Method for connecting materials difficult to connect through ultrafast lasers

A technology for connecting materials and ultra-fast lasers, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of difficult connection and low connection strength, and achieve the elimination of heat affected zone, flexible connection methods, and rich forms. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1, fs laser preparation of micro-protrusion arrays on W surface to enhance W / Cu connection strength

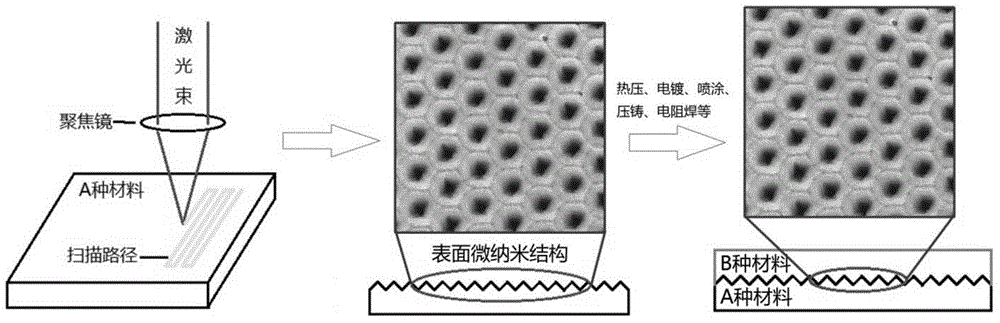

[0044] In this example, the fs laser is used to prepare micro-protrusion arrays on the W surface to enhance the connection strength of the W / Cu thermocompression connector. The flow chart is as follows figure 1 As shown, the specific steps are as follows:

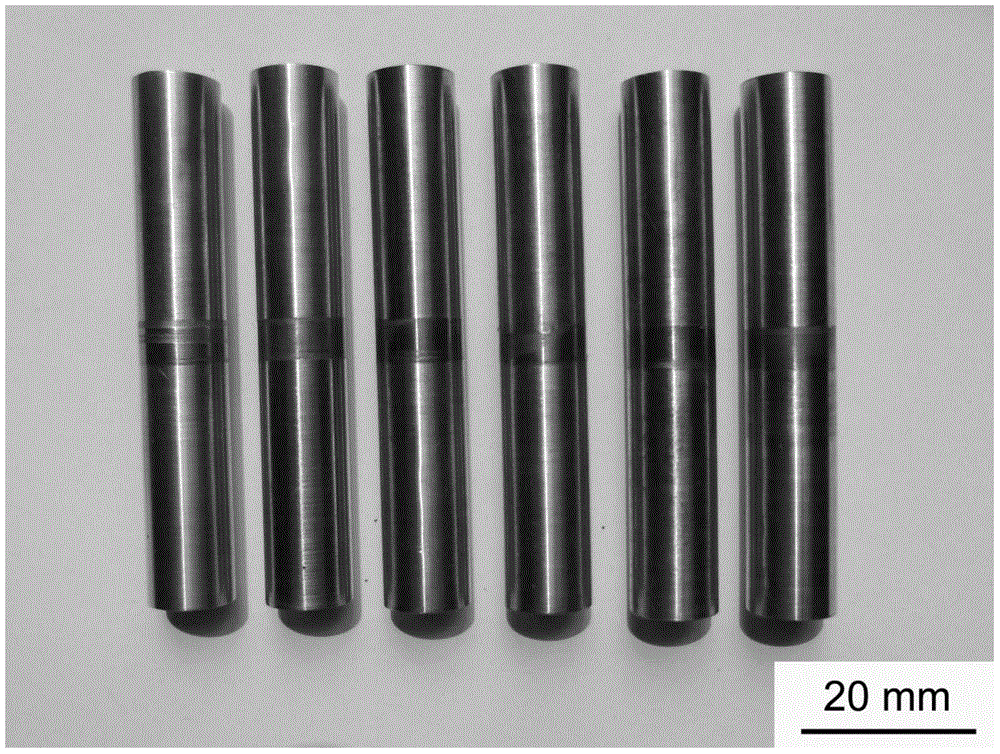

[0045] (1) First remove the oxide on the end face of the W rod by mechanical processing, and remove the oxide on the end face of the Cu rod by chemical corrosion (etching agent: dilute hydrochloric acid with a volume fraction of 5%), and then use a grinding and polishing machine to clean the W rod. Grinding and polishing with the end face of the Cu rod, then ultrasonically cleaning the W rod and the Cu rod with alcohol, and finally blowing them dry with a high-pressure nitrogen stream. Among them, the size of the W rod is Φ10mm×5mm, and the size of the Cu rod is Φ10mm×30mm.

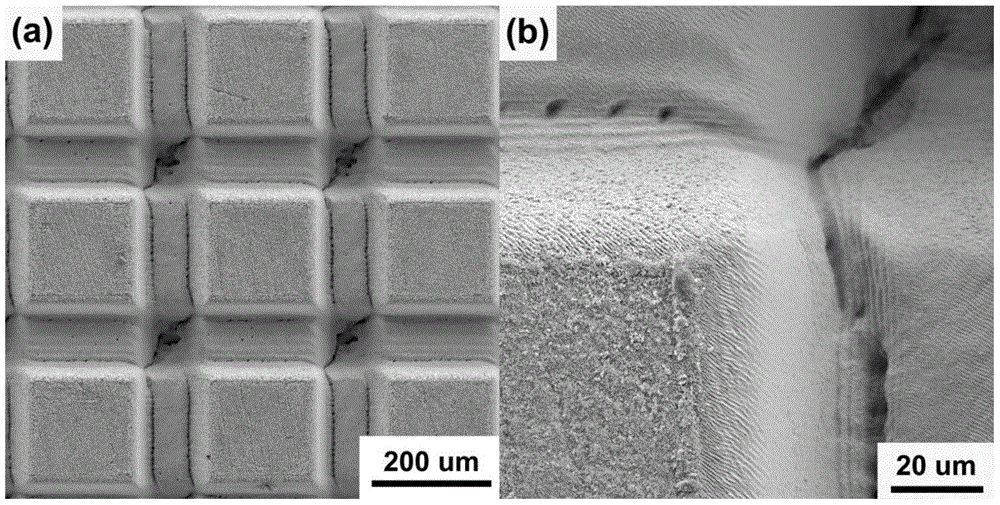

[0046] (2) Prepare the micro-n...

Embodiment 2

[0057] Example 2, fs laser preparation of micro-pit arrays on W surface to enhance W / Cu connection strength

[0058] In this example, the fs laser is used to prepare a micro-pit array on the W surface to enhance the connection strength of the W / Cu thermocompression connection. The schematic flow diagram is as follows figure 1 As shown, the specific steps are as follows:

[0059] (1) First remove the oxide on the end face of the W rod by mechanical processing, and remove the oxide on the end face of the Cu rod by chemical corrosion (etching agent: dilute hydrochloric acid with a volume fraction of 5%), and then use a grinding and polishing machine to clean the W rod. Grinding and polishing with the end face of the Cu rod, then ultrasonically cleaning the W rod and the Cu rod with alcohol, and finally blowing them dry with a high-pressure nitrogen stream. Among them, the size of the W rod is Φ10mm×5mm, and the size of the Cu rod is Φ10mm×30mm.

[0060] (2) Prepare the micro-n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pulse width | aaaaa | aaaaa |

| Average power | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com