Oxygen-nitrogen glass material with high elastic energy dissipation capacity and preparation method thereof

A technology of oxygen nitrogen glass and capacity, applied in the field of light transparent armor materials, can solve the problems of size and light transmittance limitations, high requirements, size and transparency limitations, etc., to meet the requirements of industrial production, strong energy dissipation ability, The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

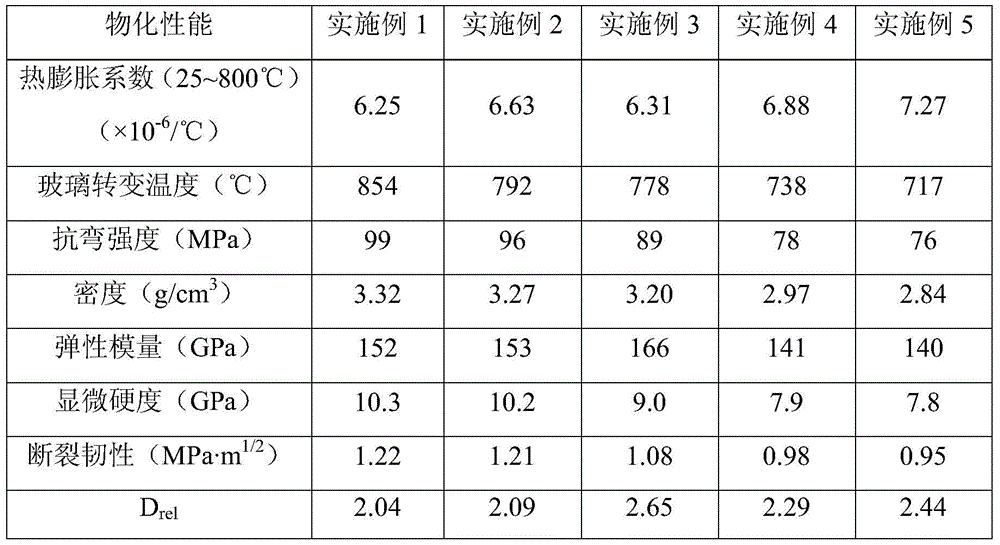

Embodiment 1

[0027] Formulation 1: Si 3 N 4 : 7.23mol%, Y 2 o 3 : 14.46mol%, SiO 2 : 51.80mol%, Al 2 o 3 : 12.05 mol%, ZnO: 14.46 mol%.

[0028] (1) Preparation of the mixture: according to the design composition of the specific oxynitride glass, convert it into a mass percentage, accurately weigh the corresponding raw materials of each composition, weigh and ball-mill the powdery raw materials, mix them, and pass through an 80-mesh sieve;

[0029] (2) At room temperature, first vacuumize the furnace, then pour nitrogen into the resistance furnace, and then evacuate again, repeat this 3 times to remove the air in the furnace, and finally maintain the nitrogen pressure in the furnace at 0.1MPa ;

[0030] (3) Put the batch material into a quartz crucible or a corundum crucible, put it in a graphite crucible, cover with a graphite cover, and heat up to 1630 at a heating rate of 5°C / min in a silicon-molybdenum resistance furnace with good sealing. ℃, keep warm for 2 hours;

[0031] (4...

Embodiment 2

[0033] Recipe 2: Si 3 N 4 : 7.23mol%, Y 2 o 3 : 14.46mol%, SiO 2 : 51.80mol%, Al 2 o 3 : 12.05 mol%, SrO: 14.46 mol%.

[0034] (1) Preparation of the mixture: according to the design composition of the specific oxynitride glass, convert it into a mass percentage, accurately weigh the corresponding raw materials of each composition, weigh and ball-mill the powdery raw materials, mix them, and pass through an 80-mesh sieve;

[0035] (2) At room temperature, first vacuumize the furnace, then pour nitrogen into the resistance furnace, and then evacuate again, repeat this 3 times to remove the air in the furnace, and finally maintain the nitrogen pressure in the furnace at 0.1MPa ;

[0036] (3) Put the batch material into a quartz crucible or a corundum crucible, put it in a graphite crucible, cover with a graphite cover, and heat up to 1600 ℃ at a heating rate of 5°C / min in a silicon-molybdenum resistance furnace with good sealing. ℃, keep warm for 2 hours;

[0037] (4) Aft...

Embodiment 3

[0039] Recipe 3: Si 3 N 4 : 6.59mol%, Y 2 o 3 : 8.79mol%, SiO 2 : 47.25mol%, Al 2 o 3 : 10.99 mol%, SrO: 13.19 mol%, ZnO: 13.19 mol%.

[0040] (1) Preparation of the mixture: according to the design composition of the specific oxynitride glass, convert it into a mass percentage, accurately weigh the corresponding raw materials of each composition, weigh and ball-mill the powdery raw materials, mix them, and pass through an 80-mesh sieve;

[0041] (2) At room temperature, first vacuumize the furnace, then pour nitrogen into the resistance furnace, and then evacuate again, repeat this 3 times to remove the air in the furnace, and finally maintain the nitrogen pressure in the furnace at 0.1MPa ;

[0042] (3) Put the batch material into a quartz crucible or a corundum crucible, put it in a graphite crucible, cover with a graphite cover, and heat up to 1600 ℃ at a heating rate of 8°C / min in a silicon-molybdenum resistance furnace with good sealing. ℃, keep warm for 2.4 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com