Shop primer curing agent

A shop primer and curing agent technology, applied in the direction of coating, etc., can solve the problems of poor anti-corrosion performance of coatings, poor thermal stability of primers, affecting coating anti-corrosion performance, etc., to achieve excellent anti-corrosion performance, strong stability, and excellent adhesion strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

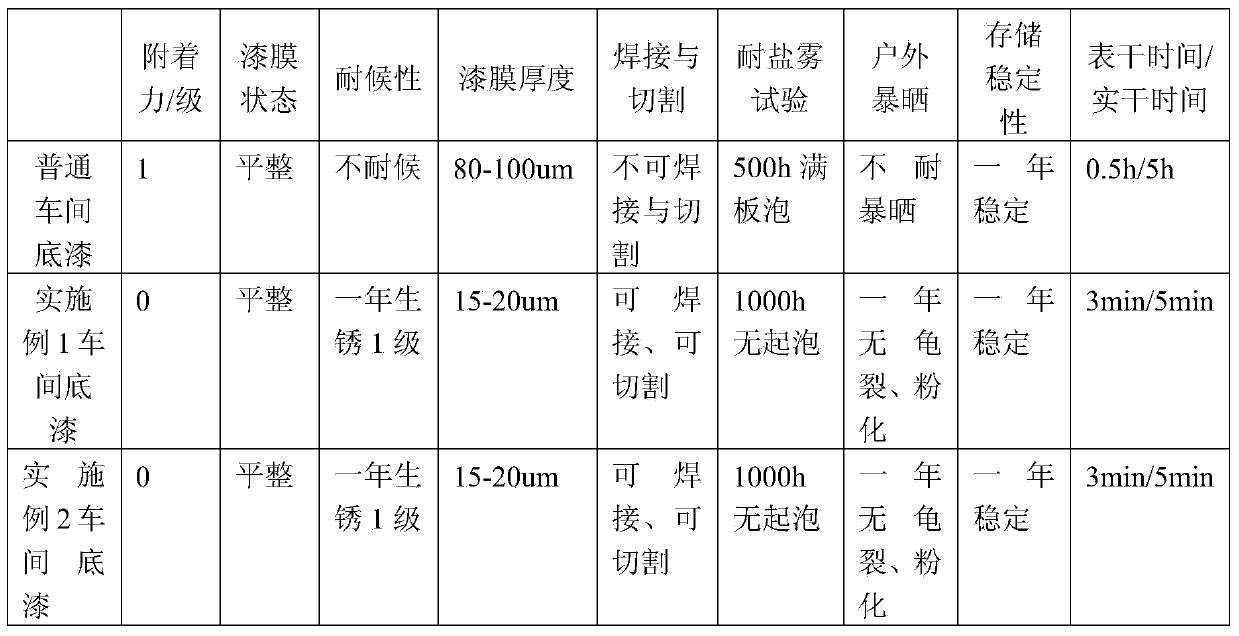

Examples

Embodiment 1

[0019] A shop primer curing agent is made by the following preparation method:

[0020] Step 1: Add the two reaction liquids of ethyl silicate and absolute ethanol into the reaction kettle in turn, and stir for 5 minutes to obtain the mixed liquid A;

[0021] Step 2: Add distilled water, 2N hydrochloric acid, and absolute ethanol in sequence to the drip tank of the liquid dripping device for pre-mixing, set the flow controller in the liquid dripping device, and control the pre-mixed solution in the dripping device for 60 minutes Add it to the mixed solution A in the reaction kettle at a uniform speed; while setting the flow controller, set the lower limit position of the liquid level control sensor in the drip tank to test the drop of the liquid level in advance; When the liquid level drops to the preset lower limit position, the liquid level control sensor starts to emit sound and light alarm to remind the operator that step 2 is completed and they should quickly enter the ne...

Embodiment 2

[0025] A shop primer curing agent is made by the following preparation method:

[0026] Step 1: Add the two reaction liquids of ethyl silicate and absolute ethanol into the reaction kettle in turn, and stir for 10 minutes to obtain the mixed liquid A;

[0027] Step 2: Add distilled water, 2N hydrochloric acid, and absolute ethanol in sequence to the drip tank of the liquid dripping device for pre-mixing, set the flow controller in the liquid dripping device, and control the pre-mixed solution in the dripping device for 90 minutes Add it to the mixed solution A in the reaction kettle at a uniform speed; while setting the flow controller, set the lower limit position of the liquid level control sensor in the drip tank to test the drop of the liquid level in advance; When the liquid level drops to the preset lower limit position, the liquid level control sensor starts to emit sound and light alarm to remind the operator that step 2 is completed and they should quickly enter the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com