Degradable plastic film and preparation method thereof

A technology for plastic films and raw materials, applied in the field of degradable films, can solve the problems of low recycling efficiency and cannot be completely removed, and achieve the effects of improving strength, improving biodegradability, and reducing difficulty and time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

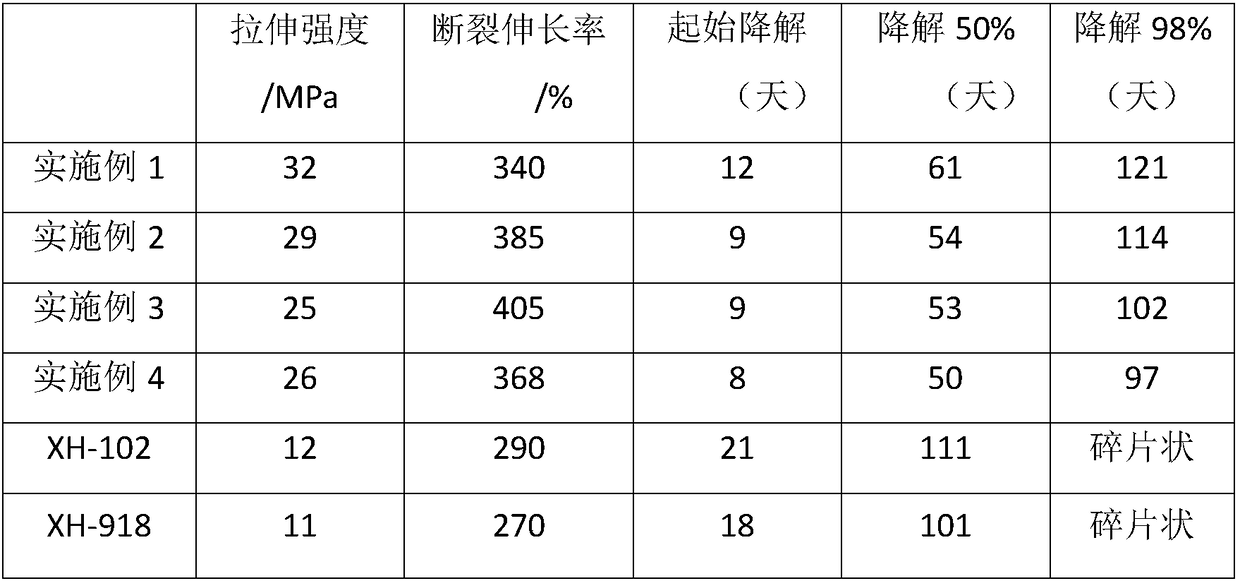

Examples

Embodiment

[0023] A kind of degradable plastic film is provided in the present embodiment, the raw material of this degradable plastic film is constituted as follows according to mass fraction: thermoplastic polyurethane resin 47-62 parts, modified polylactic acid resin 10-25 parts, polyvinyl alcohol 7-15 parts 7-10 parts of plasticizer, 5-8 parts of inorganic filler, 5-8 parts of maltodextrin, 2-5 parts of chitosan oligosaccharide, and 2-5 parts of lignocellulose.

[0024] Among them: thermoplastic polyurethane resin is polyethylene adipate glycol ester TPU, polyethylene glycol propylene glycol adipate TPU, polyethylene adipate butylene glycol ester TPU, polyadipate Ethylene glycol diethylene glycol ester type TPU, polyethylene adipate neopentyl glycol ester type TPU, polyethylene succinate neopentyl glycol ester type TPU, polyethylene succinate propylene glycol ester type TPU, polyethylene succinate butylene glycol ester type TPU, polyethylene succinate diethylene glycol ester type TPU...

specific Embodiment 1

[0032] The present embodiment provides a kind of degradable plastic film, becomes by weight parts:

[0033] 62 parts of thermoplastic polyurethane resins, selected in the present embodiment is polyethylene adipate glycol ester type TPU;

[0034] 10 parts of modified polylactic acid resin;

[0035] 7 parts of polyvinyl alcohol, polyvinyl alcohol in the present embodiment is brand PVA124, degree of polymerization is 24,000-25,000, molecular weight is 105000, degree of alcoholysis is 99%, viscosity (4%, 20 ℃) is 55-67mPa.s ;

[0036] 7 parts of plasticizer, in the present embodiment plasticizer is citric acid ester (WT-1);

[0037] 5 parts of inorganic fillers, in the present embodiment, the inorganic fillers are anatase titanium dioxide;

[0038] 5 parts of maltodextrin. In this example, maltodextrin is made from cornstarch, which is hydrolyzed and converted through enzymatic process control;

[0039] 2 parts of chitosan oligosaccharide, chitosan oligosaccharide is added a...

specific Embodiment 2

[0043] A kind of degradable plastic film, becomes by weight parts:

[0044] 47 parts of thermoplastic polyurethane resins, selected in the present embodiment is polyethylene adipate glycol neopentyl glycol ester type TPU;

[0045] 25 parts of modified polylactic acid resins;

[0046] 7 parts of polyvinyl alcohol, polyvinyl alcohol in the present embodiment is brand PVA124, degree of polymerization is 24,000-25,000, molecular weight is 105000, degree of alcoholysis is 99%, viscosity (4%, 20 ℃) is 55-67mPa.s ;

[0047] 7 parts of plasticizer, in the present embodiment, plasticizer is epoxy soybean oil;

[0048] 5 parts of inorganic fillers, in the present embodiment, inorganic fillers are nano active calcium carbonate;

[0049] 5 parts of maltodextrin. In this example, maltodextrin is made from wheat starch, which is hydrolyzed and converted through enzymatic process control;

[0050] 2 parts of chitosan oligosaccharide, in this embodiment, chitosan oligosaccharide is spec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com