Surface-discharge ceramic substrate applied to optical pumping source and manufacturing method of surface-discharge ceramic substrate

A surface discharge and ceramic substrate technology, applied in the field of functional materials and their preparation, can solve the problem that the anti-ablation performance cannot meet the requirements of the substrate's anti-discharge plasma ablation, the surface photodischarge optical pump source has a short operating life, and the high power is limited. Repeated frequency XeF applications, etc., to achieve the effects of easy nucleation and growth, optimization of process conditions and parameters, and small residual thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

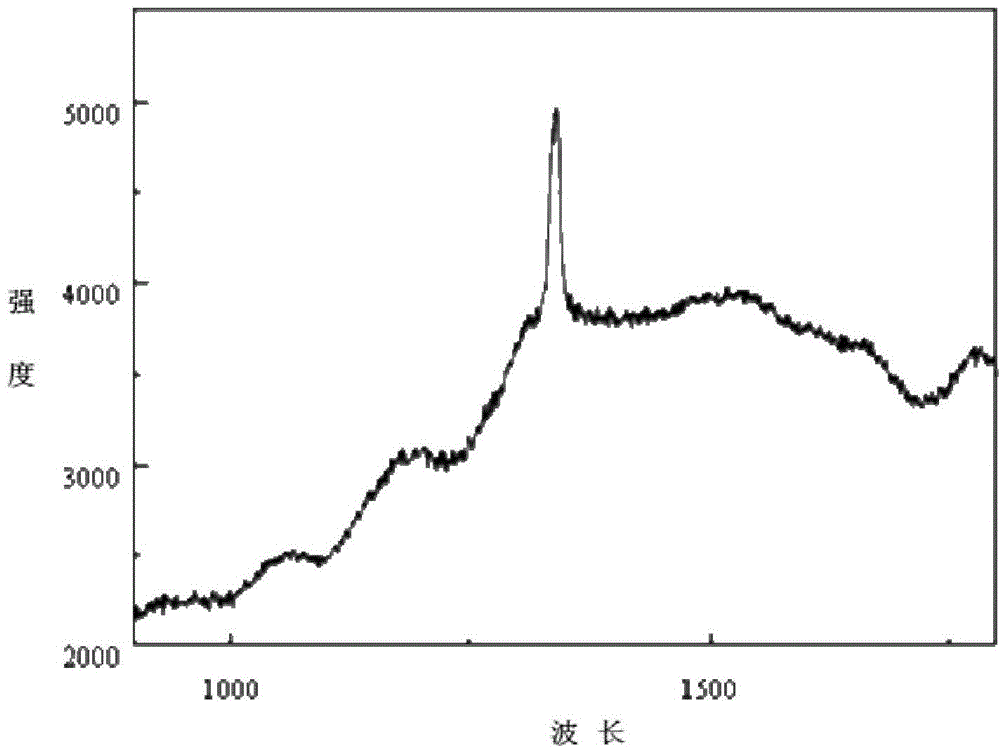

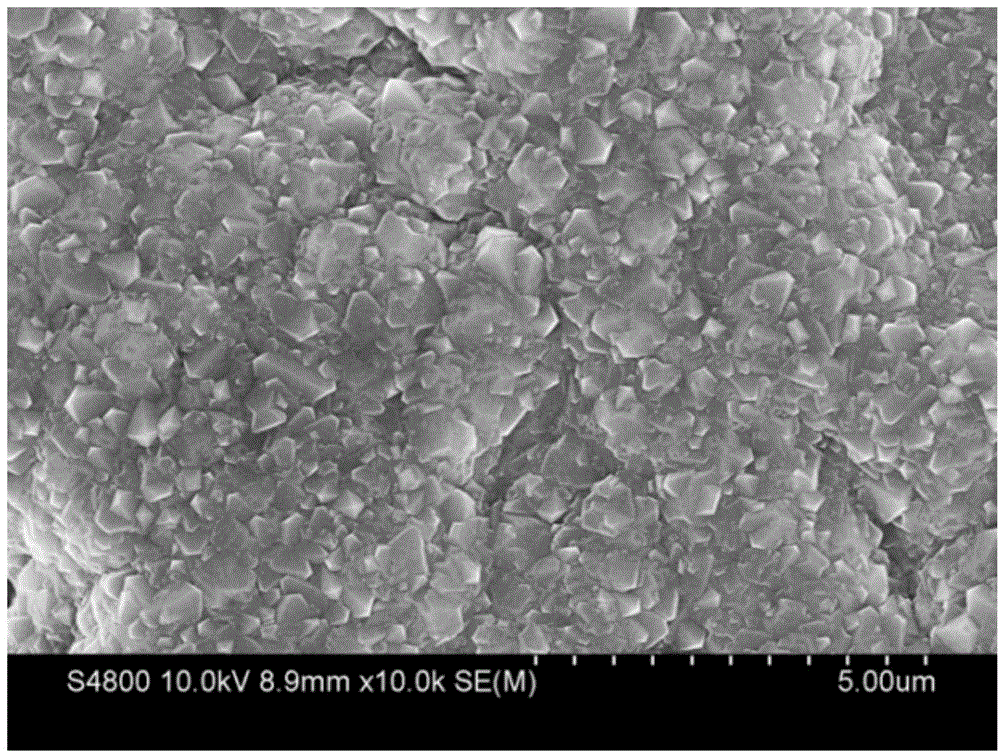

[0036] Kind of like figure 1 , figure 2 with Figure 4 The alumina surface discharge ceramic substrate used for the optical pump source of the present invention is shown. The surface discharge ceramic substrate has a double-layer superimposed structure and includes an alumina ceramic body 2 (in which α-Al 2 O 3 The content is 95%) and the diamond ablation resistant coating 1 (diamond continuous film) deposited on the alumina ceramic body 2. In this embodiment, the thickness of the diamond ablation resistant coating 1 is 40.0 μm, and the surface resistance is 1.5×10 12 Ω·cm.

[0037] The preparation method of the surface discharge ceramic substrate in this embodiment includes the following steps:

[0038] (1) Choose coarse-diameter diamond powder with a particle size of 4.0μm and fine-diameter diamond powder with a particle size of 0.8μm. The mass ratio of acetone, coarse-diameter diamond powder, fine-diamond diamond powder, and magnesium carbonate is 75 :1:10:14:1, mix well, and ...

Embodiment 2

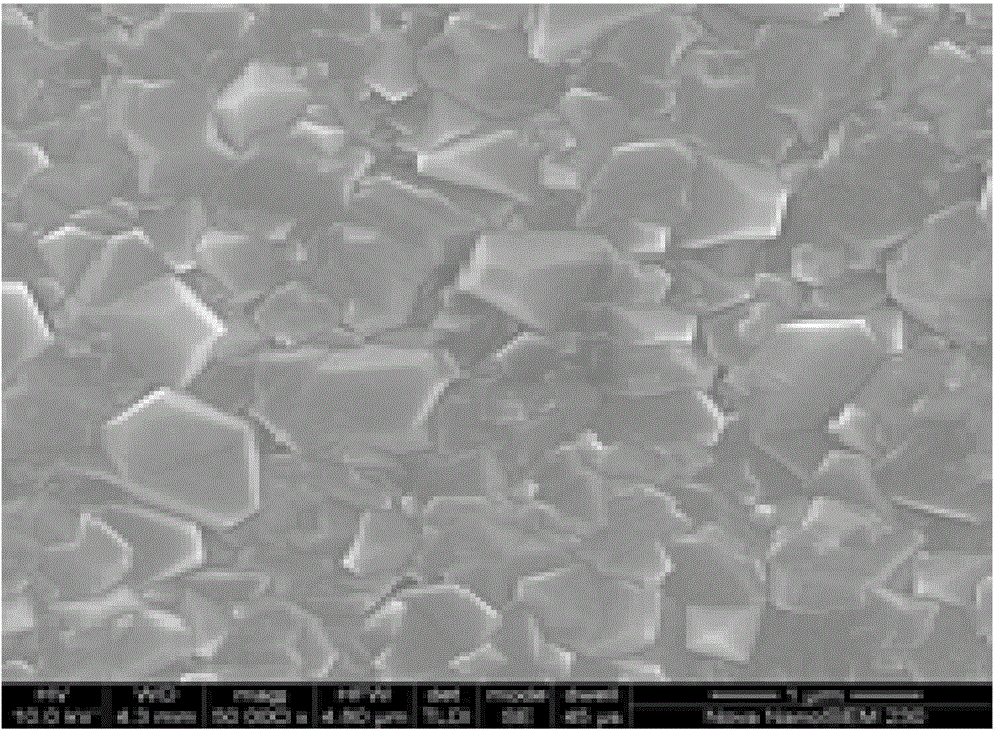

[0044] Kind of like image 3 , Figure 4 The beryllium oxide surface discharge ceramic substrate for an optical pump source of the present invention is shown. The surface discharge ceramic substrate has a double-layer superimposed structure and includes a beryllium oxide ceramic body 2 and a diamond ablation resistant deposited on the beryllium oxide ceramic body 2 Coating 1 (diamond continuous film). In this embodiment, the thickness of the diamond ablation resistant coating 1 is 80.0 μm, and the surface resistance is 7.2×10 12 Ω·cm.

[0045] The preparation method of the surface discharge ceramic substrate in this embodiment includes the following steps:

[0046] (1) Select coarse-diameter diamond powder with a particle size of 1.0μm and fine-diameter diamond powder with a particle size of 0.1μm. The mass ratio of acetone, coarse-diameter diamond powder, fine-diamond diamond powder, and magnesium carbonate is 85. :6:12:2 is mixed thoroughly to obtain a diamond suspension;

[004...

Embodiment 3

[0052] Kind of like Figure 4 The alumina surface discharge ceramic substrate used for the optical pump source of the present invention is shown. The surface discharge ceramic substrate has a double-layer superimposed structure and includes an alumina ceramic body 2 (in which α-Al 2 O 3 The content is 99%) and the diamond ablation resistant coating 1 (diamond continuous film) deposited on the alumina ceramic body 2. In this embodiment, the thickness of the diamond ablation resistant coating 1 is 100.0 μm, and the surface resistance is 9.0×10 12 Ω·cm.

[0053] The preparation method of the surface discharge ceramic substrate in this embodiment includes the following steps:

[0054] (1) Choose coarse-diameter diamond powder with a particle size of 5.0μm and fine-diameter diamond powder with a particle size of 0.6μm. The mass ratio of acetone, coarse-diameter diamond powder, fine-diamond diamond powder, and magnesium carbonate is 80 :5:14:1 Mix thoroughly and evenly, and then prepare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com