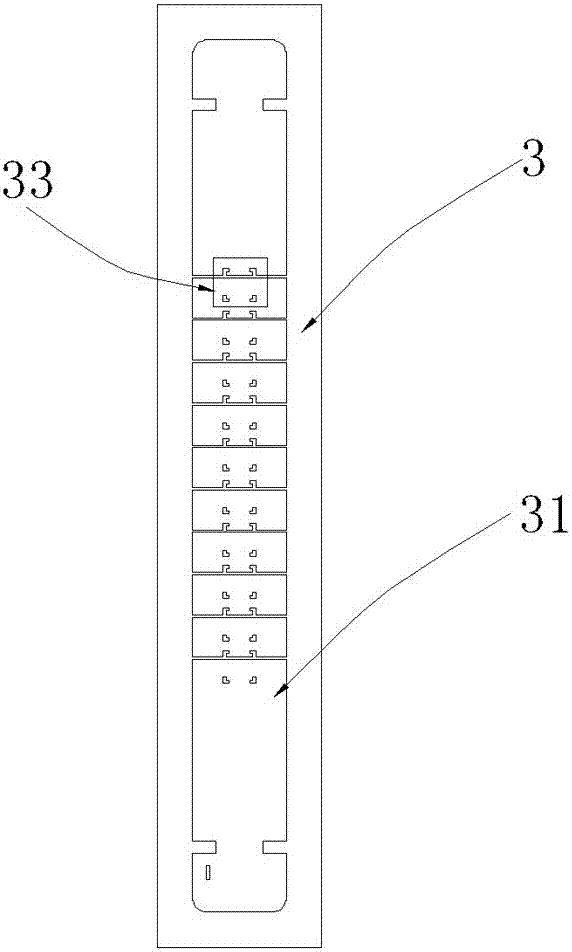

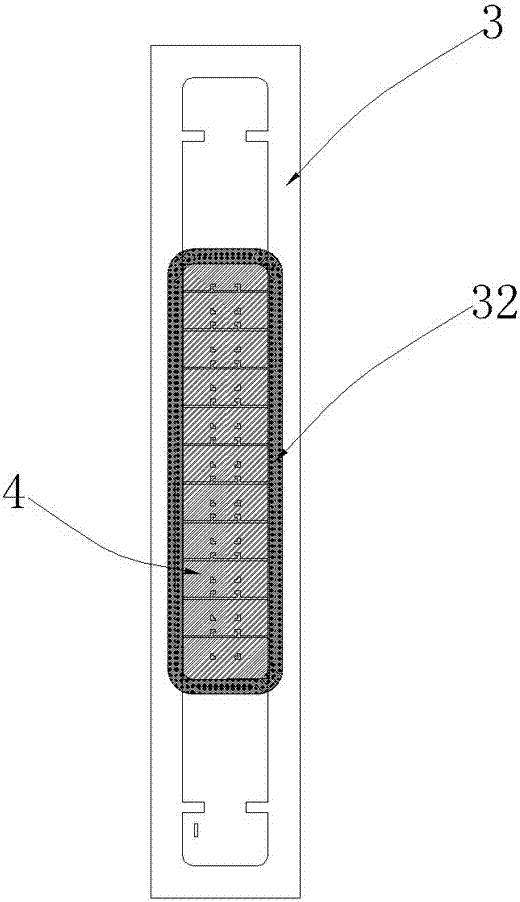

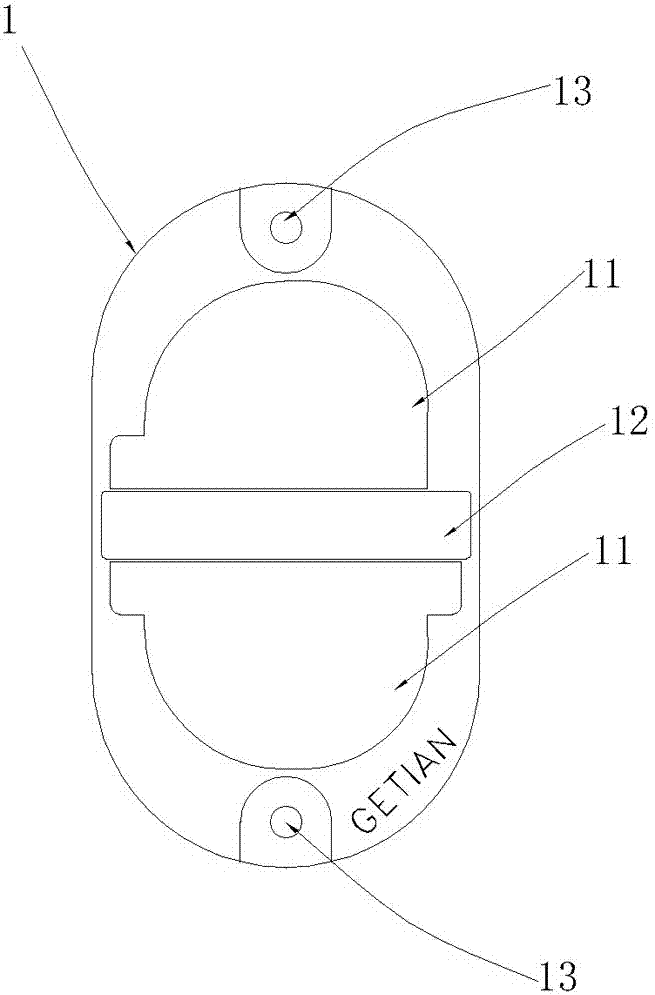

[0065] see Figure 1-8 , The high-efficiency street lamp flip-chip COB light source provided by the present invention includes a copper heat dissipation substrate 1 made of red copper material, a lens 2 made of high borosilicate glass material, an alumina ceramic bracket 3 and a flip chip 4;

[0066] Alumina ceramic supports 3 are plated with silver to form a silver layer on the surface, and the alumina ceramic supports 3 are provided with a crystal-fixing area 31, and the flip chip 4 passes through the eutectic furnace under the protection of nitrogen atmosphere. Flip-chip onto the crystal-bonding area 31 of the alumina ceramic support 3; and the surface of the flip-chip 4 is evenly coated with phosphor glue;

[0067] Two copper foil circuit areas 11 are distributed on one side of the red copper heat dissipation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com