Nano composite fiber-reinforced gel polymer electrolyte and preparation method thereof

A technology of nanocomposite fibers and gel polymers, applied in the manufacture of electrolyte batteries, organic electrolytes, non-aqueous electrolytes, etc., can solve the problems of battery cycle performance deterioration, achieve improved electrochemical performance and mechanical performance, low energy consumption, The effect of simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Preparation of electrospinning dope. Dissolve 10 g of PVDF powder in a mixed system of 20 g of N,N′-dimethylacetamide and 50 g of acetone, stir at 50°C to form a transparent solution, add 0.5 g of silica nanoparticles (average particle size 30 nm), 1 g of PMMA The monomer was ultrasonically stirred for 1 hour to obtain the electrospinning stock solution.

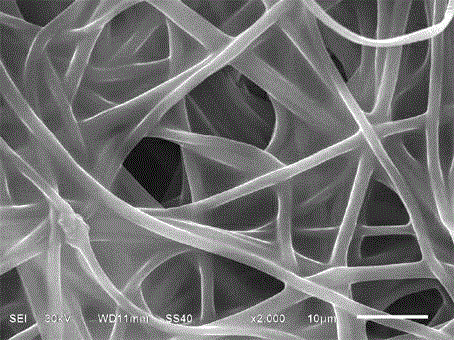

[0033] (2) Nanocomposite SiO 2 / PVDF-b-PMMA blend polymer fiber membrane preparation. Inject the spinning stock solution into the high-voltage electrospinning equipment, use aluminum foil as the receiving screen, and carry out electrospinning under the conditions of a voltage of 25kV, a spinning speed of 0.6 ml / min, and a distance from the spinneret to the receiving screen of 20cm. , the fiber filaments are superimposed into a film, and the thickness is controlled to be 60 μm; the fiber film is peeled off from the aluminum foil, placed in a vacuum oven at 80 ° C, and dried for 24 hours to obtain a nanocomposite ...

Embodiment 2

[0037] SiO in embodiment 1 2 Nanoparticles (average particle size 15 nm) replaced by Al 2 o 3 Nanoparticles (average particle size 30 nm), other conditions unchanged, prepared (Al 2 o 3 / PVDF-PMMA)-g-PMMA / Al 2 o 3 Nanocomposite Polymer Electrolytes. With 1.08×10 -3 Room temperature ionic conductivity in S / cm.

Embodiment 3

[0039] SiO in embodiment 1 2 Nanoparticles (average particle size 15 nm) replaced by TiO 2 Nanoparticles (average particle size 10 nm), other conditions unchanged, prepared (TiO 2 / PVDF-PMMA)-g-PMMA / TiO 2 Nanocomposite Polymer Electrolytes. With 1.57×10 -3 Room temperature ionic conductivity in S / cm.

[0040] The test and calculation formula description of the polymer electrolyte ionic conductivity: the polymer electrolyte membrane is sandwiched between two symmetrical stainless steel electrodes, sealed in a button cell, and the AC impedance test is carried out on the EG&G 273 electrochemical workstation, and the obtained Bulk resistance of polymer electrolyte R b into the formula k= d / ( S ? R b ), calculate the ionic conductivity k of the polymer electrolyte, where d is the thickness of the polymer electrolyte membrane, and S is the apparent area of the stainless steel electrode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com