Process for preparing Mo2FeB2-based metal ceramic

A preparation process, mo2feb2 technology, applied in the field of cermet preparation, can solve problems such as unreachable, increase in preparation cycle, and unoptimized performance, and achieve the effect of simple process, high relative density and good mechanical performance index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] First, the raw material is Fe with a purity of 99.9% and a particle size of 100 μm 2 B powder and Mo powder with a purity of 99.99% and a particle size of 100 μm, the weight ratio is controlled at 0.25:0.75, and anhydrous ethanol with a weight of 0.5% of the mixed powder is added as a process control agent, weighed and loaded into a stainless steel ball mill tank and pumped. Vacuum, the degree of vacuum is 10 -1 Pa.

[0016] Then, put the ball mill jar into the ball mill and turn it on, after 5 hours of ball milling time, the jar body is cooled to room temperature, and the Fe 2 The mixed powder of B and Mo was filled into a metal mold, and molded at 150 MPa.

[0017] Finally, put the molded green body into a graphite mold and carry out pressureless sintering in a vacuum sintering furnace. The vacuum degree during sintering is 10 -2 Pa; the heating rate is 10°C / s; the sintering temperature is: 1250°C (no need for heat preservation treatment), after the sintering is co...

Embodiment 2

[0019] Technological process is basically the same as embodiment 1, but process parameter is different: Fe 2 The particle size of B powder is 150 μm; the particle size of Mo powder is 50 μm, and the weight ratio is controlled at 0.5:0.5.

[0020] Ball milling time is 25 hours; molding pressure is 200MPa.

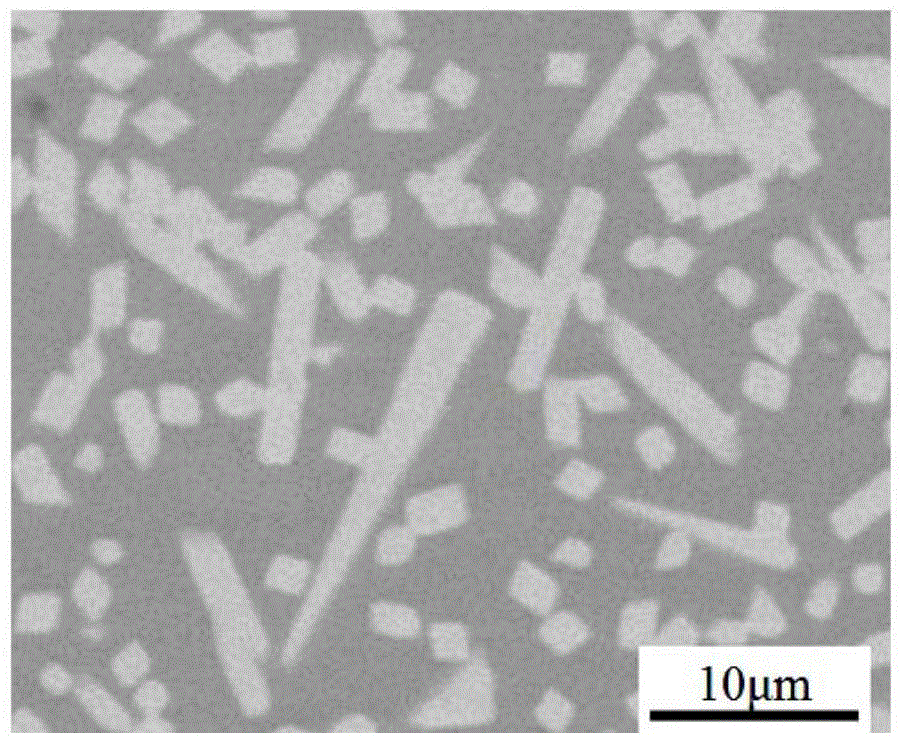

[0021] The pressureless sintering vacuum is 10 -1 Pa; heating rate is 5°C / s; sintering temperature is 1350°C. Mo prepared in this example 2 FeB 2 The density of the base cermet is 99.1%, the three-point bending strength is 2000MPa, and the hardness is 87.3HRA. The optical micrograph of its microstructure is as figure 1 As shown (corroding 5 seconds with 5% nitric acid alcohol), it can be seen from the figure that Mo 2 FeB 2 The base cermet has a dense structure, most Mo 2 FeB 2 It is distributed in a square shape block, so it has a high comprehensive mechanical performance index.

Embodiment 3

[0023] Technological process is basically the same as embodiment 1, but process parameter is different: Fe 2 The particle size of B powder is 50 μm; the particle size of Mo powder is 100 μm, and the weight ratio is controlled at 0.4:0.6.

[0024] Ball milling time is 15 hours; molding pressure is 300MPa.

[0025] The pressureless sintering vacuum is 10 -3 Pa; heating rate is 2°C / s; sintering temperature is 1300°C. Mo prepared in this example 2 FeB 2 The density of the base cermet is 98.4%, the three-point bending strength is 1691MPa, and the hardness is 89.0HRA.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com