Methylamine halogenated plumbate compound large-size crystal growth method and device

A technology of methylamine halide lead salt and growth method, which is applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of testing the anisotropic physical properties of large-sized crystals without compounds, and achieve easy large-scale High-quality crystals, easy to achieve operating conditions, and avoid the effect of stray crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1. Crystal growth device

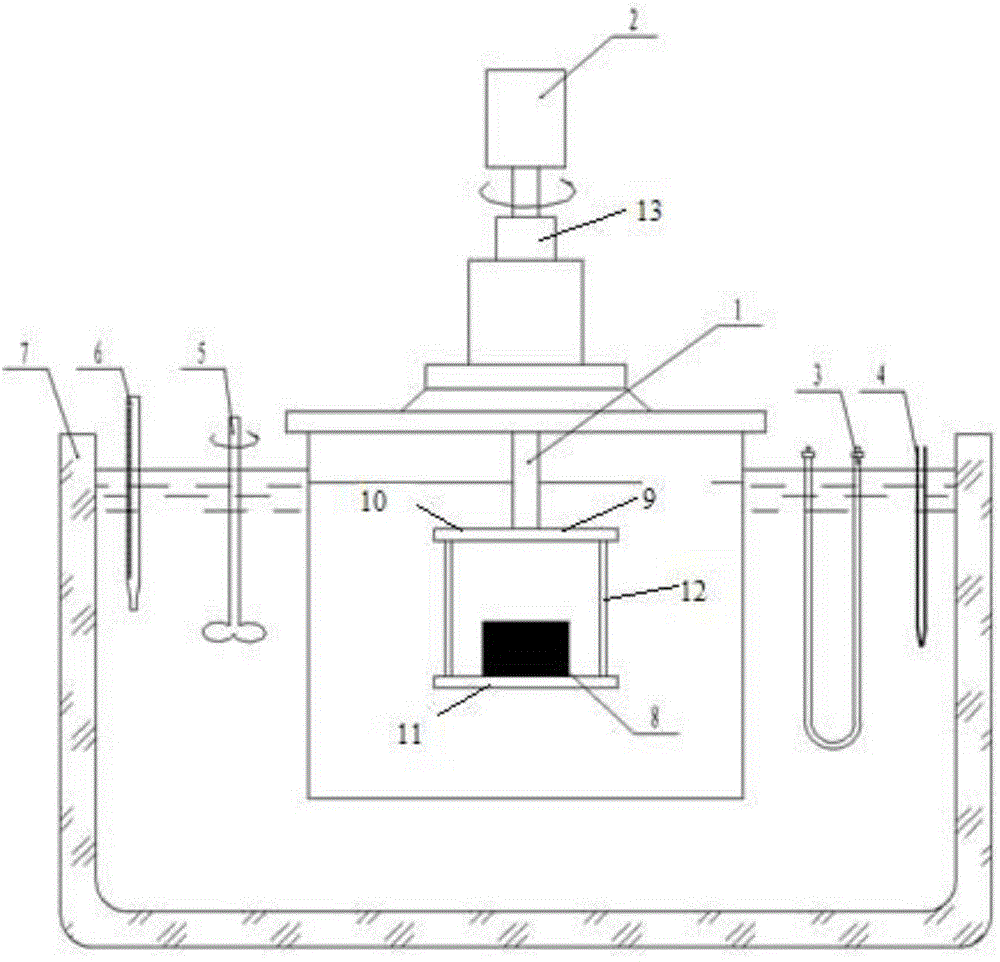

[0052] A kind of methylamine type lead halide salt large-size crystal growth device, the structure is as follows figure 1 As shown, a seed crystal rod 1 driven by a rotating motor 2 is vertically arranged in the middle of the water tank 7. The lower end of the seed crystal rod 1 is connected to a seed crystal holder 9 which is composed of upper and lower parallel disks 10, 11 And the cage structure formed by the vertical support rods 12 connecting the two discs, the lower disc 11 is the seed crystal plate; in the water tank 7, one side of the seed crystal rod 1 is provided with a heater 3 and a temperature sensor 4 in order from the inside to the outside. A paddle stirrer 5 and a thermometer 6 are arranged on the opposite side from the inside to the outside. The rotating motor 2 is directly and fixedly connected with the rotating stirrer 13, and the seed crystal rod 1 is fixed on the rotating stirrer 13. The device heats the solution...

Embodiment 2

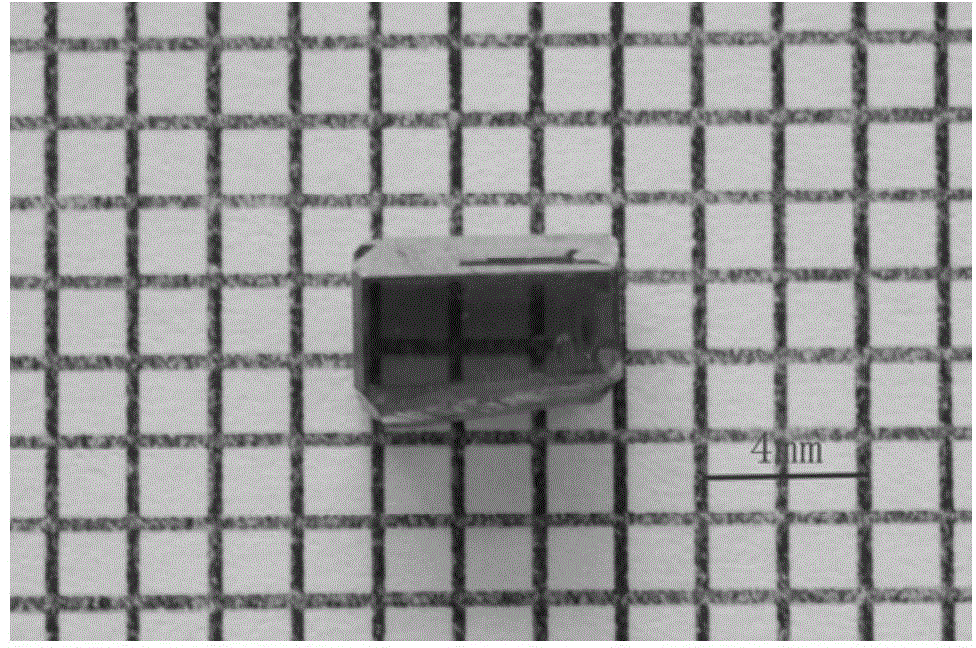

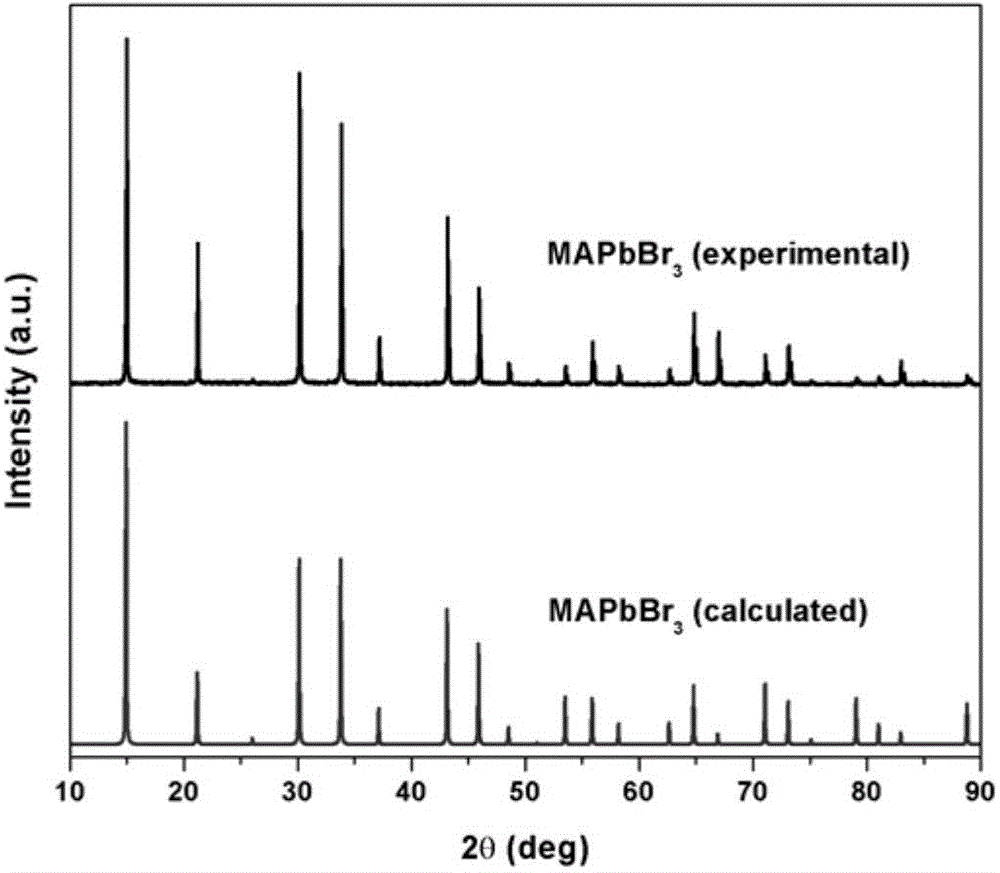

[0053] Example 2: Large size CH 3 NH 3 PbBr 3 Crystal growth

[0054] a. Methylamine bromide (CH 3 NH 3 Br) synthetic preparation: in an ice water bath, CH 3 NH 2 The aqueous solution was added to the HBr solution and reacted for 3.5 hours; CH 3 NH 2 :HBr=1.5:1 molar ratio. The mass percentage concentration of the methylamine aqueous solution is 30 wt%, and the mass percentage concentration of the HBr solution is 40 wt%.

[0055] After rotary evaporation with a vacuum rotary evaporator, white methylamine bromide is obtained. Add anhydrous ether to the obtained brominated methylamine and recrystallize 3 times to obtain white CH 3 NH 3 Br. Will get the white CH 3 NH 3 Br, placed in a vacuum drying oven for 2 hours, to obtain colorless CH 3 NH 3 Br crystals.

[0056] b. In a 300cm×30cm constant temperature water tank, accurately weigh Pb(CH 3 COOH) 2 ·3H 2 O was added to the 40wt% HBr solution to obtain a colorless and transparent solution.

[0057] c. Accurately weigh the CH prepared ...

Embodiment 3

[0059] Example 3. Large size CH 3 NH 3 PbI 3 Crystal growth

[0060] a. Methylamine iodide (CH 3 NH 3 I) Synthesis

[0061] Put CH in an ice water bath 3 NH 2 The aqueous solution is added to the HI solution, CH 3 NH 2 :HI=1.2:1 molar ratio, react for 4 hours. The mass percentage concentration of the methylamine aqueous solution is 30 wt%, and the mass percentage concentration of the HI solution is 40 wt%.

[0062] After rotary evaporation with a vacuum rotary evaporator, white methylamine iodide was obtained. Add anhydrous ether to the obtained methylamine iodide and recrystallize 3 times to obtain white CH 3 NH 3 I. Will get the white CH 3 NH 3 I, put it in a vacuum drying oven for several hours, and finally get colorless CH 3 NH 3 I crystal.

[0063] b. In a constant temperature water tank (300cm×30cm), accurately weigh Pb(CH 3 COOH) 2 ·3H 2 O was added to the 45wt% HI solution to obtain a yellow transparent solution.

[0064] c. Accurately weigh the CH prepared in step a accordin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com