Liquid opening machine

An opener and liquid technology, applied in the field of leather processing equipment, can solve the problems of increased working resistance, inability to work continuously, and not smooth, and achieve the effects of reducing working resistance, improving working efficiency, and overcoming technical defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

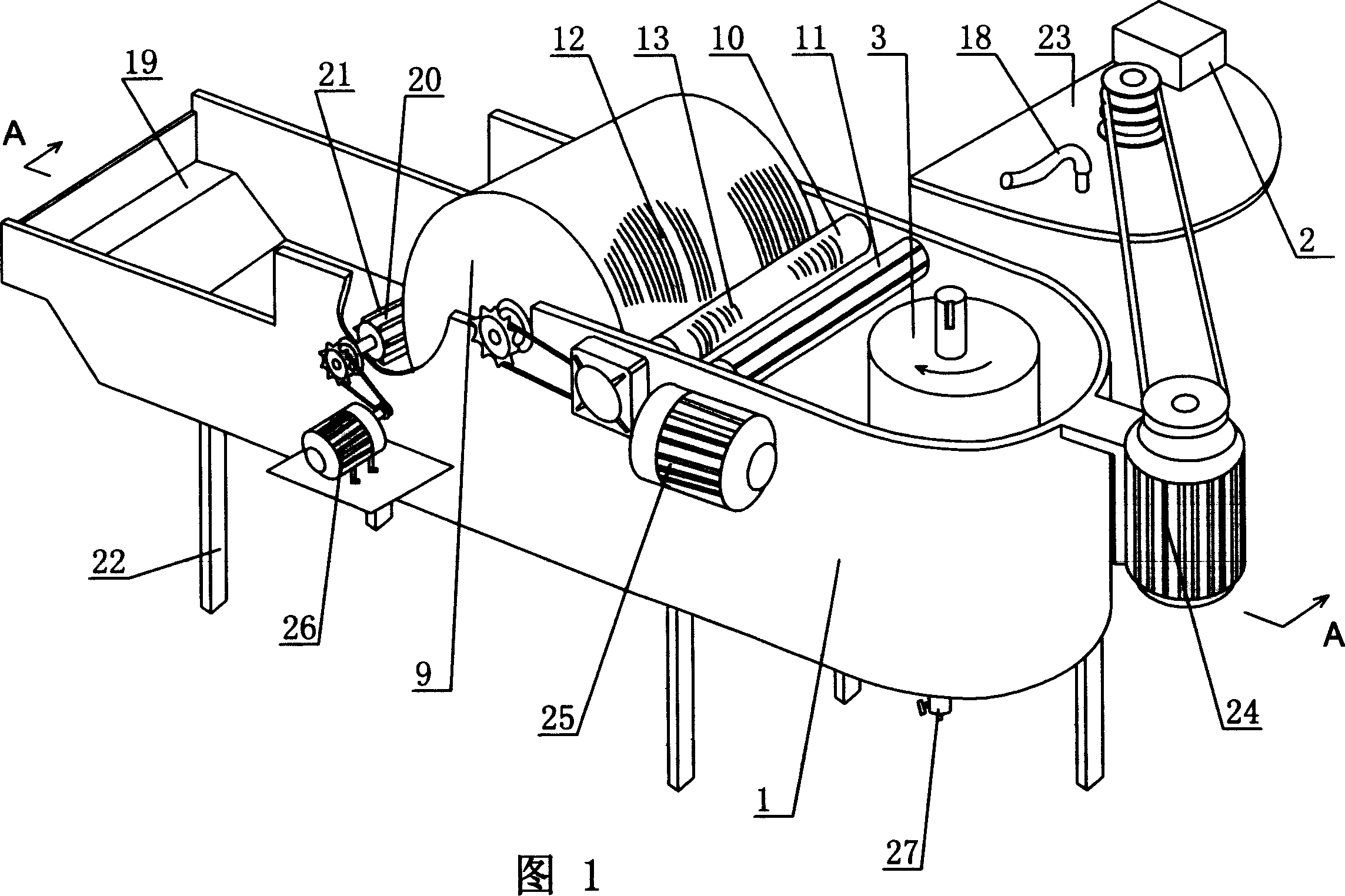

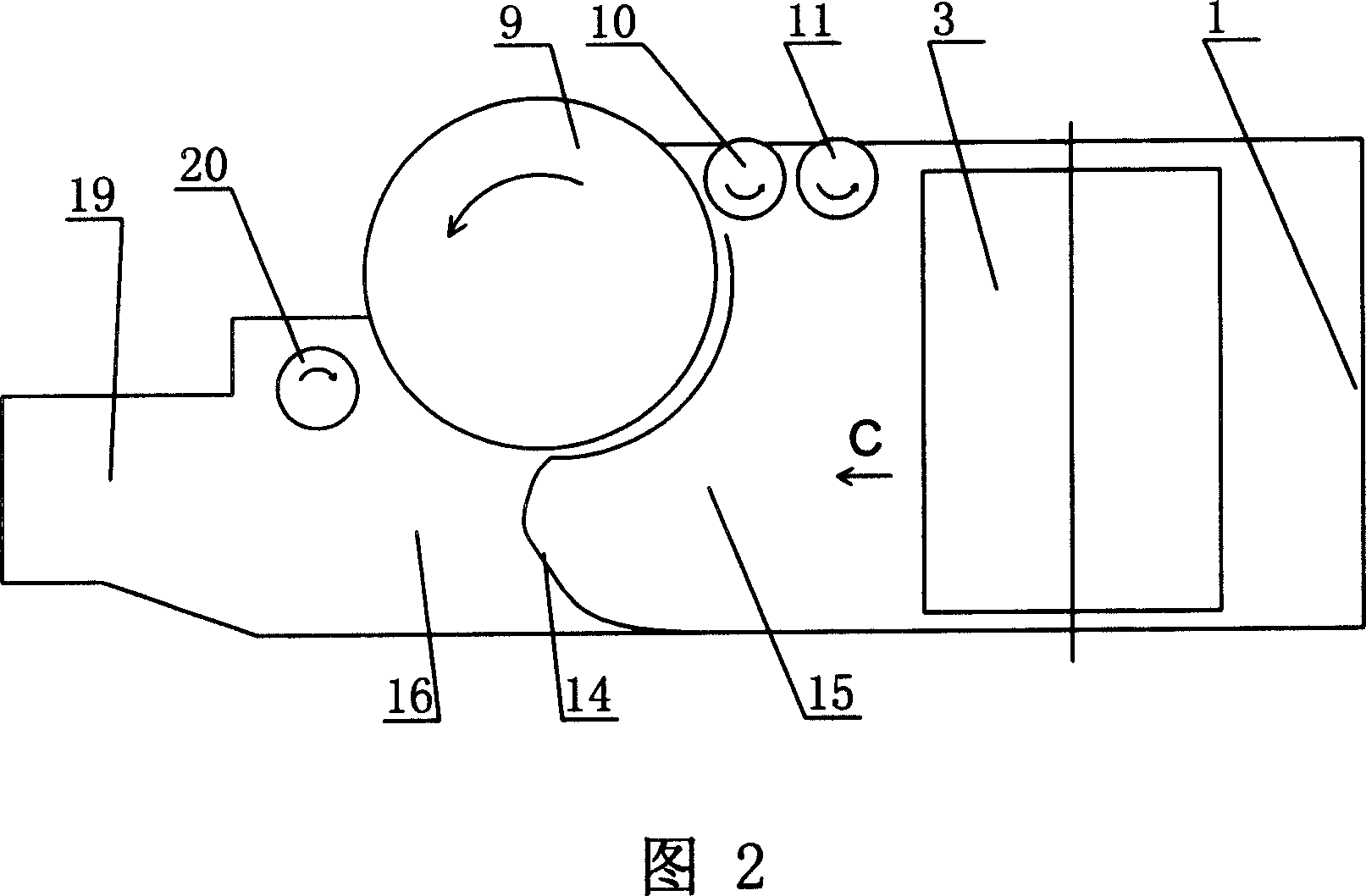

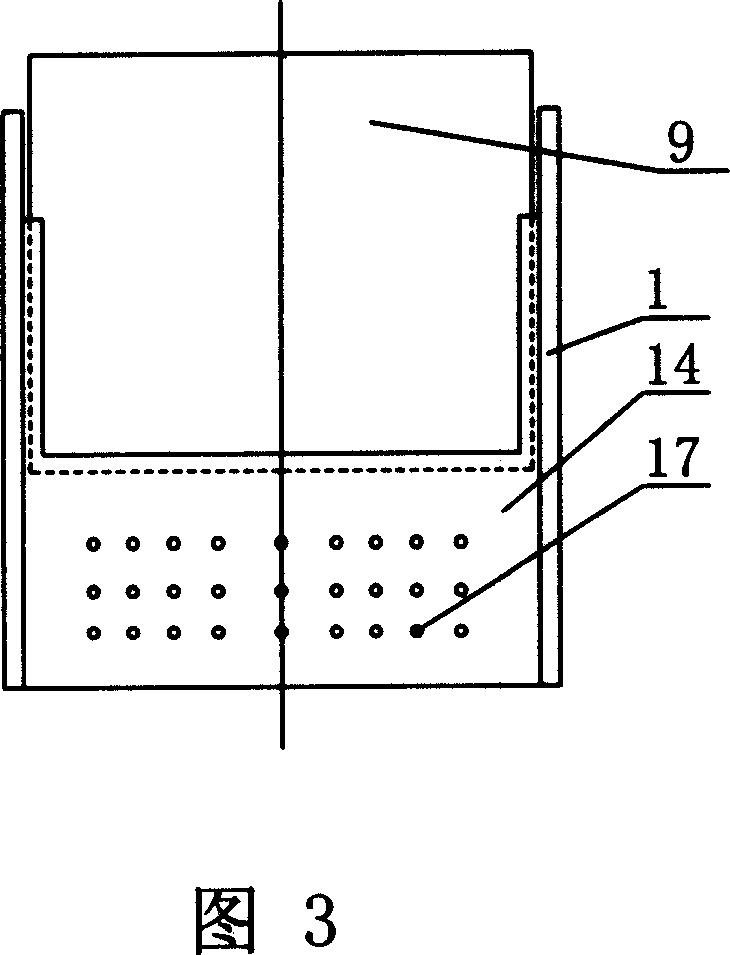

[0054] See Figures 1, 2, 3, 4, 9, 10, and 11. The liquid opener in this embodiment includes a housing 1, a plurality of legs 22 are provided at the lower part of the housing 1, and a discharge port is provided on one side of the housing 1. Port 19, the front end of the housing 1 is semicircular to form a D-shape, and a rotor 3 is arranged inside it. The rotor 3 and the D-shaped part of the housing 1 form an opening mechanism. The rotor 3 includes a rotor body 4 and a paddle 5 , the rotor main body 4 is a truncated conical shape, and the spiral plectrum 5 is arranged on the side of the rotor main body 4, and the spiral plectrum 5 is provided with gap contact pieces 7, and the distance between each contact piece 7 is 7 cm ; The position corresponding to the rotor 3 on the housing 1 is provided with a shell cover 23 , and the shell cover 23 is provided with a feed port 2 and a liquid intake port 18 . In the housing 1, a fiber leather separation mechanism is provided at the rear o...

Embodiment 2

[0059] See Fig. 5, the difference between this embodiment and the first embodiment is that the paddle 5 is arranged on the rotor 3 in the circumferential direction, the direction of the paddle 5 is parallel to the axis of the rotor main body 4, in each paddle 5, from top to bottom , the radial dimension of the plectrum 5 increases gradually. In this embodiment, only the structure of the plectrum 5 is different, and the rest of the structure and working principle are the same as those in the first embodiment, and will not be repeated here.

Embodiment 3

[0061] See Figures 6, 7, and 8. The difference between this embodiment and Embodiment 1 is that: the rotor 3 is provided with a boss 6, and the boss 6 is provided with gap-type contacts 7 or blunt nails 8, and the boss 6 The effect of 6 is to strengthen the effect of rotor 3 to the agitation of water, and contact piece 7 or blunt nail 8 are in order to improve the chance of skin block collision. The remaining structures and working principles of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com