ASA plastic-wood material and preparation method thereof

A technology of wood-plastic material and wood powder, applied in the field of ASA wood-plastic material and its preparation, can solve the problems of unsuitability for building exterior walls, cumbersome production process, high product rejection rate, and achieve improved bonding performance and interface compatibility, The effect of reducing product weight and ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

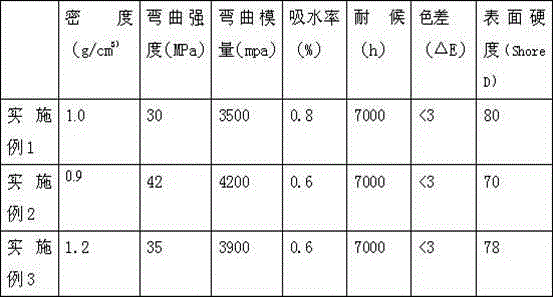

Examples

Embodiment 1

[0029] a. Take by weighing 30g of ammonium stearate, 40g of fatty acid, 5g of sodium hydroxide, 1g of hydrogen peroxide, and 10g of polyethylene glycol, and mix the above to obtain a processing aid for wood powder, take by weighing 1000g of wood powder, and mix the processing aid Add wood flour and stir evenly to obtain treated wood flour;

[0030] b. Weigh 200g of AS resin powder, 400g of ASA high rubber powder, 100g of wollastonite powder, 1010 3g of hindered phenols; 1g of ultraviolet absorber UV531; Mix for 5 minutes, add the mixed material into a parallel twin-screw extruder at a temperature of 170-200° C. to extrude and pelletize to obtain ASA pellets;

[0031] c. Take 720g of ASA particles prepared in step b and 240g of wood powder prepared in step a, then weigh 20g of compatibilizer SEBS-g-MAH, 5g of foaming agent AC, and 20g of lubricant calcium stearate, and put them together Put it into a high-speed mixer at 80°C and mix for 5 minutes, then add it to a conical twin...

Embodiment 2

[0033] a, take by weighing 40g of ammonium stearate, 50g of fatty acid, 8g of magnesium hydroxide, 0.8g of water, polyethylene glycol 20g, mix above and make the processing aid of wood powder, take by weighing 1500g wood powder, process aid The agent is added into the wood powder and stirred evenly to obtain the treated wood powder;

[0034] b. Weigh 300g of AS resin powder, 500g of ASA high rubber powder, 200g of wollastonite powder, 168 3g of phosphite; 1g of ultraviolet absorber UV531; Mix for 5 minutes at 100°C, and add the mixed material into a parallel twin-screw extruder at a temperature of 170-200°C to extrude and granulate to obtain ASA granules;

[0035] c. Take 800g of ASA particles prepared in step b and 160g of wood powder prepared in step a, then weigh 20g of compatibilizer SEBS-g-MAH, 6g of foaming agent AC, and 20g of lubricant calcium stearate, and put them together Put it into a high-speed mixer at 80°C and mix for 5 minutes, then add it to a conical twin-sc...

Embodiment 3

[0037] a, take by weighing 20g of ammonium stearate, 35g of fatty acid, 5g of calcium oxide, 1.2g of acetic acid, polyethylene glycol 20g, mix the above to make the processing aid of wood powder, take by weighing 900g of wood powder, make the processing aid Add wood flour and stir evenly to obtain treated wood flour;

[0038] b. Weigh 400g of AS resin powder, 600g of ASA high rubber powder, 300g of wollastonite powder, 1010 3g of hindered phenols; 1g of ultraviolet absorber UV531; Mix for 5 minutes, add the mixed material into a parallel twin-screw extruder at a temperature of 170-200° C. to extrude and pelletize to obtain ASA pellets;

[0039] c. Take 720g of ASA particles prepared in step b and 210g of wood powder prepared in step a, then weigh 40g of compatibilizer EPDM-g-MAH, 9g of foaming agent AC, and 30g of lubricant zinc stearate, and put them together Put it into a high-speed mixer at 80°C and mix for 5 minutes, then add it to a conical twin-screw extruder to extrude...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com