High temperature abrasion resistant guide plate and preparation method thereof

A kind of guide plate and high temperature resistance technology, applied in the direction of guiding/positioning/aligning device, etc., can solve the problem of poor process stability of composite wear-resistant guide plate, alloy powder core rod unable to form reinforcement phase, alloy powder core rod collapse and other problems, to achieve the effect of large-scale production, not easy to crack and peel, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

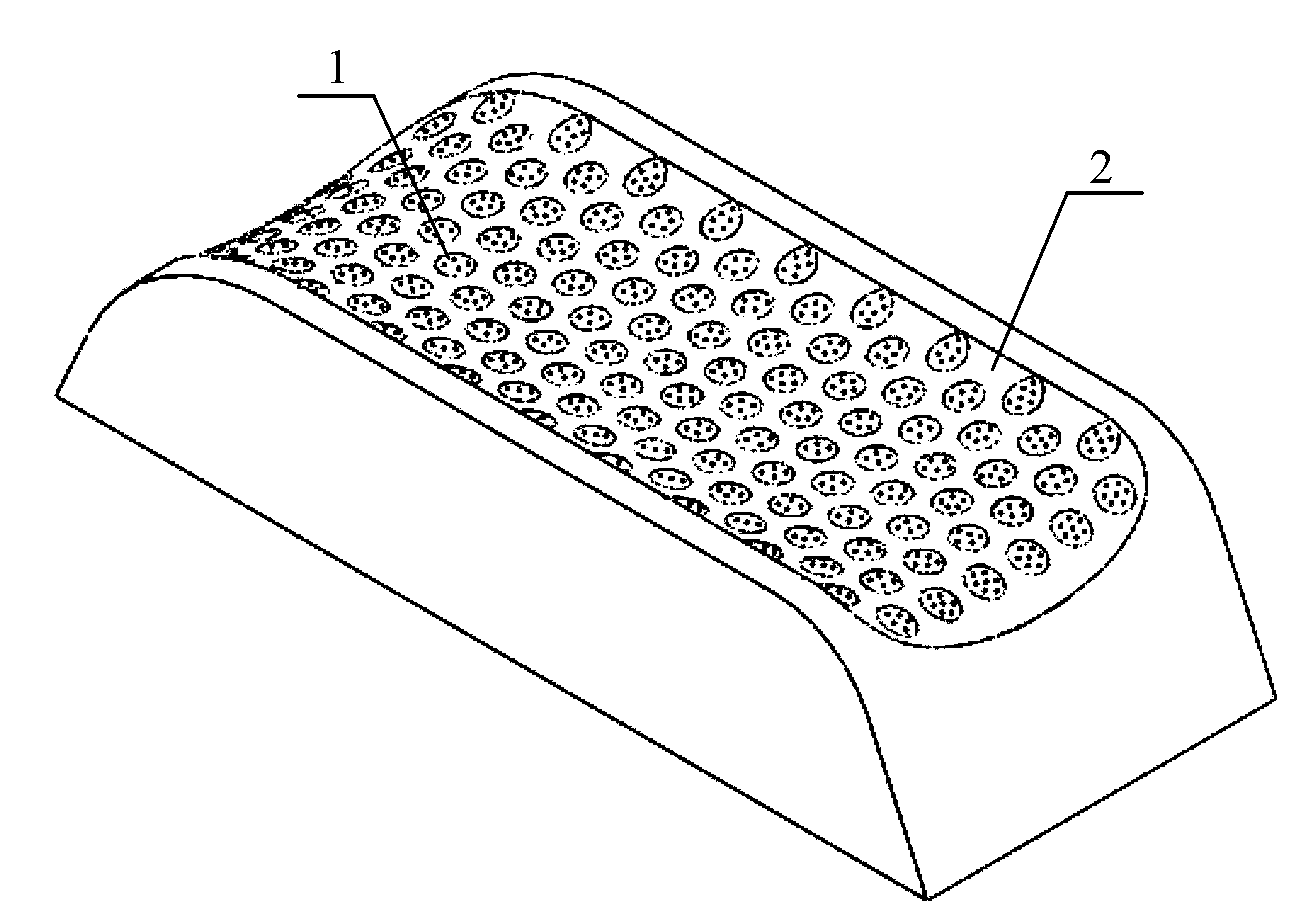

[0028] Such as figure 1 As shown, a high-temperature wear-resistant guide plate is composed of WC granular rod-shaped reinforcement phase 1 and high-chromium-nickel alloy matrix 2. The WC granular rod-shaped reinforcement phase 1 is evenly distributed on the surface layer of high-chromium-nickel alloy matrix 2. A "honeycomb" structure is formed on the top, and the volume fraction of the WC granular rod-shaped reinforcement phase 1 accounting for the surface layer of the high-chromium-nickel alloy matrix 2 is 40%;

[0029] The composition weight percent of the high-chromium-nickel alloy substrate 2 is: 1.0%C, 6.0%Ni, 18%Cr, 0.6%Si, 0.8%Mn, <0.05%S, <0.05%P, and the balance is Fe;

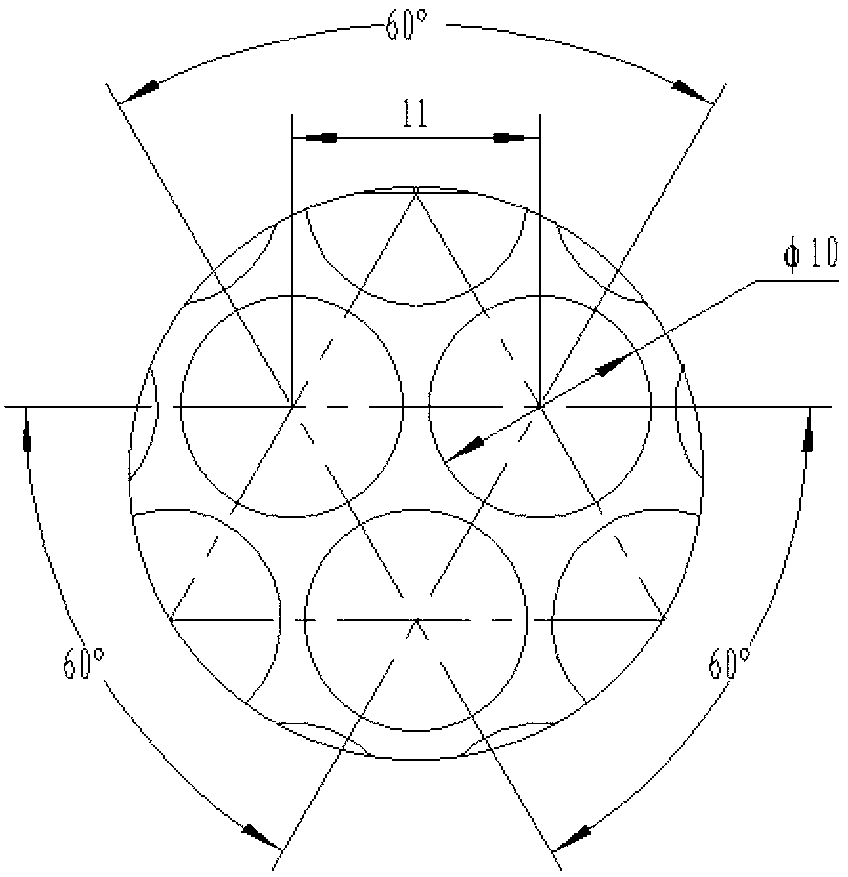

[0030] The WC granular rod-shaped reinforcement phase 1 is composed of WC particles and Ni-based solder. The WC particles account for 25% of the volume fraction of the WC granular rod-shaped reinforced phase 1. The WC particle size is 100 mesh, and the Ni-based solder has a particle size of 200 mesh....

Embodiment 2

[0040] Such as figure 1 As shown, a high-temperature wear-resistant guide plate is composed of WC granular rod-shaped reinforcement phase 1 and high-chromium-nickel alloy matrix 2. The WC granular rod-shaped reinforcement phase 1 is evenly distributed on the surface layer of high-chromium-nickel alloy matrix 2. A "honeycomb" structure is formed on the top, and the volume fraction of the WC granular rod-shaped reinforcement phase 1 accounting for the surface layer of the high-chromium-nickel alloy matrix 2 is 40%;

[0041] The composition weight percent of the high-chromium-nickel alloy substrate 2 is: 1.6%C, 8%Ni, 24%Cr, 0.8%Si, 1.0%Mn, <0.05%S, <0.05%P, and the balance is Fe;

[0042] The WC particle rod-shaped reinforcing phase 1 is composed of WC particles and Ni-based solder. The WC particle accounts for 35% of the volume fraction of the WC particle rod-shaped reinforcing phase 1. The WC particle size is 200 mesh, and the Ni-based solder particle size is 400 mesh. The com...

Embodiment 3

[0052] Such as figure 1 As shown, a high-temperature wear-resistant guide plate is composed of WC granular rod-shaped reinforcement phase 1 and high-chromium-nickel alloy matrix 2. The WC granular rod-shaped reinforcement phase 1 is evenly distributed on the surface layer of high-chromium-nickel alloy matrix 2. A "honeycomb" structure is formed on the top, and the volume fraction of the WC granular rod-shaped reinforcing phase 1 accounting for the surface layer of the high-chromium-nickel alloy matrix 2 is 75%;

[0053] The composition weight percent of the high-chromium-nickel alloy substrate 2 is: 2.0%C, 10%Ni, 28%Cr, 1.0%Si, 1.2%Mn, <0.05%S, <0.05%P, and the balance is Fe;

[0054] The WC particle rod-shaped reinforcing phase 1 is composed of WC particles and Ni-based solder. The WC particles account for 50% of the volume fraction of the WC particle rod-shaped reinforcing phase 1. The composition weight percentage of solder is: 14%Cr, 3.5%B, 5.0%Si, 5.0%Fe, 0.2%C, the bala...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com