High temperature resistant inorganic catalytic coating and porous honeycomb metal combustion plate coated with the coating

A technology of honeycomb metal and catalytic coating, which is applied in the field of porous honeycomb metal combustion plates, can solve the problems of accelerated carrier pulverization, lack of catalytic combustion effect, thinning, etc., and achieves excellent resistance to sudden cooling and heat, good Catalytic combustion performance, the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

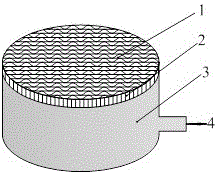

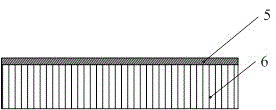

[0022] figure 1 It is an infrared combustion plate coated with a high-performance catalytic combustion catalyst, packaged and fixed in the combustion chamber shell of the burner; the gas raw material passing through the metal honeycomb combustion fire hole 1 control valve and the combustion air passing through the metal honeycomb combustion plate 2 control valve, According to the set amount, it enters the gas mixing chamber 3 for uniform mixing; the mixed gas is input into the combustion chamber of the metal carrier channel 6 infrared combustion unit through the pipeline and then evenly distributed, and the gas forms a uniform gas between the fire holes of the infrared combustion plate. Then the gas and air inlet 4 are ignited to start combustion. Under the action of the high-performance combustion-supporting catalyst, the gas burns violently and fully, and a large amount of heat energy is directly transferred to the heated object through the generated infrared radiation; Each...

Embodiment 2

[0024] figure 1 It is an infrared burner equipped with a porous honeycomb metal combustion plate. It is composed of an air intake injection system, a combustion chamber shell, an air distribution device, and a metal honeycomb infrared combustion plate. Fuel and air (referred to as gas) are mixed and enter the gas mixing chamber 3 of the burner from the gas and air inlet 4. The gas is evenly distributed in the gas mixing chamber, and then reaches the fire hole through many pipes on the carrier. At this time, the ignition The final gas undergoes complete catalytic combustion on the surface of the high-temperature-resistant catalytic coating, and the surface of the fire hole heats up rapidly due to the huge energy released by the catalytic combustion, producing a bright and uniform infrared combustion effect. In this way, the heat accumulated on the surface of the fire hole It continuously radiates outwards in the form of infrared rays, giving full play to the excellent performan...

Embodiment 3

[0027] Catalyst mineralization coating: by weight percentage, 5% magnesium oxide, 25% mixed water glass, 15% pseudoboehmite, 3% nickel oxide, 6% cobalt oxide, 5% mixed rare earth oxide, 15% color masterbatch Material, 26% purified water.

[0028] Step A: The metal carrier must be pretreated: remove oil, dust, burrs and other impurities attached to the surface of the carrier channel during the manufacturing process, and then perform surface oxidation treatment at 300 ° C for 3 hours;

[0029] Step B: Along the direction of the fire hole channel of the metal carrier, apply the catalyst mineralization coating on the pretreated metal carrier fire hole channel, and then dry and sinter mineralization at 200°C to obtain a firm adhesion A porous honeycomb metal combustion plate is prepared on the metal carrier channel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com