Preparation method of tellurium diethyl dithiocarbamate, pre-dispersing masterbatch particles comprising tellurium diethyl dithiocarbamate and preparation method thereof

A technology of diethyldithiocarbamic acid and pre-dispersed masterbatch, applied in the direction of organic chemistry, etc., can solve the problems such as difficulty in uniform dispersion of powder, low TDEC yield, low product purity, etc., to improve dispersibility, increase Operating comfort and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] The invention provides a new method for preparing tellurium diethyldithiocarbamate (TDEC) powder, which uses metal tellurium as the initial raw material, and successively adds concentrated acid and alkali solution to fully react with the metal tellurium powder. TDEC is prepared by reacting the tellurium-containing solution thus obtained with sodium diethyldithiocarbamate. The obtained TDEC is subjected to grinding treatment to obtain TDEC powder within a specific particle size range, kneaded with masterbatch carrier rubber, processing aids, active agents, oil, and coupling agent, extruded and granulated to obtain TDEC-containing predispersed masterbatches with high TDEC content suitable for incorporation into rubber.

[0067] The preparation method of TDEC provided by the invention comprises the following steps:

[0068] 1. Preparation of tellurium powder

[0069] The bulk tellurium metal is comminuted to a tellurium powder having an average particle size of less than...

Embodiment 1

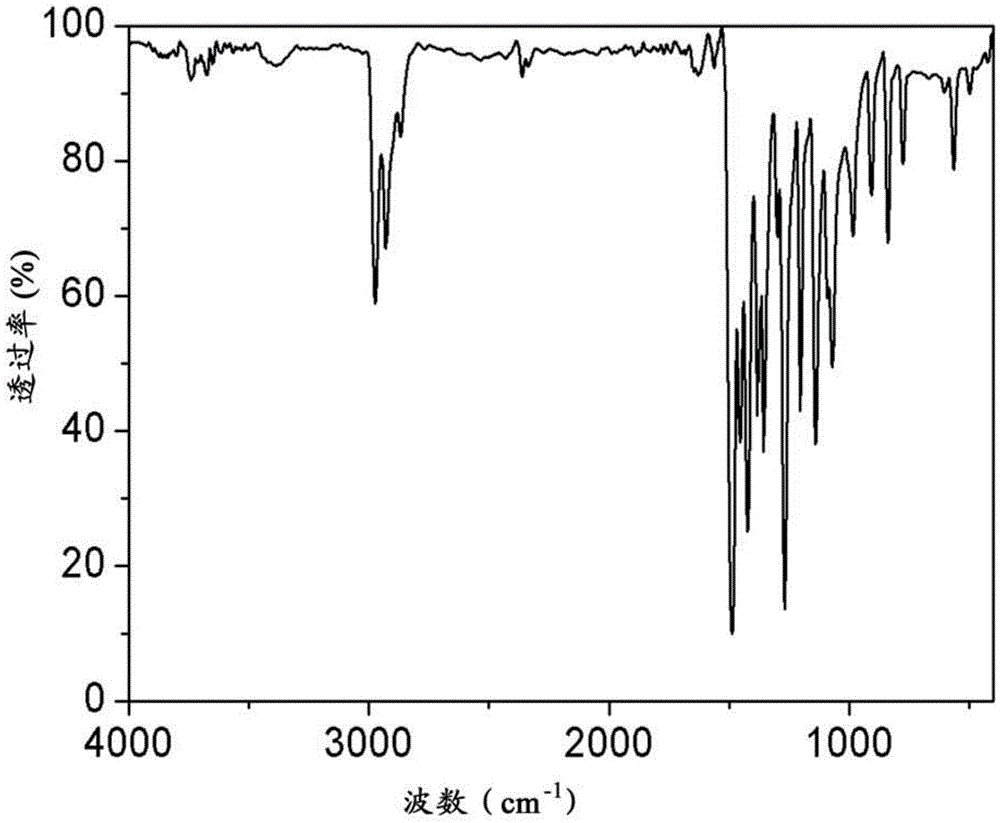

[0110] Put 24g of block metal tellurium into a laboratory universal pulverizer and pulverize it to control all particle sizes below 30 μm, put it in a 1L round bottom flask, add 95g of 98% concentrated nitric acid dropwise, after fully reacting, add 13% of 360g of sodium hydroxide solution, gradually warmed up to 45°C, slowly added dropwise for about 1.5 hours, kept stirring for 20 minutes, stopped the heat preservation and cooled to 30°C, the measured pH value was 12. Take 735g of 20% sodium diethyldithiocarbamate solution, stir at room temperature, add the above-mentioned tellurium-containing solution dropwise, after dropping for 15 minutes, add 380g of 40% hydrochloric acid dropwise at the same time, adjust the pH between 7-8, and dropwise complete After that, it was stirred for another 15 min, filtered and washed, and dried at 80°C to obtain 135 g of TDEC. The infrared spectrogram of this TDEC is measured, and the test conditions are: adopt the Nexus 6700 Fourier transform...

Embodiment 2

[0132] Put 5Kg block metal tellurium into an ultra-fine pulverizer to pulverize, control the total particle size to about 20 μm, place it in 1# reaction kettle, add 20Kg of 96% concentrated nitric acid dropwise, after fully reacting, add dropwise 18% 54Kg of NaOH solution, gradually warmed up to 60°C, slowly added dropwise for about 2 hours, kept stirring for 30 minutes, stopped keeping warm and cooled to room temperature, the measured pH value was between 11-12. Take 127Kg of 24% sodium diethyldithiocarbamate solution, put it in 2# reaction kettle, stir at room temperature, add the above-mentioned tellurium-containing solution dropwise, after 15 minutes, add 105Kg of 30% HCl dropwise at the same time, adjust the pH to 8 Between -8.5, after the dropwise addition, stir for another 30 minutes, filter and wash, and dry at 80°C to obtain 29.7Kg TDEC, wherein the tellurium content is 16.5%, and the initial melting point is 108°C.

[0133] Put the dried TDEC above into a jet mill to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com