Impurity filtering and absorbing flow divider for tundish

A tundish and shunt technology, which is applied in the field of suction shunt and tundish filtration, can solve the problems of unfavorable floating removal of inclusions, unsatisfactory slag removal effect, single length of conduit, etc. The effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with drawings and embodiments.

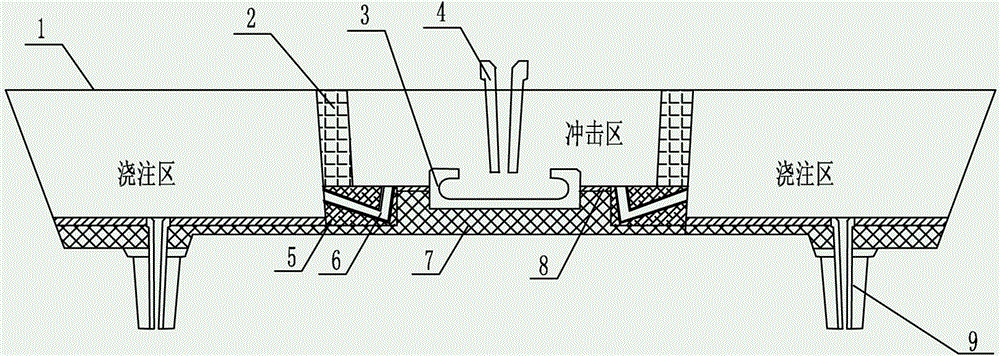

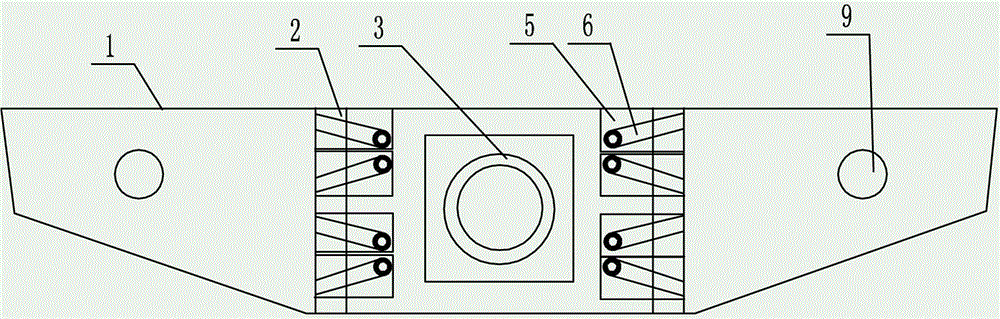

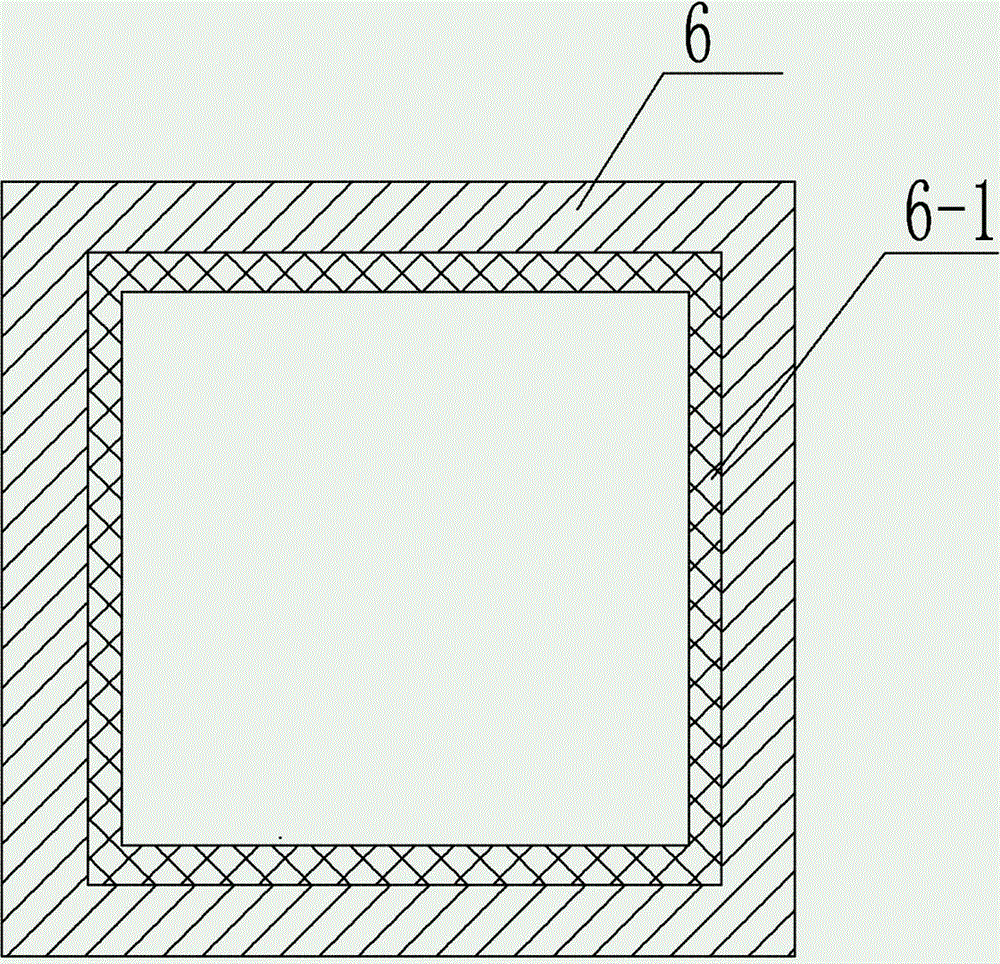

[0032] Such as Figure 1-5 Shown, a kind of filter for tundish of the present invention, absorbing miscellaneous diverter, comprises tundish body 1, has permanent layer 7 and working layer 8 on tundish body 1, is arranged on tundish nozzle 9 on the bottom surface of tundish body 1 , the slag retaining wall 2 in the tundish body is set, the slag retaining wall 2 divides the tundish body 1 into an impact area and a pouring area, the turbulence controller 3 is located below the long nozzle 4 of the tundish impact area, and the pouring area is set The shunt filter connected to the impact area is characterized in that the shunt filter is arranged under the slag retaining wall 2, and consists of a shunt filter body 5, and several through-holes embedded in the shunt filter body 5 And it is composed of a "V" or "U" shaped filter element 6, the inlet end of the "V" or "U" shape...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com