A kind of preparation method of visible light absorbing layer based on Ag3PO4 thin film

A technology of absorbing layer and visible light, applied in the field of photoelectric material preparation and photocatalysis, can solve the problems of difficult recovery of base photocatalyst, difficult photoelectric energy conversion, etc., and achieve the effect of low cost, easy thickness control and good adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

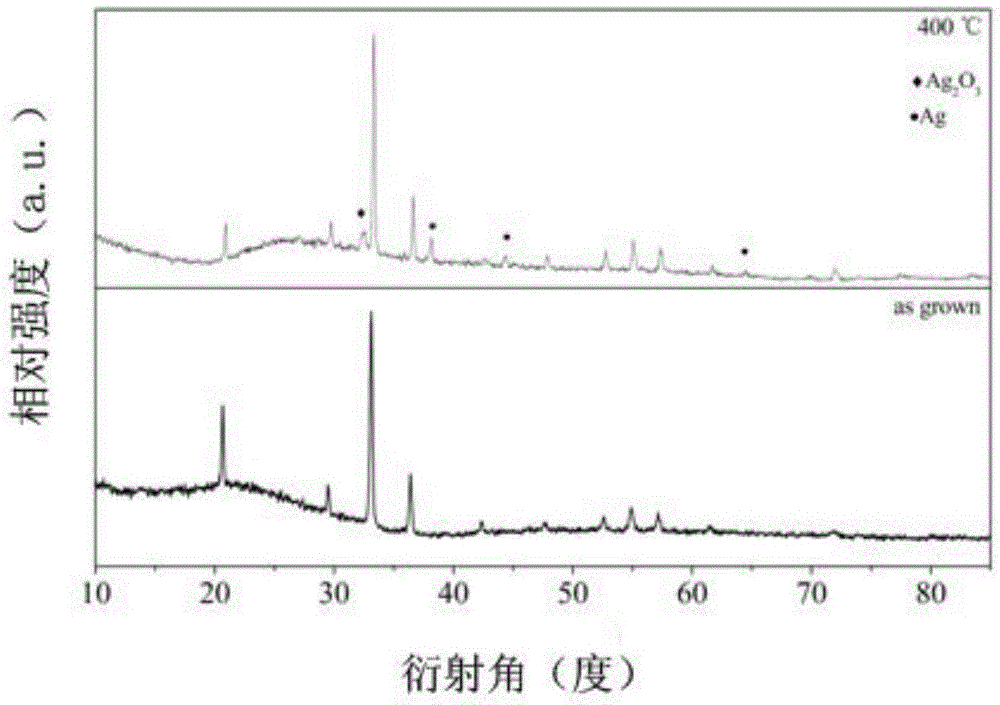

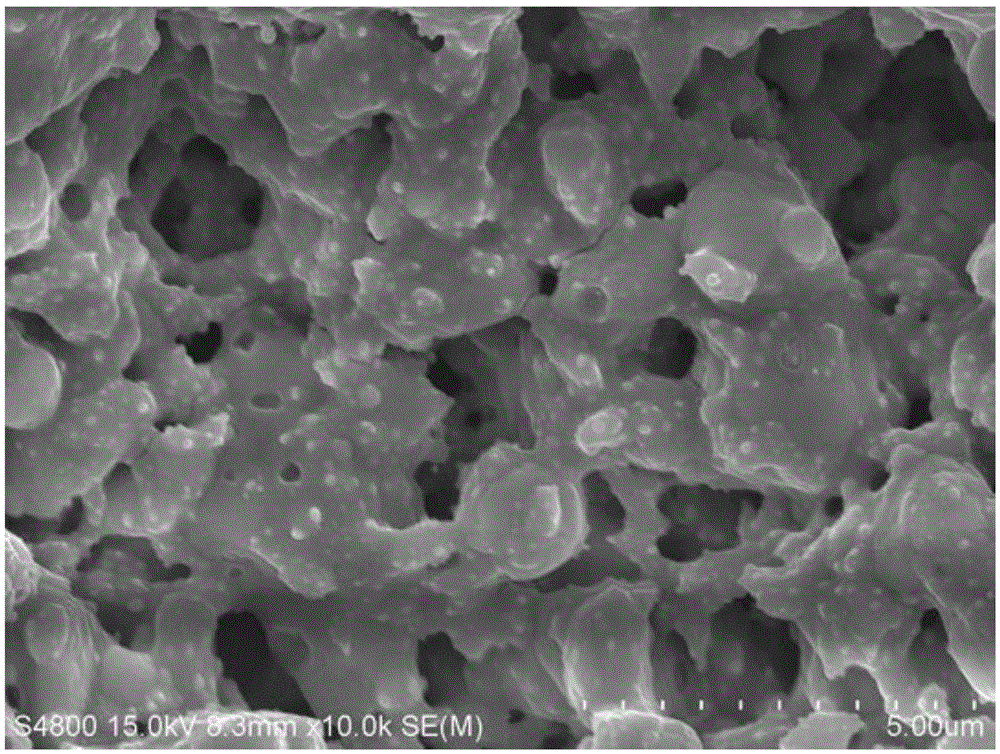

[0018] The preparation method of the visible light absorption layer is: the four-step process of "co-precipitation-spin coating-drying-sintering" is used. Steps: 1) Co-precipitation method is used to obtain Ag 3 PO 4 Nano powder, the size of the powder is in the range of 20~500nm; 2) Ag 3 PO 4 The powder is dissolved and dispersed in a transparent organic carrier to obtain a precursor sol, and then the obtained precursor sol is spin-coated on the substrate by a spin coating method to obtain a prefabricated Ag 3 PO 4 Thin film; 3) prefabricated Ag 3 PO 4 The film is dried in an oven at 20-80℃; 4), the dried Ag 3 PO 4 The prefabricated film is sintered in a muffle furnace to remove organic solvent residues.

[0019] The transparent organic carrier is composed of terpineol and ethyl cellulose, and their mass ratio is 10:1 to 5:1.

[0020] Ethyl cellulose and Ag in the precursor sol 3 PO 4 The mass ratio of the powder is 0.03:1 to 0.1:1.

[0021] The heat preservation stage of the sinteri...

Embodiment 1

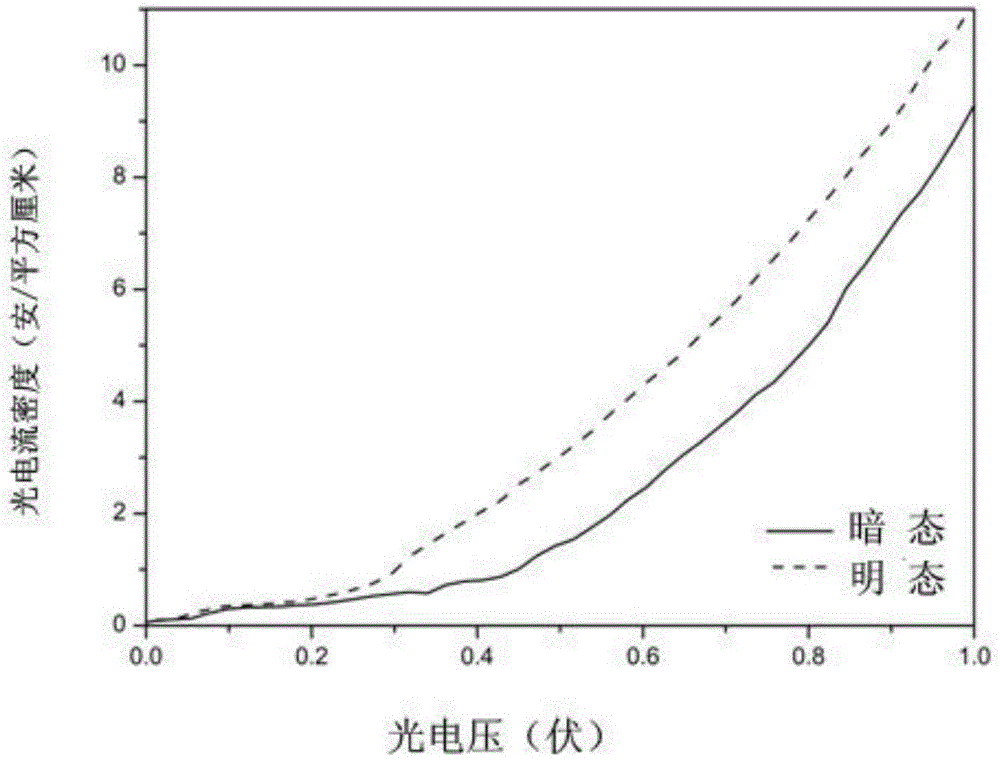

[0022] Example 1: Using fluorine tin oxide (FTO) conductive glass as a substrate, 0.4g of ethyl cellulose was added to 5mL of terpineol and stirred at room temperature for 24 hours to obtain a transparent viscous liquid, which was prepared by taking 0.5g of co-precipitation method Ag 3 PO 4 Grind for 30 min, add to 375 μL of the above transparent viscous liquid, and stir for 2 h to obtain a gel. Place the FTO conductive glass on the homogenizer, drop the gel in the center, spin-coating at a low speed of 1000r / min for 10s, and then spin-coating at a high speed of 3000r / min for 60s to obtain a film. The spin-coated film was dried in an oven at 60°C for 12 hours, and then placed in a muffle furnace for sintering. Raise the temperature from room temperature to 125°C at a rate of 1°C / min, hold for 30 minutes, then heat up to 400°C at a rate of 10°C / min, hold for 90 minutes, and cool to room temperature naturally to obtain a stronger film. Will be prepared Ag 3 PO 4 The base film is...

Embodiment 2

[0023] Example 2: Using indium tin oxide (ITO) conductive glass as a substrate, 0.4 g of ethyl cellulose was added to 4.5 mL of terpineol and stirred at 60°C for 12 hours to obtain a transparent viscous liquid. Take 0.4 g of Ag 3 PO 4 Grind for 30min, add to 225μL of the above transparent viscous liquid, stir for 2h to obtain a gel. The film was obtained by knife coating, dried in an oven at 50°C for 12 hours, and then placed in a muffle furnace for sintering. Raise the temperature from room temperature to 125°C at a rate of 1°C / min, hold for 30 minutes, then heat up to 375°C at a rate of 10°C / min, hold for 90 minutes, and cool to room temperature naturally to obtain a stronger film. Will be prepared Ag 3 PO 4 The base film photoanode is used in the electrochemical workstation, the Pt electrode is used as the counter electrode, the calomel electrode is used as the reference electrode, and the 0.1M potassium nitrate aqueous solution is used as the electrolyte.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com