Silver-modified carbon nitride composite photocatalytic material and preparation method thereof

A technology of composite photocatalysis and carbon nitride, which is applied in the direction of chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of high cost and poor purification effect, and achieve the purpose of inhibiting recombination and improving photocatalysis efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

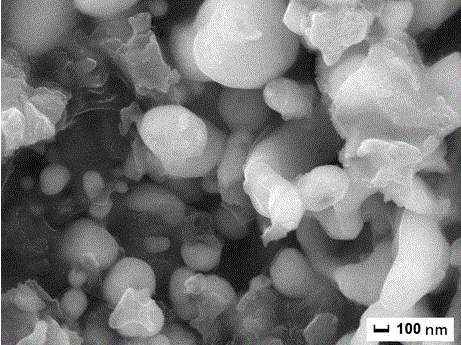

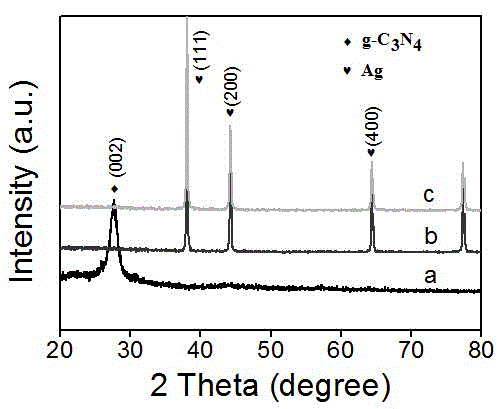

[0027] Dissolve 10mmol (0.84 g) of dicyandiamide in 40 ml of deionized water and sonicate for 30 minutes to obtain a dispersion of dicyandiamide; weigh 10 mmol (1.69 g) of silver nitrate and dissolve it in 40 ml of deionized water, stir for 10 minutes, Obtaining a silver nitrate solution; adding the above-mentioned silver nitrate solution dropwise to the dicyandiamide dispersion under the condition of magnetic stirring to form a mixed solution, and slowly stirring the mixed solution for 6 hours after the dropwise addition to obtain a mixed precursor solution; The obtained mixed precursor solution was repeatedly washed with absolute ethanol and deionized water for 3 times, and then dried in vacuum at 50 degrees. Then, the product was put into a suitable crucible and covered, and then placed in a high-temperature atmosphere furnace. Under the condition of nitrogen protection, the sample In the high-temperature atmosphere furnace, the temperature was raised from room temperature t...

Embodiment 2

[0029] Dissolve 10 mmol (0.84 g) of dicyandiamide in 40 ml of deionized water and sonicate for 30 minutes to obtain a dispersion of dicyandiamide; weigh 20 mmol (3.38 g) of silver nitrate and dissolve it in 40 ml of deionized water, stir for 10 minutes, Obtaining a silver nitrate solution; adding the above-mentioned silver nitrate solution dropwise to the dicyandiamide dispersion under the condition of magnetic stirring to form a mixed solution, and slowly stirring the mixed solution for 6 hours after the dropwise addition to obtain a mixed precursor solution; The obtained mixed precursor solution was repeatedly washed with absolute ethanol and deionized water for 3 times, and then dried in vacuum at 50 degrees; then the product was put into a suitable crucible and covered, and then placed in a high-temperature atmosphere furnace. Under the condition of nitrogen protection, the sample In the high-temperature atmosphere furnace, the temperature was raised from room temperature t...

Embodiment 3

[0031] Dissolve 10mmol (0.84 g) of dicyandiamide in 40 ml of DMSO and sonicate for 30 minutes to obtain a dispersion of dicyandiamide; weigh 10 mmol (1.69 g) of silver nitrate and dissolve it in 40 ml of deionized water, stir for 10 minutes to obtain Silver nitrate solution; the above-mentioned silver nitrate solution is added dropwise to the dicyandiamide dispersion liquid under the condition of magnetic stirring to form a mixed solution, and after the dropwise addition, the mixed solution is slowly stirred for 6 hours to obtain a mixed precursor solution; the obtained The mixed precursor solution was repeatedly washed with absolute ethanol and deionized water for 3 times, and then dried in vacuum at 50 degrees; then the product was put into a suitable crucible and covered, and then placed in a high-temperature atmosphere furnace. The high-temperature atmosphere furnace rises from room temperature to 550 degrees at a constant speed for 4 hours, heat-preserves and sinters for 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com