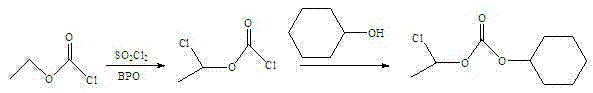

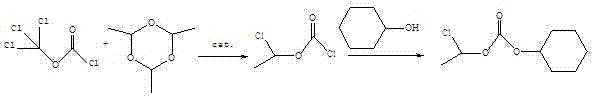

Preparation method of 1-chloroethyl cyclohexyl propyl carbonate

A technology of cyclohexyl propyl carbonate and chloroethyl, applied in the field of preparation of 1-chloroethyl cyclohexyl propyl carbonate, can solve the problems of toxic gas leakage, high risk, uneconomical, etc. Small, low-cost, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) In a 1000ml reaction bottle, put 198g of trichloromethyl chloroformate, start stirring, when the temperature of trichloromethyl chloroformate drops to -10~0℃, add 2g of triethylamine, dropwise add 88g of paraldehyde , the dropping process takes 4 hours. After the dropping is completed, continue to stir the reaction for 2h, then add 206g of triethylamine, and add 200g of cyclohexanol dropwise after the temperature after mixing is 19°C. After the dropwise addition, continue to stir and react for 3h .

[0028] After the reaction was finished, 100 g of water was added, and the organic phase was separated to be the crude product of 1-chloroethylcyclohexylpropyl carbonate.

[0029] (2) Put the crude product of 1-chloroethylcyclohexylpropyl carbonate into the rectification reaction bottle, control the temperature in the bottle below 130°C, and conduct vacuum distillation to obtain 1-chloroethylcyclohexylpropyl Carbonic acid ester 380g, yield is 92%, and purity is greater ...

Embodiment 2

[0031] (1) In a 1000ml reaction bottle, put 238g of trichloromethyl chloroformate, start stirring, cool down to -10~0℃, add 2.4g of pyridine, dropwise add 106g of paraldehyde, the dropwise addition process takes 6 hours, dropwise After completion, continue stirring for 2 hours, add 247 g of pyridine, and add 240 g of cyclohexanol dropwise after the temperature after mixing is below 20°C, and continue stirring for 3 hours after the dropwise addition is complete.

[0032] After the reaction was completed, 120 g of water was added, and the organic phase was separated to be crude 1-chloroethylcyclohexylpropyl carbonate.

[0033] (2) Put the crude product of 1-chloroethylcyclohexylpropyl carbonate into the rectification reaction bottle, control the temperature in the bottle below 130°C, and conduct vacuum distillation to obtain 1-chloroethylcyclohexyl Propyl carbonate 461g, the yield is 93%, and the purity is greater than 99.5%.

Embodiment 3

[0035] (1) In a 1000ml reaction bottle, put 218g of trichloromethyl chloroformate, start stirring, cool down to -10~0℃, add 2.4g of N,N-dimethylaniline, dropwise add 116.6g of paraldehyde, drop The process takes 6 hours. After the dropwise addition, continue to stir for 2 hours, add 272g of N,N-dimethylaniline, after the temperature after mixing is below 20°C, add 220g of cyclohexanol dropwise, after the dropwise addition, continue to stir for 3h .

[0036] After the reaction was completed, 110 g of water was added, and the organic phase was separated to be crude 1-chloroethylcyclohexylpropyl carbonate.

[0037] (2) Put the crude product of 1-chloroethylcyclohexylpropyl carbonate into the rectification reaction bottle, control the temperature in the bottle below 130°C, and conduct vacuum distillation to obtain 1-chloroethylcyclohexyl Propyl carbonate 420g, the yield is 92.5%, and the purity is greater than 99.5%.

[0038] In the present invention, when step 1) uses one of tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com