High-elasticity PHA porous fiber material and preparing method thereof

A polyhydroxyalkanoate and porous fiber technology, applied in fiber treatment, spinning solution preparation, non-woven fabrics, etc., can solve the problems of low tensile strength and elongation rate, and no research on the influence of tensile mechanical properties , to achieve the effect of fine fiber diameter, improved electrospinning yield, and high electrospinning yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh 4g of P3HB4HB, slowly add the weighed P3HB4HB into 46g of mixed solvent of chloroform and chloroform, the mass fraction of acetone is 1%, under the condition of magnetic stirring for about 4 hours, the polymer concentration can be obtained as 8wt %The solution. Then transfer the polymer solution to a 10ml glass syringe and place it in an electrospinning device. By adjusting the voltage to 10kV, the extrusion rate is 3ml / h, and the distance from the needle to the receiving device is 14cm, fibers can be obtained under this condition Fiber membrane with uniform diameter distribution and good shape.

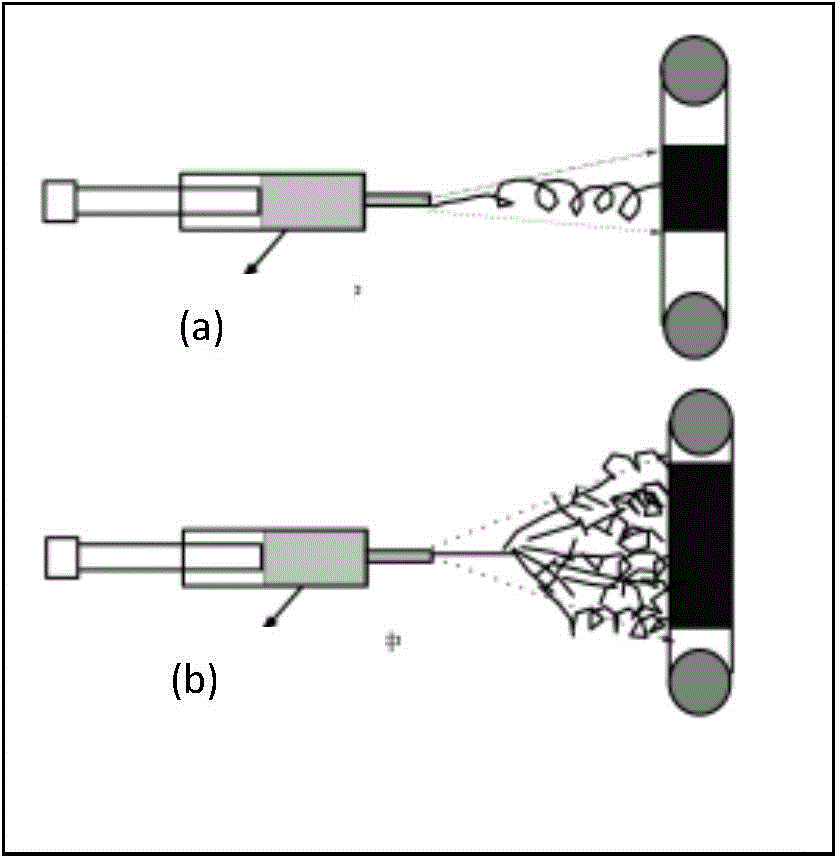

[0026] See attached figure 1 (a), the results of the scanning electron microscope (SEM) of the sample prepared by the technical scheme of this embodiment show that the prepared fibrous scaffold has a good shape and a uniform diameter distribution (5.4±0.5 μm).

Embodiment 2

[0028] Weigh 4g of P3HB4HB, and slowly add the weighed P3HB4HB into the mixed solvent prepared in advance, and the mass fractions of acetone are 25%, 35% and 50% respectively. Under the condition of magnetic stirring for about 4 hours, a solution with a polymer concentration of 8wt% can be obtained. Then transfer the polymer solution to a 10ml glass syringe and place it in an electrospinning device. By adjusting the voltage to 10kV, the extrusion rate is 3ml / h, and the distance from the needle to the receiving device is 14cm, fibers can be obtained under this condition Fiber membrane with uniform diameter distribution and good shape.

[0029] See attached figure 1 (b-d), the scanning electron microscope (SEM) results of the sample prepared by the technical scheme of this embodiment show that the prepared fiber scaffold has a good shape and a uniform diameter distribution, and the fiber diameter decreases with the increase of the mass fraction of acetone. When the mass fracti...

Embodiment 3

[0033] Weigh 4g of P3HB4HB, slowly add the weighed P3HB4HB into 46g of acetone solvent, and under the condition of magnetic stirring for about 4 hours, a solution with a polymer concentration of 8wt% can be obtained. Then transfer the polymer solution to a 10ml glass syringe and place it in an electrospinning device. By adjusting the voltage to 10kV, the extrusion rate is 3ml / h, and the distance from the needle to the receiving device is 14cm. Under this condition, the morphology cannot be obtained. good fiber.

[0034] See attached figure 1 (e), the result of the scanning electron microscope (SEM) of the sample prepared by the technical scheme of this embodiment shows that the prepared fiber contains a large number of beads and has poor fiber formation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Dielectric constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com