Preparation process and application method of high heat conduction oil

A preparation process and technology of heat transfer oil, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of shortening the service life of heat transfer oil, increasing the viscosity of heat transfer oil, increasing the acid value of heat transfer oil, etc., to prolong the service life, The effect of low viscosity at low temperature and low toxicity of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

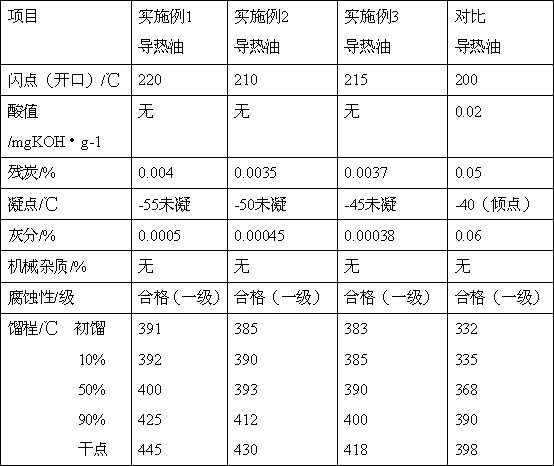

Examples

Embodiment 1

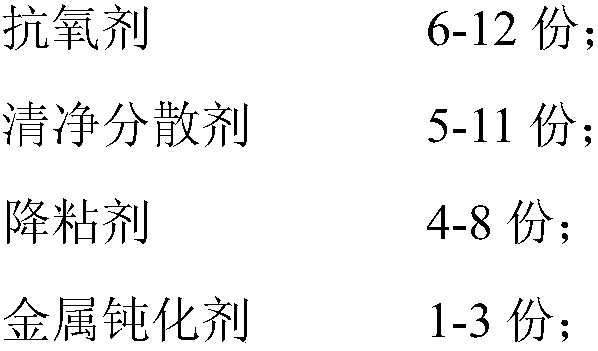

[0043] Embodiment 1: The present invention provides a preparation process and usage method of a high heat conduction oil, the preparation process of the high heat conduction oil is composed of the following parts, all of which are parts by weight:

[0044] 50 parts of Ⅱ type mineral oil;

[0045] 40 parts of alkylbenzene;

[0046] 10 parts of hydrogenated terphenyls;

[0047] Benzyltoluene 15 parts.

[0048] 1 part of 2,6-di-tert-butyl-α-dimethylamino-p-cresol;

[0049] 3 parts of N-n-butyl p-aminophenol;

[0050] 2 parts of 2,4,6-tri-tert-butylphenol;

[0051] 1 part calcium alkyl salicylate;

[0052] 1 part of polyisobutylene succinimide;

[0053] 2 parts of low alkali value barium petroleum sulfonate;

[0054] 1 part polyetheramine;

[0055] 2 parts of acetic acid-vinyl acetate copolymer;

[0056] Vinyl acetate-fumarate 1 part;

[0057] 1 part of alkenyl succinic acid.

[0058] The preparation process of the high heat conduction oil of the present invention is pr...

Embodiment 2

[0063] Embodiment 2: The present invention provides a preparation process and usage method of a high heat conduction oil, the preparation process of the high heat conduction oil is composed of the following parts, and the parts are parts by weight:

[0064] 55 parts of Ⅱ type mineral oil;

[0065] 45 parts of alkylbenzene;

[0066] 15 parts of hydrogenated terphenyls;

[0067] 20 parts of benzyltoluene;

[0068] 2 parts of 2,6-di-tert-butyl-α-dimethylamino-p-cresol;

[0069] 4 parts of N-n-butyl p-aminophenol;

[0070] 3 parts of 2,4,6-tri-tert-butylphenol;

[0071] 2 parts calcium alkyl salicylate;

[0072] 2 parts of polyisobutylene succinimide;

[0073] 3 parts of low alkali value barium petroleum sulfonate;

[0074] 2 parts polyetheramine;

[0075] 3 parts of acetic acid-vinyl acetate copolymer;

[0076] Vinyl acetate-fumarate 2 parts;

[0077] Alkenyl succinic acid 2 parts.

[0078] The preparation process of the high heat conduction oil of the present inventio...

Embodiment 3

[0083] Embodiment 3: The present invention provides a preparation process and usage method of a high heat conduction oil. The preparation process of the high heat conduction oil consists of the following parts, all of which are parts by weight:

[0084] 60 parts of Ⅱ type mineral oil;

[0085] 50 parts of alkylbenzene;

[0086] 20 parts of hydrogenated terphenyls;

[0087] 25 parts of benzyltoluene;

[0088] 3 parts of 2,6-di-tert-butyl-α-dimethylamino-p-cresol;

[0089] 5 parts of N-n-butyl p-aminophenol;

[0090] 4 parts of 2,4,6-tri-tert-butylphenol;

[0091] 3 parts calcium alkyl salicylate;

[0092] 2 parts of polyisobutylene succinimide;

[0093] 4 parts of low alkali value barium petroleum sulfonate;

[0094] 2 parts polyetheramine;

[0095] 3 parts of acetic acid-vinyl acetate copolymer;

[0096] Vinyl acetate-fumarate 3 parts;

[0097] Alkenyl succinic acid 2 parts.

[0098] The preparation process of the high heat conduction oil of the present invention is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com