Method for processing reverse-osmosis concentrated water through catalytic ozone oxidation

A technology of reverse osmosis concentrated water and ozone oxidation, which is applied in the fields of oxidized water/sewage treatment, chemical instruments and methods, special compound water treatment, etc., to achieve the effect of rich pores, many surface active groups and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

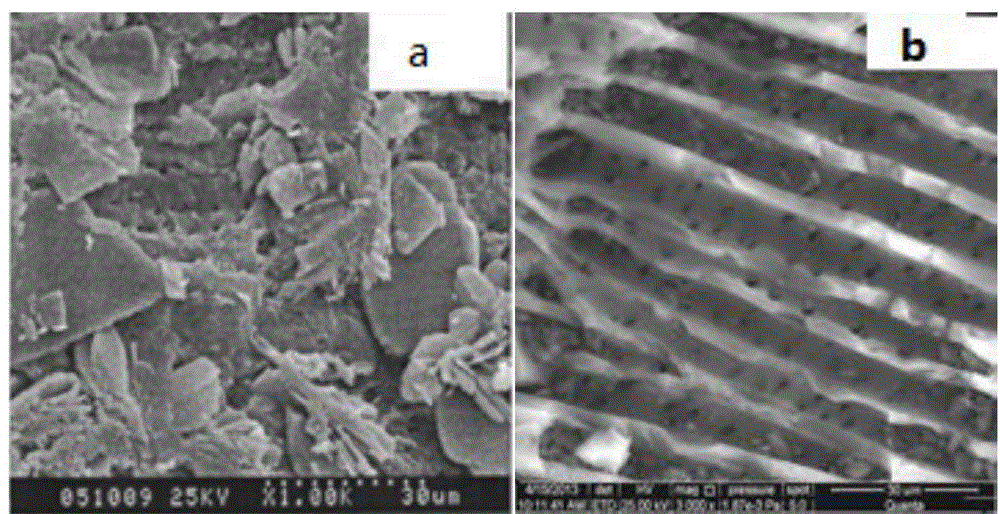

[0021] Immerse peanut shell powder and 60% phosphoric acid solution at a solid-to-liquid g / g ratio of 1:2 for 14 hours, move the material liquid to a crucible and activate it in a muffle furnace at 550°C for 2 hours, cool, wash with 1% hydrochloric acid solution, and then use Wash it with ionized water until pH = 7, put it in an oven and dry it at 105°C to constant weight, pass through a 100-mesh sieve after grinding or ball milling, and obtain activated carbon from peanut shells. The scanning electron microscope results are shown in figure 1 (a is commercial activated carbon; b is peanut shell activated carbon). The surface physical and chemical properties of commercial activated carbon and peanut shell activated carbon were obtained by nitrogen low-temperature adsorption-desorption isotherm, as shown in Table 1. It can be seen that the peanut shell activated carbon has abundant pores and a large specific surface area.

[0022] Table 1

[0023]

Embodiment 2

[0025] The peanut shell activated carbon was impregnated with 5% Cu 2+ solution (solid-to-liquid ratio: 1:10), oscillated on a shaking table for 24 hours, filtered, dried in an oven at 105°C, and then baked in a muffle furnace at 400°C for 4 hours, crushed and sieved (100 mesh) after cooling, and prepared The catalyst was obtained, and the surface physical and chemical properties of the peanut shell activated carbon-supported metal ion catalyst were obtained by nitrogen low-temperature adsorption-desorption isotherm, as shown in Table 2. It can be seen that the specific surface area of the prepared catalyst is increased.

[0026] Table 2

[0027]

Embodiment 3

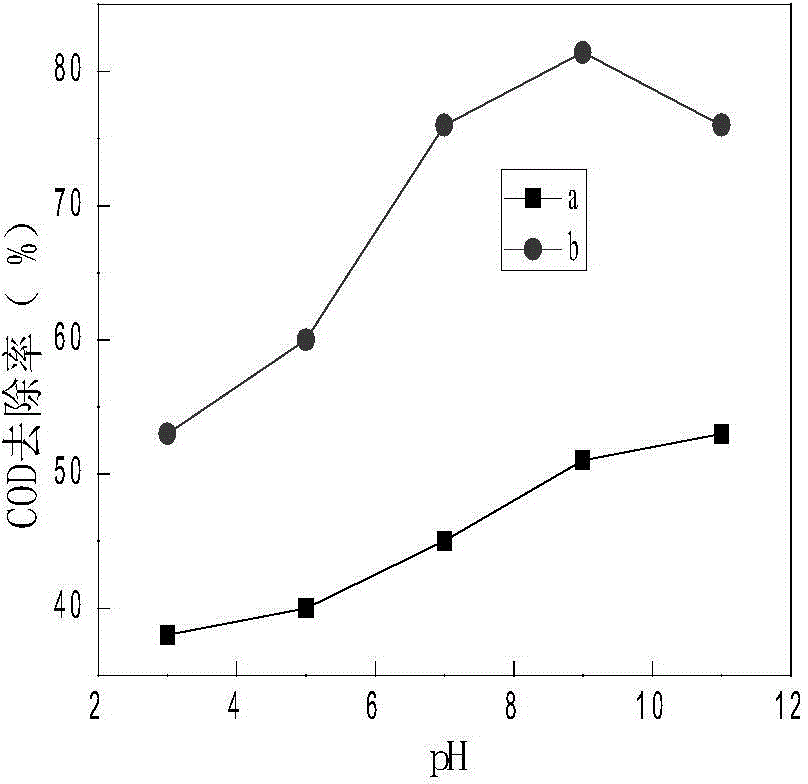

[0029] Adjust the pH to 3, 5, 7, 9, and 11 in 2L of reverse osmosis concentrated water, add 8g of peanut shell activated carbon supported copper ion catalyst, pass ozone at the reaction temperature of 20°C, control the dosage of ozone to 30mg / L, and react After 60min, measure and calculate the removal rate of COD. The result is as figure 2 As shown, a is ozone oxidation alone (no catalyst), and b is ozone oxidation catalyzed by peanut shell activated carbon loaded with copper ions. It indicated that the addition of catalyst significantly promoted the degradation of pollutants in sewage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com