Nanocarbon material-based high-performance heat conducting material and preparation method thereof

A technology of thermally conductive materials and carbon nanomaterials, which is applied in the field of high-performance thermally conductive material preparation, can solve the problems of low thermal conductivity, high filling amount of thermally conductive fillers, and high manufacturing costs, so as to improve thermal conductivity, thermal conductivity, and thermal conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

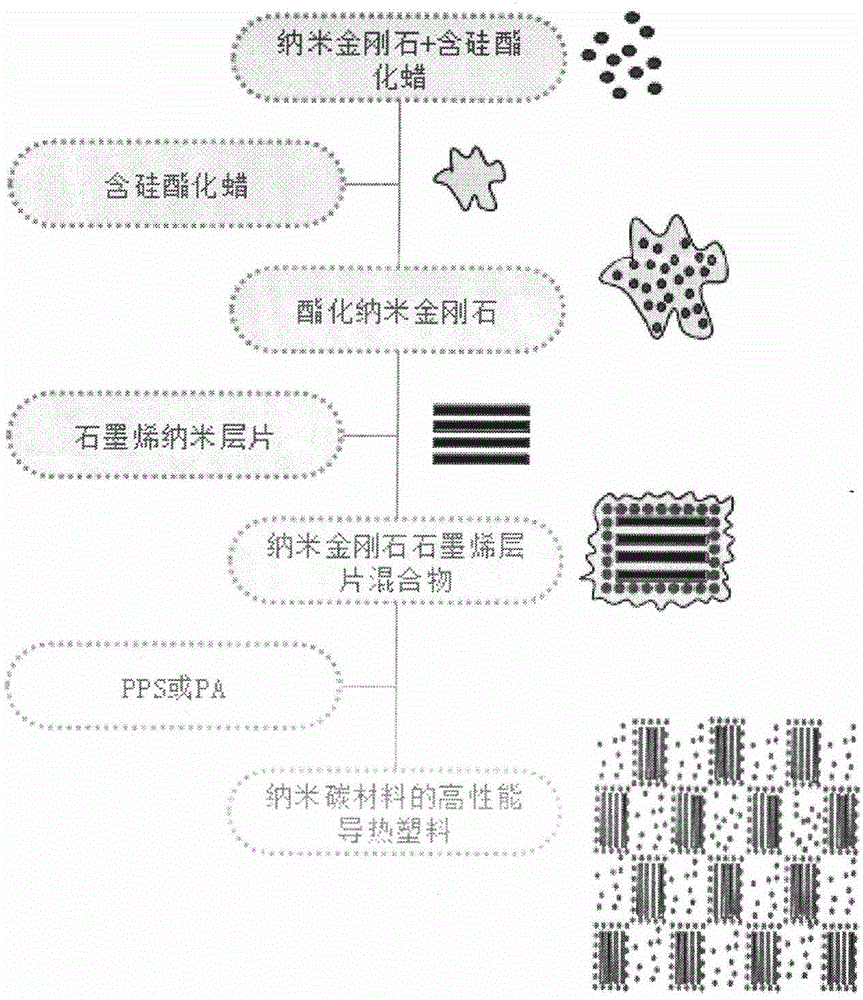

Method used

Image

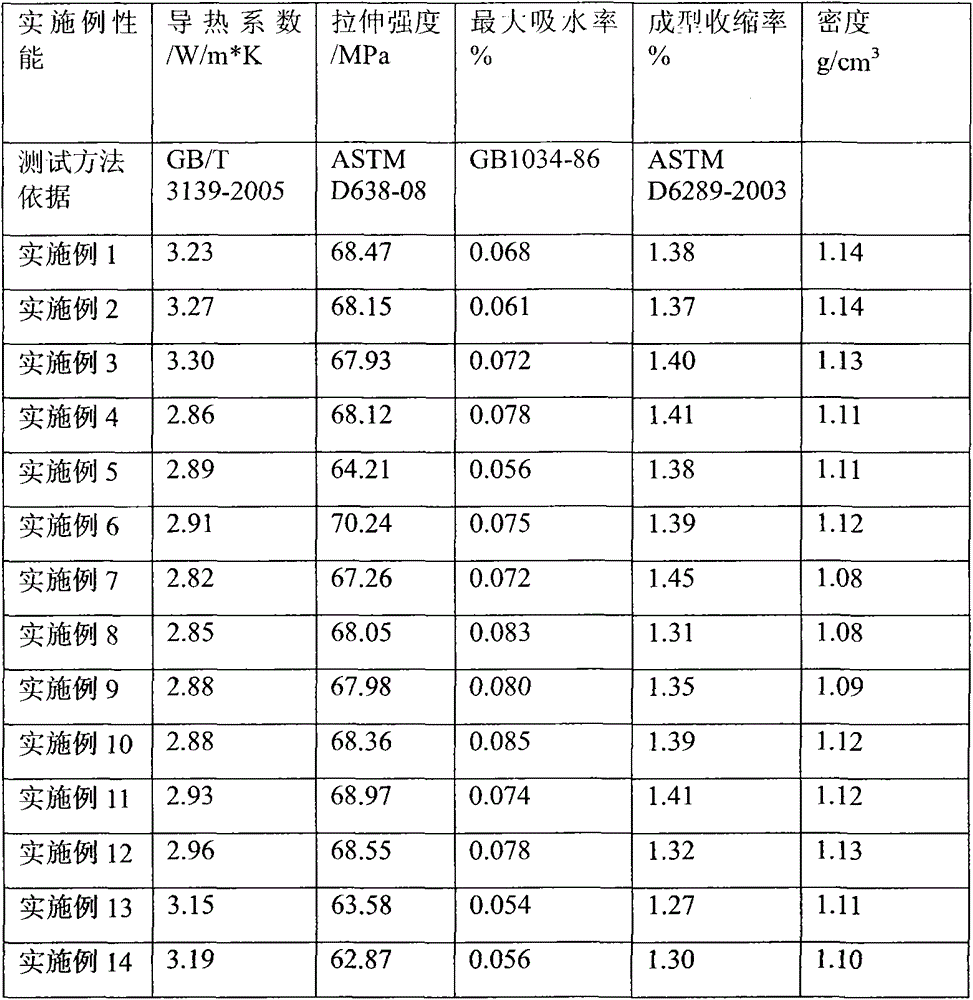

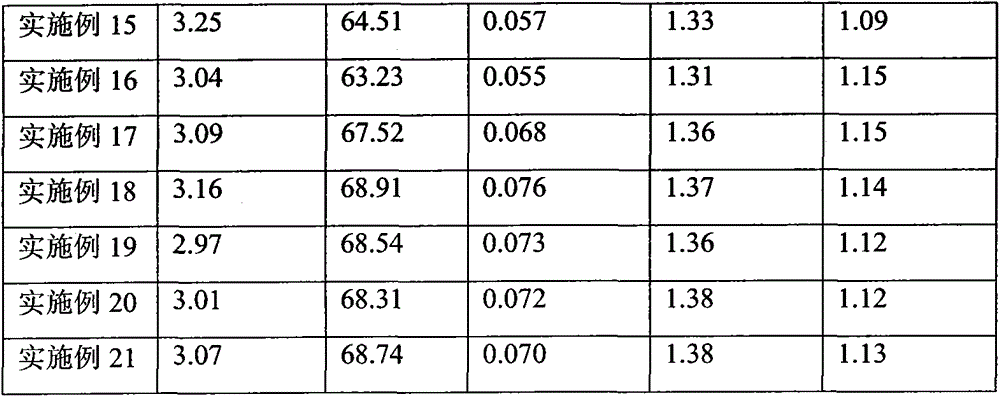

Examples

Embodiment 1

[0023] (1) Surface treatment of thermally conductive fillers: use a plasma activator (plasma cleaning experimental equipment EPT-02, produced by Suzhou Opus Plasma Technology Co., Ltd.; the same below.) to activate nano-diamonds by irradiation to clean the surface and activate at the same time Its surface site; use acetone to disperse the silane coupling agent and dry process the graphene nanosheet for 1 hour;

[0024] (2) Preparation of mixed thermally conductive filler: 10g of silicon-containing esterified wax and 10g of nano-diamonds are mixed in a high-speed mixer, and then the mixture is mixed with 5g of graphene nanosheets in a high-speed mixer. Mix high thermal conductivity filler.

[0025] (3) Preparation of high thermal conductivity resin: Premix 75g of nylon-66 resin and 25g of high thermal conductivity filler prepared in the above steps, and pass through a twin-screw extruder (model SHJ-36, Nanjing Jieya Extrusion Co., Ltd.) at 260°C Equipment Co., Ltd.; the same b...

Embodiment 2

[0029] (1) Surface treatment of thermally conductive fillers: use a plasma activator (plasma cleaning experimental equipment EPT-02, produced by Suzhou Opus Plasma Technology Co., Ltd.; the same below.) to activate nano-diamonds by irradiation to clean the surface and activate at the same time Its surface site; use acetone to disperse silane coupling agent and dry process graphene nanosheet for 1.5 hours;

[0030] (2) Preparation of mixed thermally conductive filler: 10g of silicon-containing esterified wax and 9g of nano-diamonds are mixed in a high-speed mixer, and then the mixture is mixed with 6g of graphene nanosheets in a high-speed mixer. Mix high thermal conductivity filler.

[0031] (3) Preparation of high thermal conductivity resin: Premix 75g of nylon-66 resin and 25g of high thermal conductivity filler prepared in the above steps, and pass through a twin-screw extruder (model SHJ-36, Nanjing Jieya Extrusion Co., Ltd.) at 260°C Equipment Co., Ltd.; the same below.)...

Embodiment 3

[0035] (1) Surface treatment of thermally conductive fillers: use a plasma activator (plasma cleaning experimental equipment EPT-02, produced by Suzhou Opus Plasma Technology Co., Ltd.; the same below.) to activate nano-diamonds by irradiation to clean the surface and activate at the same time Its surface site; use acetone to disperse the silane coupling agent and dry process the graphene nanosheet for 2 hours;

[0036] (2) Preparation of mixed thermally conductive filler: 10g of silicon-containing esterified wax and 8g of nano-diamonds are mixed in a high-speed mixer, and then the mixture is mixed with 7g of graphene nanosheets in a high-speed mixer. Mix high thermal conductivity filler.

[0037] (3) Preparation of high thermal conductivity resin: Premix 70g of nylon-66 resin and 25g of high thermal conductivity filler prepared in the above steps, and pass through a twin-screw extruder (model SHJ-36, Nanjing Jieya Extrusion Co., Ltd.) at 260°C Equipment Co., Ltd.; the same b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com