Chromium-aluminum alloy target and manufacturing method thereof

A technology of chrome-aluminum alloy and target material, which is applied in the field of target material manufacturing, can solve the problem that the coating material is difficult to meet, and achieve the effect of controlling the oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

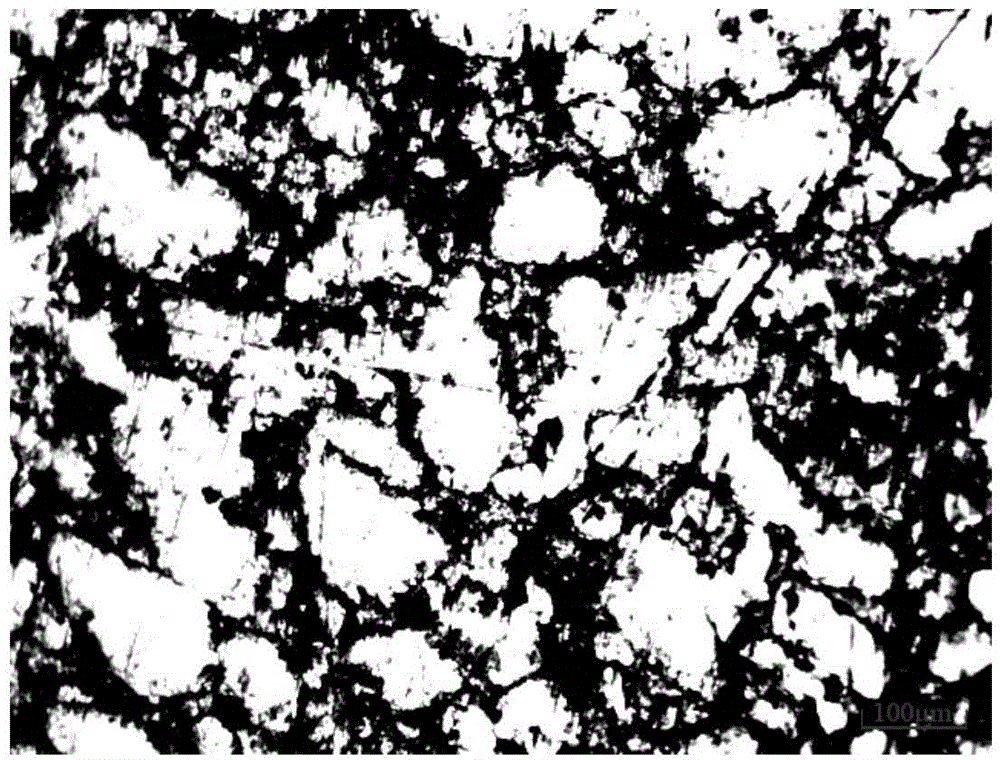

Embodiment 1

[0036] (1) select the raw material that oxygen content is all lower than 2000ppm, purity is greater than 99.9%, particle size is-100 order, carry out mixing according to proportion, Cr is 22at%, Al is 63at%, Ti is 12at%, W is 2at%, Y is 1at%;

[0037] (2) Put the mixed material into the ladle, and the argon arc welding will not leak;

[0038] (3) The ladle sleeve is placed in a well-type heat treatment furnace for degassing treatment, the degassing treatment temperature is 220 ° C, and the degassing treatment time is 8 hours;

[0039] (4) weld the ladle cover that has been degassed;

[0040] (5) Put the degassed ladle sleeve in the hot isostatic pressing equipment for hot isostatic pressing treatment. The hot isostatic pressing treatment conditions are a temperature of 550 ° C, a heating rate of 60 ° C / hour, and a temperature homogenization time of 2 hours, the holding time is 3 hours, and the cooling rate is 75°C / hour.

[0041] (6) Take it out when the temperature drops ...

Embodiment 2

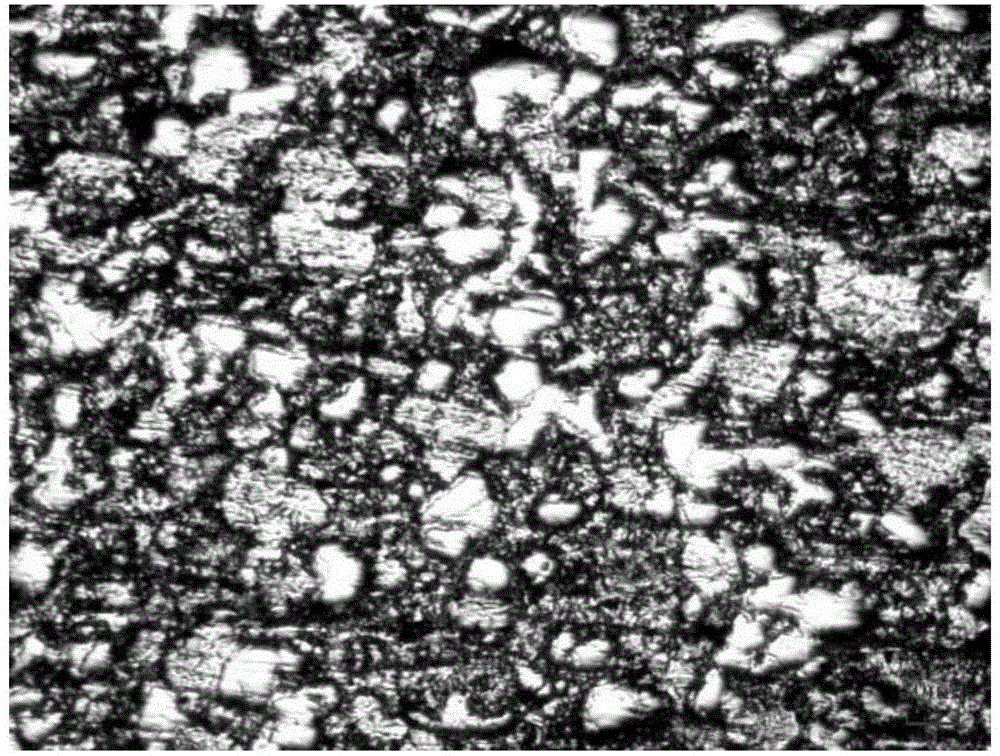

[0045] (1) select the raw material that oxygen content is all lower than 2000ppm, and purity is greater than 99.9%, and particle size is-200 order, carries out mixing according to proportion, and Cr is 20at%, Al is 65at%, Si is 13at%, V is 1at%, Ce is 1at%;

[0046] (2) Put the mixed material into the ladle, and the argon arc welding will not leak;

[0047] (3) The ladle sleeve is placed in a well-type heat treatment furnace for degassing treatment, the degassing treatment temperature is 300 ° C, and the degassing treatment time is 4 hours;

[0048] (4) weld the ladle cover that has been degassed;

[0049] (5) Put the degassed ladle sleeve in the hot isostatic pressing equipment for hot isostatic pressing treatment. The hot isostatic pressing treatment conditions are a temperature of 520 ° C, a heating rate of 80 ° C / hour, and a temperature homogenization time of 1 hours, the holding time is 4 hours, and the cooling rate is 50°C / hour.

[0050] (6) Take it out when the tempe...

Embodiment 3

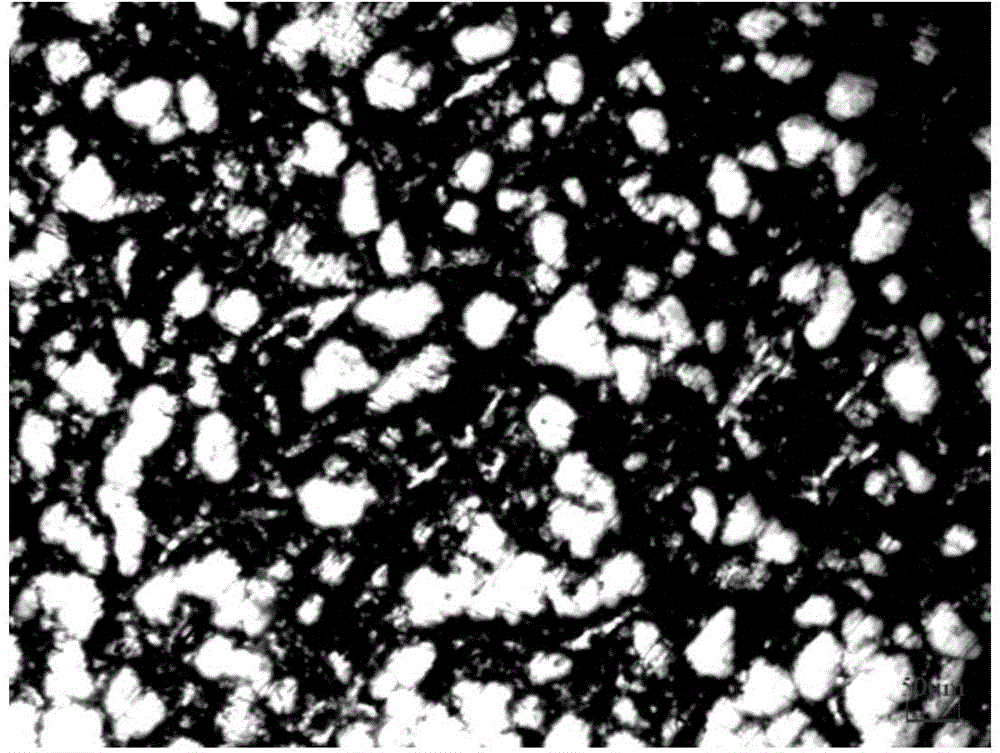

[0054] (1) select the raw material whose oxygen content is all lower than 2000ppm, the purity is greater than 99.9%, the particle size is -400 mesh, mix according to the proportion, Cr is 30at%, Al is 64at%, W is 2at%, B is 3at%, La is 1 at %;

[0055] (2) Put the mixed material into the ladle, and the argon arc welding will not leak;

[0056] (3) The ladle sleeve is placed in a well-type heat treatment furnace for degassing treatment, the degassing treatment temperature is 299 ° C, and the degassing treatment time is 12 hours;

[0057] (4) weld the ladle cover that has been degassed;

[0058] (5) Put the degassed steel ladle in the hot isostatic pressing equipment for hot isostatic pressing treatment. The hot isostatic pressing treatment conditions are a temperature of 540 ° C, a heating rate of 80 ° C / hour, and a temperature homogenization time of 1 hours, the holding time is 5 hours, and the cooling rate is 50°C / hour.

[0059] (6) Take it out when the temperature drops...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com