Self-cleaning anti-fouling hydrophobic membrane layer based on enamel surface and preparation method thereof

A hydrophobic film layer, enamel technology, applied in the coating, metal material coating process and other directions, can solve the problems that have not been reported in the research, and achieve the effect of excellent chemical stability of acid resistance and improvement of hydrophobic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

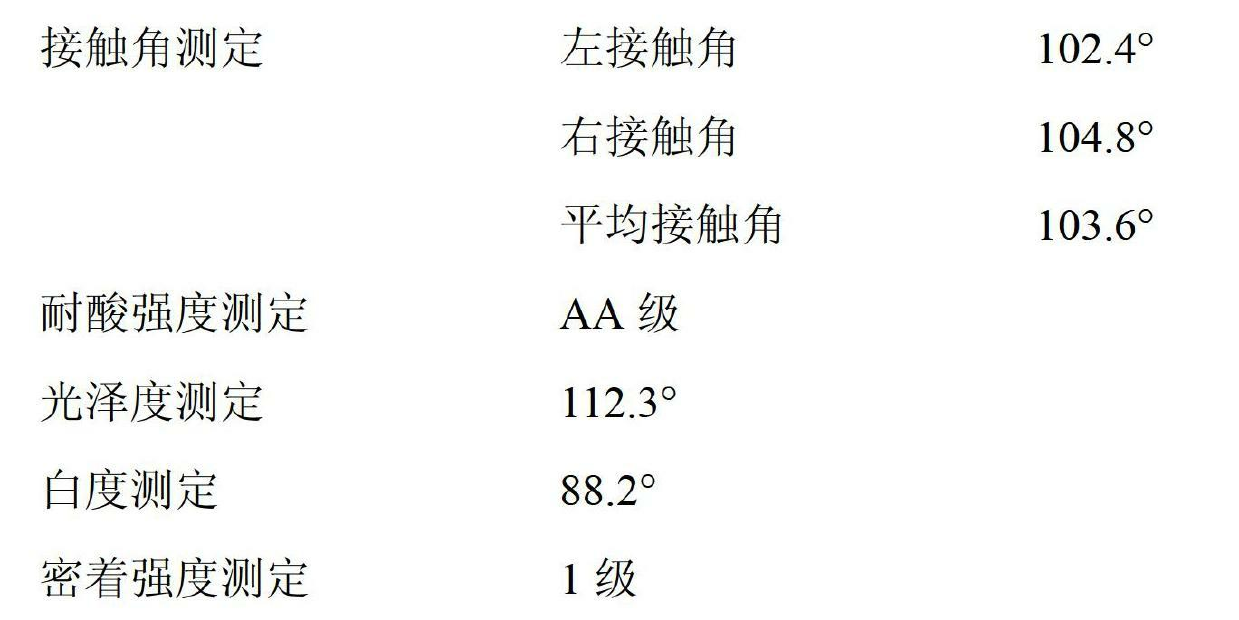

Examples

Embodiment 1

[0039] (1) Weigh each raw material according to the volume percentage of the following components:

[0040]

[0041] (2) Pour the weighed anhydrous ethanol and ammonia water into the beaker, stir for 5 minutes, seal the mouth of the beaker after mixing, and magnetically stir for 140 minutes;

[0042] (3) Gradually add weighed orthosilicate ethyl ester dropwise into the beaker after magnetic stirring, and keep magnetic stirring during the dropping process, and the stirring time is 80 minutes after the dropping is completed;

[0043] (4) After stirring, place the enamel substrate as described in Table 1 in the beaker solution and soak for 60 minutes, take it out and put it in a constant temperature oven at 60°C, keep it warm for 95 minutes, then use tweezers to pick up the enamel substrate and quickly put it into a drying dish , naturally cooled with room temperature;

[0044] (5) Take out the enamel substrate sample from the drying dish and place it in a cool and dry place ...

Embodiment 2

[0049] (1) Weigh each raw material according to the volume percentage of the following components:

[0050]

[0051] (2) Pour the weighed anhydrous ethanol, ammonia + hydrochloric acid (the volume ratio of ammonia to hydrochloric acid is 95%:5%) into the beaker, stir for 3 minutes, seal the mouth of the beaker after mixing, and magnetically stir for 40 minutes;

[0052] (3) Gradually add weighed tetraethyl orthosilicate dropwise into the beaker after magnetic stirring, and keep magnetic stirring during the dropping process, and the stirring time is 58 minutes;

[0053] (4) After stirring, place the enamel substrate in the beaker solution and soak for 60 minutes, take it out and put it in a constant temperature oven with a temperature of 64°C, keep it warm for 97 minutes, then use tweezers to pick up the enamel substrate and quickly put it into a drying dish. cool down;

[0054] (5) Take out the enamel substrate sample from the drying dish and place it in a cool and dry pl...

Embodiment 3

[0059] (1) Weigh each raw material according to the volume percentage of the following components:

[0060]

[0061] (2) Pour the weighed anhydrous ethanol, ammonia + hydrochloric acid (the volume ratio of ammonia to hydrochloric acid is 85%:15%) into the beaker, stir for 7 minutes, seal the mouth of the beaker after mixing, and magnetically stir for 82 minutes;

[0062] (3) Gradually add weighed tetraethyl orthosilicate dropwise into the beaker after magnetic stirring, and keep magnetic stirring during the dropping process, and the stirring time is 60 minutes;

[0063] (4) After stirring, place the enamel substrate in the beaker solution and soak for 75 minutes, take it out and put it in a constant temperature oven at 55°C, keep it warm for 120 minutes, then use tweezers to pick up the enamel substrate and quickly put it in a drying dish, let it cool down naturally at room temperature cool down;

[0064] (5) Take out the enamel substrate sample from the drying dish and p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com