Method of performing chloridizing roasting to synchronously reduce and recover gold and iron from gold concentrate cyanide tailings

A technology of cyanidation tailings and chlorination roasting is applied in the field of comprehensive utilization of resources, which can solve the problems of high cost, inability to handle, large heat consumption requirement, etc., and achieve the effects of improving grade and reducing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The main components of the cyanide tailings of a gold concentrate are: gold grade 3.48g / t, copper grade 0.04%, iron grade 22.36%, phosphorus grade 0.74%, sulfur grade 1.17%, silica content 36%. The main metal minerals are hematite, magnetite, pyrite, etc., and the main gangue minerals are quartz, feldspar, silicate, etc.

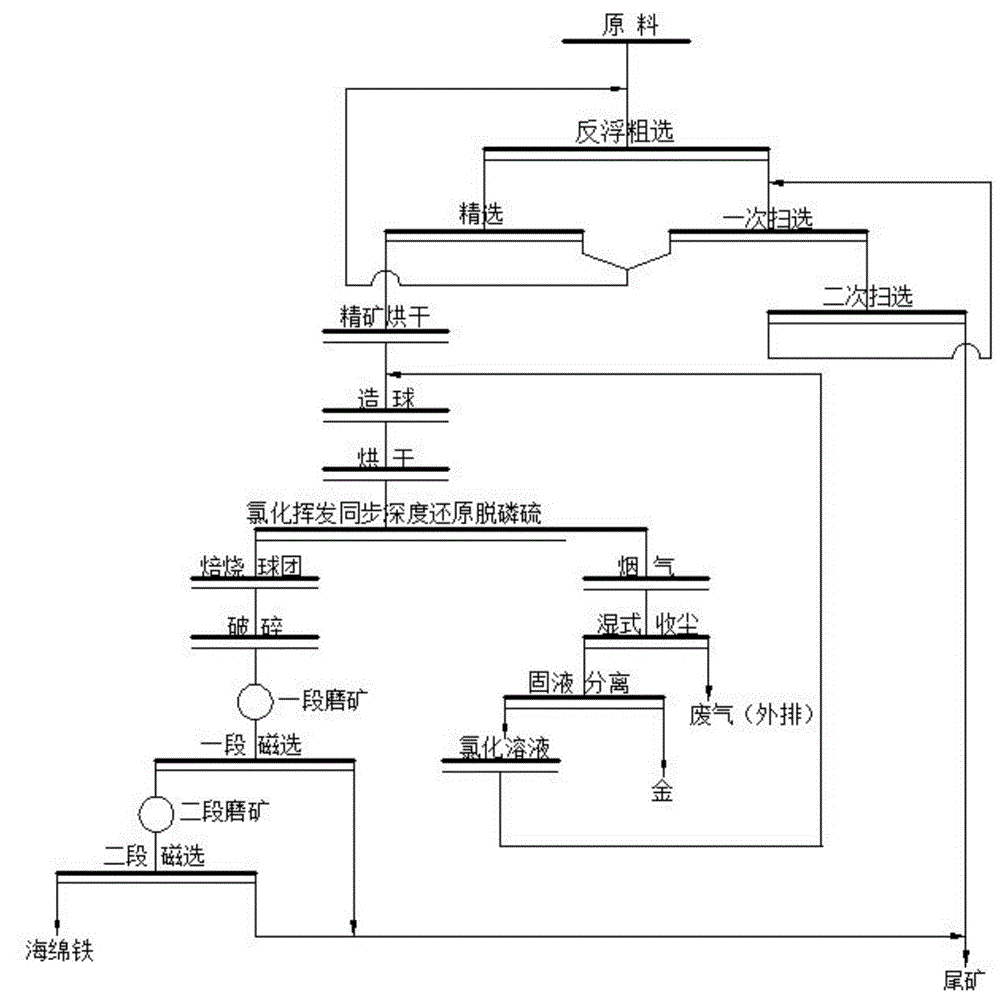

[0037] according to figure 1 The shown technological process carries out recovery gold, iron, and concrete steps are as follows:

[0038] (1) reverse flotation pre-enrichment

[0039] (a) Add water to the gold concentrate cyanide tailings to adjust the slurry to a mass concentration of 20%, and control the slurry temperature to 30°C.

[0040] (b) Add 600g / t of sodium hydroxide and stir for 2min; add 900g / t of modified starch and stir for 5min; add 400g / t of modified lime and stir for 4min; add 800g / t of sodium oleate and stir for 4min; Flotation roughing to obtain reverse flotation roughing concentrate and reverse flotation roughing tailings.

[0...

Embodiment 2

[0059] The chemical analysis results of cyanidation tailings of a gold concentrate are as follows: gold grade 4.26g / t, iron grade 24.10%, phosphorus grade 0.91%, sulfur grade 1.32%, silica content 32.85%. The results of process mineralogy show that the main metal minerals in tailings are hematite, magnetite and pyrite, etc., and the main gangue minerals are quartz, feldspar, silicate and so on.

[0060] according to figure 1 The shown technological process carries out recovery gold, iron, and concrete steps are as follows:

[0061] (1) reverse flotation pre-enrichment

[0062] (a) Add water to the gold concentrate cyanidation tailings to adjust the slurry to a mass concentration of 30%, and control the slurry temperature to 35°C.

[0063] (b) Add 800g / t of sodium hydroxide and stir for 3min; add 1200g / t of modified starch and stir for 7min; add 600g / t of modified lime and stir for 6min; add 1000g / t of sodium oleate and stir for 7min; Flotation roughing to obtain reverse flo...

Embodiment 3

[0082] A gold concentrate cyanide tailings was chemically analyzed, the results are as follows: gold grade 4.02g / t, iron grade 21.84%, lead grade 0.01%, zinc grade 0.05%, phosphorus grade 0.62%, sulfur grade 1.05%, The silicon content is 40.18%. The results of process mineralogy show that the main metal minerals in tailings are hematite, magnetite and pyrite, etc., and the main gangue minerals are quartz, silicate and feldspar.

[0083] according to figure 1 The shown technological process carries out recovery gold, iron, and concrete steps are as follows:

[0084] (1) reverse flotation pre-enrichment

[0085] (a) Add water to the gold concentrate cyanidation tailings to adjust the slurry to a mass concentration of 25%, and control the slurry temperature to 32°C.

[0086] (b) Add 700g / t of sodium hydroxide and stir for 3min; add 1000g / t of modified starch and stir for 6min; add 500g / t of modified lime and stir for 5min; add 950g / t of sodium oleate and stir for 5min; Flotat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com