Highly corrosion-resistant shop primer

A shop primer and corrosion-resistant technology, applied in the field of coatings, can solve problems such as damage to steel structural parts with poor anti-corrosion performance, affect the anti-corrosion performance of coatings, and poor thermal stability, and achieve strong weather resistance, excellent adhesion strength, and low cost of use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

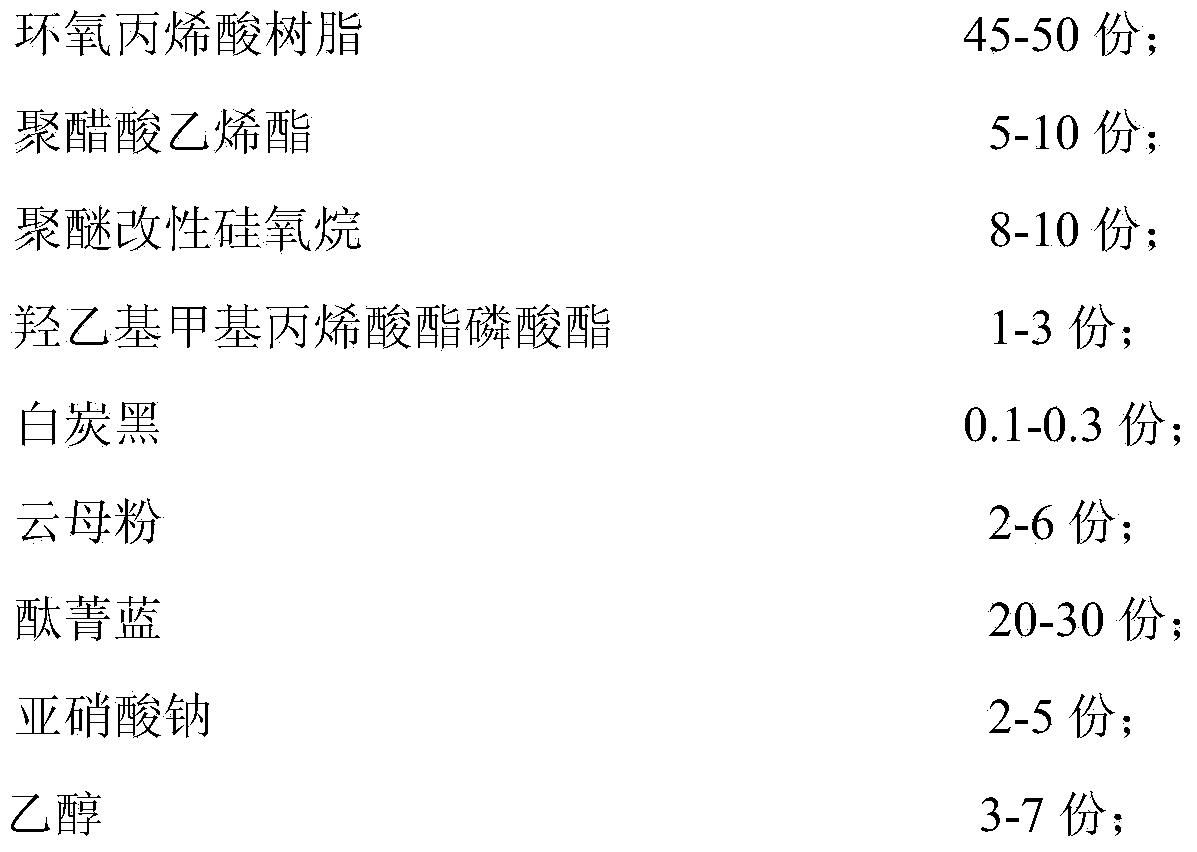

[0017] A high corrosion-resistant shop primer, comprising the following components in parts by weight:

[0018]

[0019]

[0020] The dispersant is a polymer polyurethane polymer with a molecular weight of 10,000-30,000.

Embodiment 2

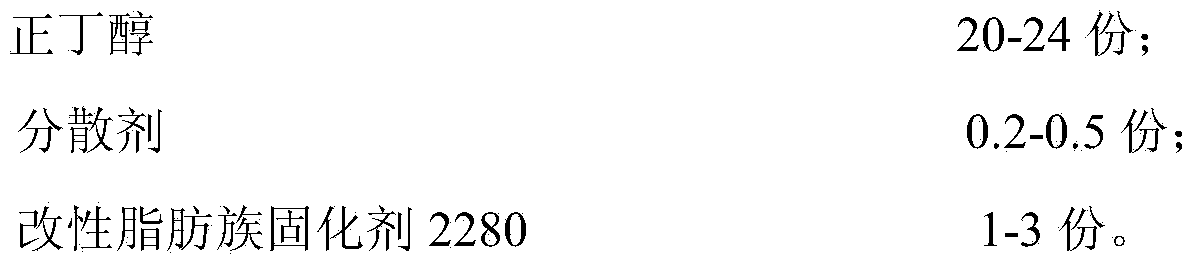

[0022] A high corrosion-resistant shop primer, comprising the following components in parts by weight:

[0023]

[0024] The dispersant is a polymer polyurethane polymer with a molecular weight of 10,000-30,000.

Embodiment 3

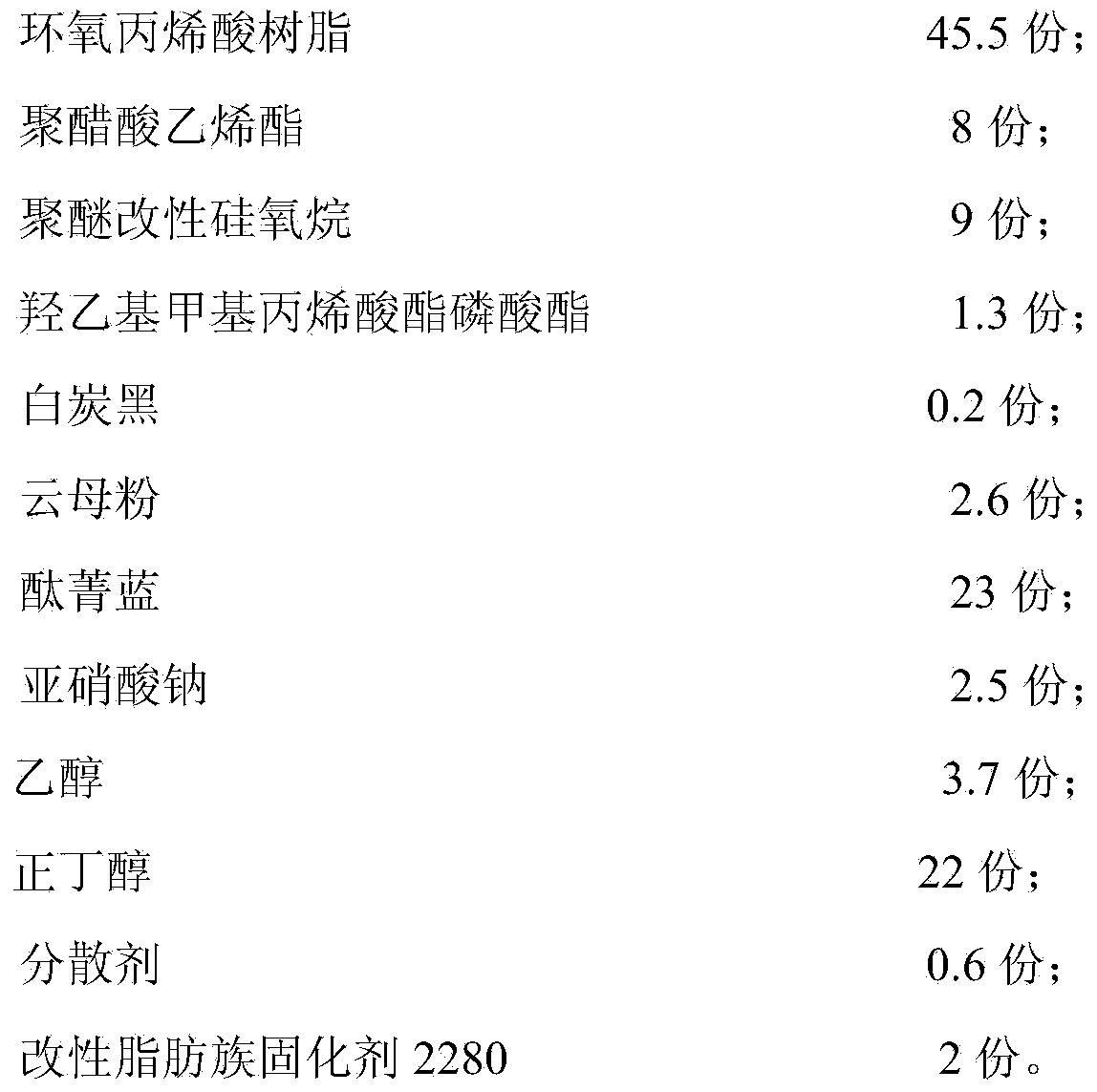

[0026] A high corrosion-resistant shop primer, comprising the following components in parts by weight:

[0027]

[0028]

[0029] The dispersant is a polymer polyurethane polymer with a molecular weight of 10,000-30,000.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com