Production method of ultrahigh molecular weight polyethylene fiber

An ultra-high molecular weight, polyethylene fiber technology, applied in the direction of single-component polyolefin rayon, fiber processing, spinning solution preparation, etc. The macromolecular chain is prone to breakage and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

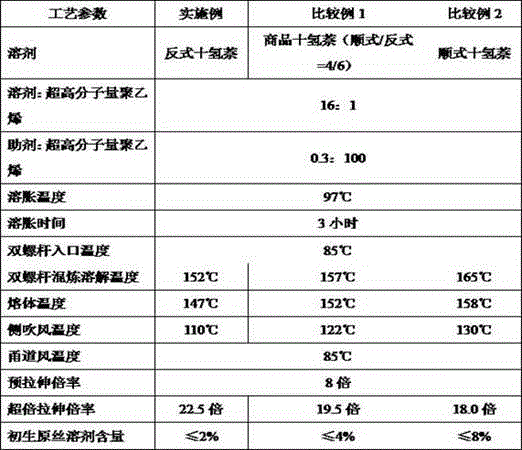

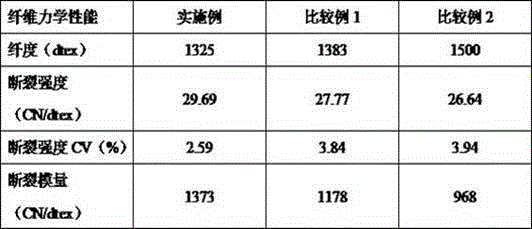

[0024] In order to further understand the present invention, the preferred embodiments of the present invention will be described below in conjunction with the examples and accompanying drawings, and the advantages of the present invention will be highlighted by comparison.

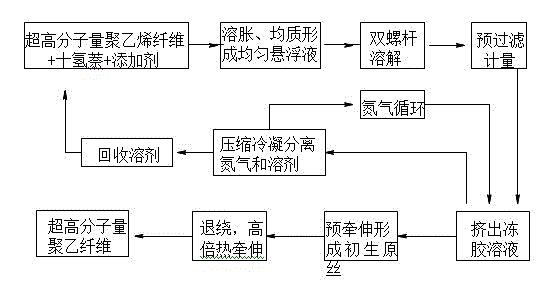

[0025] Embodiment: the technical process of this embodiment is attached figure 1 , the main steps are:

[0026] 1. The ultra-high molecular weight polyethylene is swollen and dissolved by a solvent to make a spinning jelly solution, and then extruded through a spinneret to obtain a thin stream of the solution. The solvent used is trans-decalin, and the trans-decalin solvent and ultra-high molecular weight polyethylene are mixed according to the ratio of 20:1~5:1, and swelled at 90°C~100°C for 2~4 hours, and then Cool the swollen ultra-high molecular weight polyethylene suspension to room temperature and feed it into the twin-screw extruder. The inlet temperature of the twin-screw is 85°C~95°C, the middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com