Traditional Chinese medicine soft capsule auxiliary material with universality and method for preparing traditional Chinese medicine soft capsules

A soft capsule and universal technology, applied in the field of medicine, can solve problems such as prolonged disintegration time limit, poor drug stability, and large amount of excipients, and achieve the effects of good drug stability, expanded application range, and increased specific gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

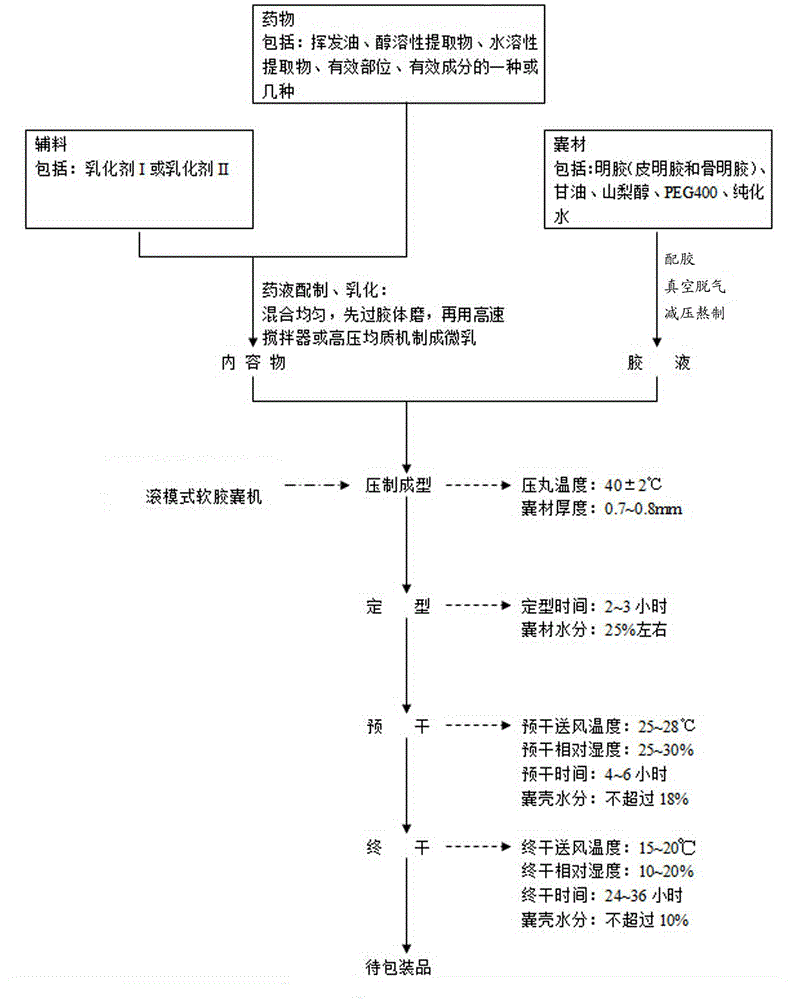

Image

Examples

Embodiment 1

[0040] Molding process of Lingyang Ganmao soft capsule preparation

[0041] 1. Preparation formula

[0042] Main ingredients: dry extract powder (water extract of forsythia and nepeta paniculae after extraction of volatile oil, water extract of honeysuckle, platycodon, light bamboo leaf, licorice, alcohol extract of burdock seed and light tempeh) 220g, Antelope horn powder 6.0g, menthol 1.5g, peppermint oil 0.75ml, forsythia and nepeta volatile oil 3.0ml.

[0043] Excipients: Emulsifier I 218.75g.

[0044] Specifications: 0.45g per capsule, made into 1000 capsules.

[0045] 2. Preparation of emulsifier Ⅰ

[0046] Formula: Soybean Oil 80%, Soy Lecithin 8%, Hydrogenated Soybean Oil 6%, Beeswax 6%.

[0047] Preparation method: Weigh 1 / 4 of soybean oil in proportion, add beeswax, soybean lecithin, and hydrogenated soybean oil, heat to 60°C to melt completely, mix well, then add the remaining soybean oil, mix well, pass Colloid mill, made into emulsion, that is.

[0048] 3. C...

Embodiment 2

[0078] Preparation process of Yimaikang soft capsule

[0079] 1. Preparation formula

[0080] Main ingredients: 160g of dry extract powder (ethanol extract of breviscapine).

[0081] Excipients: Emulsifier I 290g.

[0082] Specifications: 0.45g per capsule, made into 1000 capsules.

[0083] 2. Preparation of emulsifier Ⅰ

[0084] Formula: Soybean Oil 82%, Soy Lecithin 6%, Hydrogenated Soybean Oil 6%, Beeswax 6%.

[0085] Preparation method: Weigh 1 / 4 of soybean oil in proportion, add beeswax, soybean lecithin, and hydrogenated soybean oil, heat to 62°C to melt completely, mix well, then add remaining soybean oil, mix well, pass Colloid mill, made into emulsion, that is.

[0086] 3. Content preparation

[0087] Take emulsifier Ⅰ, heat to 48°C, add breviscapine dry extract powder, mix evenly, first pass through a colloid mill, and then use a high-pressure homogenizer to form a microemulsion.

[0088] 4. Preparation of capsule material (glue)

[0089] Formula: 100 parts o...

Embodiment 3

[0116] Forming process of Yixindone soft capsule preparation

[0117] 1. Preparation formula

[0118] Main ingredients: Hawthorn leaf extract 35g.

[0119] Excipients: Emulsifier I 145g.

[0120] Specifications: 0.18g per capsule, made into 1000 capsules.

[0121] 2. Preparation of emulsifier Ⅰ

[0122] Formula: Soybean Oil 88%, Soy Lecithin 4%, Hydrogenated Soybean Oil 4%, Beeswax 4%.

[0123] Preparation method: Weigh 1 / 4 of soybean oil in proportion, add beeswax, soybean lecithin, and hydrogenated soybean oil, heat to 65°C to melt completely, mix well, then add the remaining soybean oil, mix well, pass Colloid mill, made into emulsion, that is.

[0124] 3. Content preparation

[0125] Take emulsifier Ⅰ, heat to 46°C, add hawthorn leaf extract, mix evenly, first pass through colloid mill, and then use high-pressure homogenizer to make microemulsion.

[0126] 4. Preparation of capsule material (glue)

[0127] Formula: 100 parts of gelatin (hide glue), 4 parts of gelat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com